12

Temposonics

®

GB-Series SSI

Operation Manual

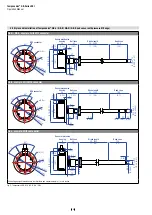

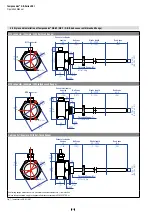

Fig. 12:

Notice for threaded flange M18×1.5-6g based on DIN ISO 6149-1

•

Note the fastening torque of 50 Nm.

•

Seat the flange contact surface completely on the cylinder mounting

surface.

• The cylinder manufacturer determines the pressure-resistant

gasket (copper gasket, O-ring, etc.).

• The position magnet should not grind on the sensor rod.

•

The piston rod drilling (≥ Ø 13 mm (≥ Ø 0.52 in.)) depends on the

pressure and piston speed.

• Adhere to the information relating to operating pressure.

• Protect the sensor rod against wear.

Notice for metric threaded flange

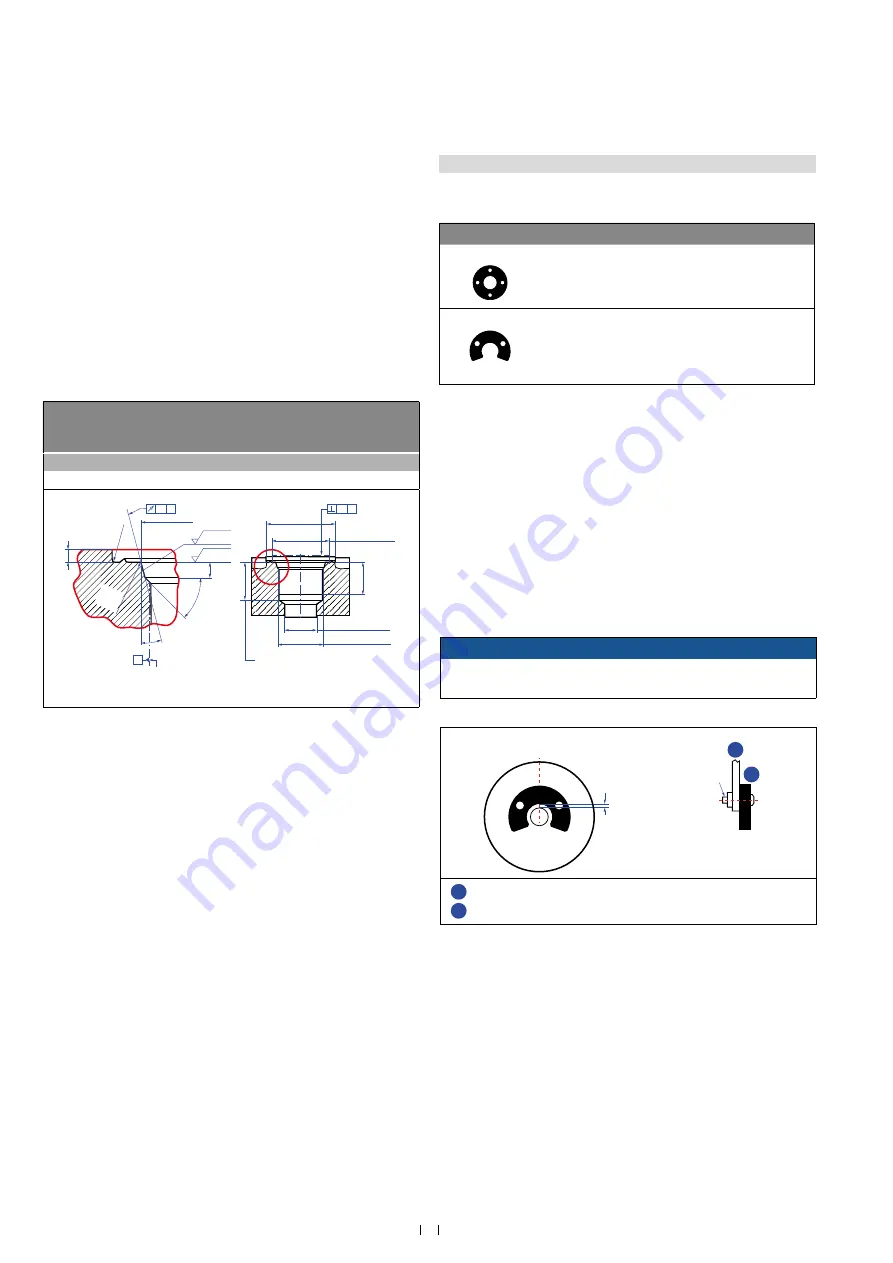

4.4 Magnet installation

Typical use of magnets

Magnet

Benefits

Ring magnets

•

Rotationally symmetrical magnetic field

U-magnets

• Height tolerances can be compensated

Mounting ring magnets and U-magnets

Install the magnet using non-magnetic material for mounting

device, screws, spacers etc.. The magnet must not grind on

the sensor rod. Alignment errors are compensated via the air gap.

•

Permissible surface pressure: Max. 40 N/mm

2

•

Fastening torque for M4 screws: 1 Nm; use washer, if necessary

• Minimum distance between position magnet and any magnetic

material has to be 15 mm (0.6 in.) (Fig. 15).

• If no other option exists and magnetic material is used, observe the

specified dimensions (Fig. 15).

Fig. 13:

Typical use of ring magnets and U-magnets

NOTICE

Mount ring magnets and U-magnets concentrically.

Do not exceed the maximum acceptable gap.

Fig. 14:

Mounting of U-magnet, part no. 251 416-2

Controlling design dimensions are in millimeters and measurements in ( ) are in inches

Thread

(d

1

×P)

d

2

d

3

d

4

d

5

+0.1

0

L

1

+0.4

0

L

2

L

3

L

4

Z°

±1°

GB-M

M18×1.5-6g ≥ 65

≥ 13

24.5

19.8

2.4

28.5

2 26

15°

Ød

5

Ra 3.2

Ra 3.2

Pitch diameter

A

A

Thread

(d

1

× P)

Ød

3

(Reference)

A

Ød

2

Ød

4

(Gauging)

This dimension applies when

tap drill cannot pass through

entire boss.

≤ R0.4

R0.3 R0.1

Z°

45

° ±

5°

L

3

L

1

L

2

L

4

A

0.1

A

0.2

Controlling design dimensions are in millimeters

M4

1

2

Air gap

Concentric mounting

of U-magnet

Part no. 201 553:

3 ±1 (0.12 ±0.04)

Part no. 251 416-2:

1.75 ±1 (0.07 ±0.04)

U-magnet

Non-magnetic mounting plate and fasteners

1

2