507788-01

Issue 2007

Page 16 of 20

Air Flow - Cooling Blower Speed

The cooling blower speed is factory configured to provide

correct air flow for an outdoor unit that matches the cooling

capacity rating of the air handler (Tap 3).

If the outdoor unit is smaller than the maximum cooling

capacity rating for the air handler, the cooling blower speed

may need to be changed. Refer to blower performance

ELECTRIC SHOCK HAZARD!

Disconnect all power supplies before

servicing.

Replace all parts and panels before

operating.

Failure to do so can result in death or

electrical shock.

WARNING

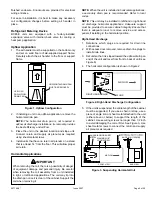

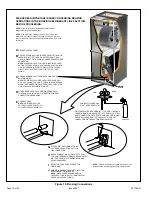

Adjusting Blower Speed

Motor Speed Taps

NOTE

-

Motor is programmed for a 45-second OFF delay

on all speed taps except TAP #1 (continuous fan speed).

These settings are for nominal tonnage match-ups with

the BCE5E

units. When matched with other sizes, it is

recommended that the CFM be adjusted to approximately

400 CFM per ton.

Tap

Operation

Remarks

1

Continuous fan

Continuous fan speed is

energized (24 volt input to G).

2

Lower tonnage

speed

Air flow set at 1/2 ton lower than

nominal capacity (e.g. if 3-ton

air handler is used with 2.5-ton

outdoor unit).

3

A/C or heat pump -

no electric heat

Air flow set at 400 SCFM per ton

at minimum static allowed.

4*

A/C or Heat pump

with electric heat

Air flow set at 400 SCFM per

ton at .5 static. Energized when

electric heat element has a call

for heat.

5

High static

applications

Air flow set at 400 cfm per ton

at .8 static. (Connect white wire

from blower relay to Tap 5 instead

of Tap 4)

* Tap 4 is minimum setting for electric heat

Table 5.

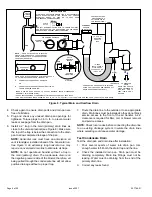

Checkout Procedures

NOTE:

Refer to outdoor unit installation instructions for

system start-up instructions and refrigerant charging

instructions.

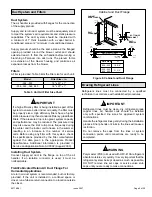

Pre-Start-Up Checks

• Is the air handler properly and securely installed?

•

If horizontally configured, is the unit sloped up to 5/8

inch toward drain lines?

• Will the unit be accessible for servicing?

• Has an auxiliary pan been provided under the unit

with separate drain for units installed above a finished

ceiling or in any installation where condensate overflow

could cause damage?

• Have ALL unused drain pan ports been properly

plugged?

• Has the condensate line been properly sized, run,

trapped, pitched, and tested?

• Is the duct system correctly sized, run, sealed, and

insulated?

•

Have all cabinet openings and wiring been sealed?

• Is the indoor coil factory-installed TXV properly sized

for the outdoor unit being used?

• Have all unused parts and packaging been disposed

of?

•

Is the filter clean, in place, and of adequate size?

•

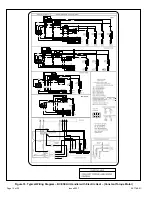

Is the wiring neat, correct, and in accordance with the

wiring diagram?

• Is the unit properly grounded and protected (fused)?

•

Is the thermostat correctly wired and in a good

location?

• Are all access panels in place and secure?

Check Blower Operation

1. Set thermostat to FAN ON.

2.

The indoor blower should turn on.

Check Unit Operation

1. Set thermostat to force a call for cooling (approximately

5ºF lower than the indoor ambient temperature).

2. The outdoor unit should turn on immediately.

3.

Check the air flow from a register to confirm that the

system is moving cooled air.

4.

Set the thermostat 5ºF higher than the indoor

temperature. The indoor blower and outdoor unit

should cycle off. Air handler should cycle off 45

seconds after the outdoor unit shuts off.