TABLE OF CONTENTS

SECTION 1 GENERAL INFORMATION ............................................................................................... 1

1.1 INTRODUCTION .......................................................................................................................................................... 1

1.2 RESTRICTION ON USE ................................................................................................................................................. 1

1.3 CAUTIONARY SYMBOLS .............................................................................................................................................. 2

SECTION 2 TECHNICAL INFORMATION............................................................................................. 3

2.1 SPECIFICATIONS .......................................................................................................................................................... 3

2.2 MRO O

UTPUT

W

ATER

Q

UALITY

........................................................................................................................................ 4

2.3 TEMPERATURE CORRECTED MRO PRODUCTION RATES ............................................................................................. 4

SECTION 3 COMPONENTS AND SCHEMATICS .................................................................................. 5

3.1 EXTERNAL FRONT VIEW .............................................................................................................................................. 5

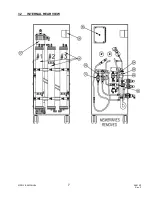

3.2 INTERNAL REAR VIEW ................................................................................................................................................. 7

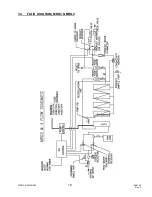

3.3 ELECTRICAL DIAGRAM, MRO3 & MRO4 ..................................................................................................................... 9

SECTION 4 MRO STARTUP & OPERATION ...................................................................................... 11

4.1 CAUTION ................................................................................................................................................................... 11

4.2 SAFETY FEATURES ..................................................................................................................................................... 13

4.3 INITIAL STARTUP ....................................................................................................................................................... 14

4.4 SYSTEM SHUTDOWN ................................................................................................................................................ 16

SECTION 5 DISINFECTING THE SYSTEM .......................................................................................... 17

5.1 DISINFECTING THE SYSTEM ...................................................................................................................................... 17

5.2 DISINFECTING AN MRO CONNECTED TO A “LARGE” LOOP ....................................................................................... 23

5.3 A WORD ABOUT HYDROGEN PEROXIDE/PEROXYACETIC ACID ................................................................................. 24

5.4 MEMBRANE FLUSH FEATURE (AUTO FLUSH) ............................................................................................................ 25

SECTION 6 MRO CONTROLLER ...................................................................................................... 26

6.1 FRONT PANEL CONTROLS AND INDICATORS ............................................................................................................ 26

6.2 CONTROLLER OPERATION ........................................................................................................................................ 27

6.3 CONTROLLER ADJUSTMENTS.................................................................................................................................... 30

6.4 STANDARD SETPOINTS ............................................................................................................................................. 33

6.5 TO DISPLAY OR CHANGE SETPOINTS ......................................................................................................................... 35

SECTION 7 EXTERNAL WIRE INSTALLATION ................................................................................... 36

SECTION 8 MAINTENANCE ............................................................................................................ 37

8.1 MAINTAINING THE SYSTEM ...................................................................................................................................... 37

8.2 PT401 ANTI-SCALANT ............................................................................................................................................... 38

8.3 MEMBRANE MAINTENANCE INSTRUCTIONS ............................................................................................................ 38

8.4 EXCHANGE PREPERATION ........................................................................................................................................ 38

8.5 MEMBRANE EXCHANGE ........................................................................................................................................... 38

8.6 AMERIWATER CLEAN IN PLACE (CIP) ........................................................................................................................ 40

SECTION 9 TROUBLESHOOTING AND REPAIR ................................................................................. 41

9.1 TROUBLESHOOTING CHART ....................................................................................................................................... 41

9.2 CONTROLLER TROUBLESHOOTING ........................................................................................................................... 44

9.3 PUMP REPAIR ........................................................................................................................................................... 46

9.4 INSTALLING A REPLACEMENT PUMP ASSEMBLY ...................................................................................................... 46

9.5 SOLENOID TEST PROCEDURE .................................................................................................................................... 47

9.6 SOLENOID VALVE REPLACEMENT ............................................................................................................................. 47

Содержание MRO3

Страница 8: ...MRO 3 4 MANUAL 5 98 0140 Rev F SECTION 3 COMPONENTS AND SCHEMATICS 3 1 EXTERNAL FRONT VIEW...

Страница 10: ...MRO 3 4 MANUAL 7 98 0140 Rev F 3 2 INTERNAL REAR VIEW...

Страница 12: ...MRO 3 4 MANUAL 9 98 0140 Rev F 3 3 ELECTRICAL DIAGRAM MRO3 MRO4...

Страница 13: ...MRO 3 4 MANUAL 10 98 0140 Rev F 3 4 FLUID DIAGRAM MRO3 MRO4...

Страница 34: ...MRO 3 4 MANUAL 31 98 0140 Rev F FIGURE 6 2...

Страница 35: ...MRO 3 4 MANUAL 32 98 0140 Rev F FIGURE 6 3...

Страница 52: ...MRO 3 4 MANUAL 49 98 0140 Rev F SECTION 11 MRO3 4 SPARE PARTS LISTING...

Страница 53: ...MRO 3 4 MANUAL 50 98 0140 Rev F...