507788-01

Issue 2007

Page 18 of 20

Cabinet Insulation

DAMAGED INSULATION MUST BE REPAIRED OR

REPLACED

before the unit is put back into operation.

Insulation loses its insulating value when wet, damaged,

separated or torn.

IMPORTANT

Matte- or foil-faced insulation is installed in indoor

equipment to provide a barrier between outside air

conditions (surrounding ambient temperature and humidity)

and the varying conditions inside the unit. If the insulation

barrier is damaged (wet, ripped, torn or separated from the

cabinet walls), the surrounding ambient air will affect the

inside surface temperature of the cabinet.

The temperature/humidity difference between the inside

and outside of the cabinet can cause condensation on the

inside or outside of the cabinet which leads to sheet metal

corrosion and, subsequently, component failure.

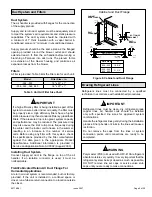

Repairing Damaged Insulation

Areas of condensation on the cabinet surface are an

indication that the insulation is in need of repair.

If the insulation in need of repair is otherwise in good

condition, the insulation should be cut in an X pattern,

peeled open, glued with an appropriate all-purpose glue

and placed back against the cabinet surface, being careful

to not overly compress the insulation so the insulation can

retain its original thickness. If such repair is not possible,

replace the insulation. If using foil-faced insulation, any

cut, tear, or separations in the insulation surface must be

taped with a similar foil-faced tape.

1. CUT INSULATION IN X PATTERN

2. APPLY GLUE

3. PRESS GLUED TABS AGAINST CABINET

GLUE - Make sure there is

full coverage of glue on the

metal or insulation so there

are no areas where air

pockets may form which

can lead to sweating.

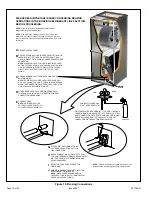

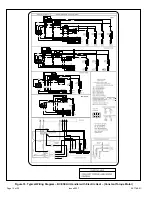

Figure 17. Recommended Blower Speed Taps