G A S C O M B I T H E R M

—

I N S T A L L A T I O N M A N U A L

#MN-28676

PG

. 21

®

C O M B I T HE R M

®

WAT E R S U P P LY & I N S TA L L AT I O N R E Q U I R E M E N T S

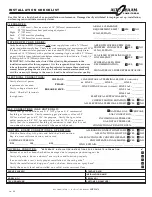

Flush the water line at the installation site before

connecting the oven to the water supply. A hose connector

is supplied for flexible hose connection to the

COLD

water source.

PIPE SEALING TAPE

(

TEFLON

®

)

MUST BE USED AT

ALL CONNECTION POINTS.

The use of a pipe

sealing compound is not recommended.

WAT E R R E Q U I R E M E N T S

TWO (2) COLD WATER INLETS - DRINKING QUALITY

ONE

(1)

TREATED WATER INLET

:

3/4" NPT*

ONE

(1)

UNTREATED WATER INLET

:

3/4" NPT*

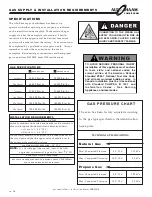

LINE PRESSURE

:

30 to 90 psi

2.8 to 6.2 bar

* Can manifold off of one 3/4" line

REFER TO PUBLISHED SPECIFIC WATER REQUIREMENTS

WATER DRAIN: 1-1/2"

CONNECTION WITH AIR GAP

NOTE:

BOTH TREATED AND UNTREATED WATER

CONNECTIONS MUST BE CONNECTED FOR PROPER

OPERATION OF THE OVEN. BOTH CONNECTIONS

CAN BE TREATED WATER, BUT SHOULD NEVER BE

CONNECTED TO ONLY UNTREATED WATER.

UNIONS OR FLEXIBLE LINES SHOULD BE USED TO

ALLOW FOR OVEN MOVEMENT WHEN BEING

SERVICED OR CLEANING IS NEEDED.

REFER TO DIMENSION DRAWINGS BEGINNING ON

PAGE 4 FOR PROPER INTAKE LOCATIONS.

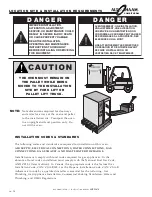

Incoming cold water

connection

T connection

Cold water line to

untreated oven

connection

Treated cold

water to treated

connection on oven

ONE SUGGESTED METHOD OF INSTALLATION

Water Filter

Cold water line to

filter or treatment

system