SERVICING

39

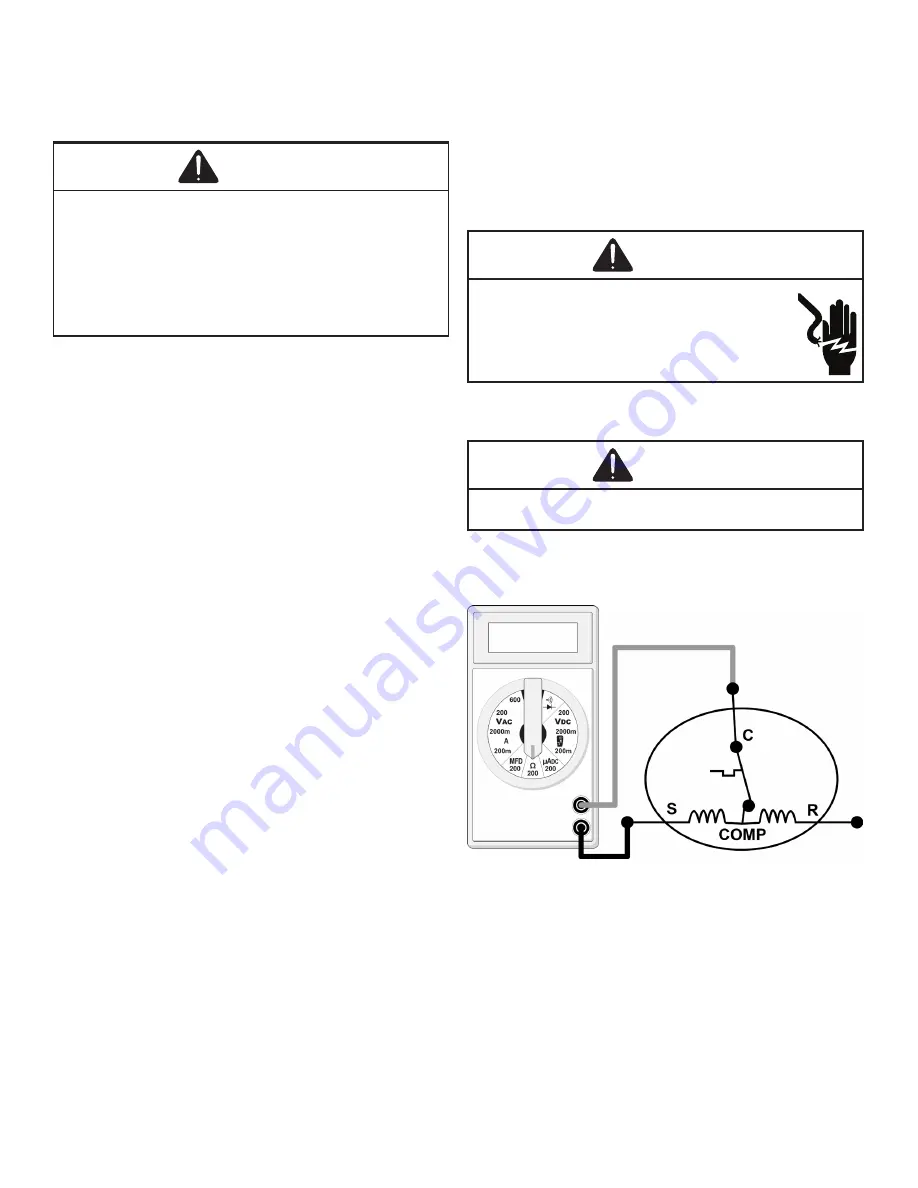

Checking Compressor

WARNING

Hermetic compressor electrical terminal

venting can be dangerous. When insulating

material which supports a hermetic compressor

or electrical terminal suddenly disintegrates

due to physical abuse or as a result of an

electrical short between the terminal and

the compressor housing, the terminal may be

expelled, venting the vapor and liquid contents

of the compressor housing and system.

If the compressor terminal PROTECTIVE COVER and

gasket (if required) are not properly in place and secured,

there is a remote possibility if a terminal vents, that the

vaporous and liquid discharge can be ignited, spouting

flames several feet, causing potentially severe or fatal

injury to anyone in its path.

This discharge can be ignited external to the compressor

if the terminal cover is not properly in place and if the

discharge impinges on a sufficient heat source.

Ignition of the discharge can also occur at the venting

terminal or inside the compressor, if there is sufficient

contaminant air present in the system and an electrical arc

occurs as the terminal vents.

Ignition cannot occur at the venting terminal without the

presence of contaminant air, and cannot occur externally

from the venting terminal without the presence of an

external ignition source.

Therefore, proper evacuation of a hermetic system is

essential at the time of manufacture and during servicing.

To reduce the possibility of external ignition, all open

flame, electrical power, and other heat sources should be

extinguished or turned off prior to servicing a system.

If the following test indicates shorted, grounded or open

windings, see procedures for the next steps to be taken.

Resistance Test

Each compressor is equipped with an internal overload.

The line break internal overload senses both motor

amperage and winding temperature. High motor

temperature or amperage heats the disc causing it to open,

breaking the common circuit within the compressor on

single phase units.

Heat generated within the compressor shell, usually due to

recycling of the motor, high amperage or insufficient gas to

cool the motor, is slow to dissipate. Allow at least three to

four hours for it to cool and reset, then retest.

Fuse, circuit breaker, ground fault protective device, etc.

has not tripped.

WARNING

High Voltage!

Disconnect all power before servicing

or installing. Multiple power sources

may be present. Failure to do so may

cause property damage, personal injury

or death.

1. Remove the leads from the compressor terminals.

WARNING

See warnings before removing compressor

terminal cover.

2. Using an ohmmeter, test continuity between terminals

S-R, C-R, and C-S, on single phase units.

Testing Compressor Windings

If either winding does not test continuous, replace the

compressor.

NOTE: If an open compressor is indicated, allow

ample time for the internal overload to reset before

replacing compressor.

Содержание ASXC16

Страница 4: ...PRODUCT IDENTIFICATION 4 ...

Страница 5: ...PRODUCT IDENTIFICATION 5 ...

Страница 70: ...SERVICING 70 PCBHR104 PCBHR105 ...