507787-01

Issue 2007

Page 4 of 22

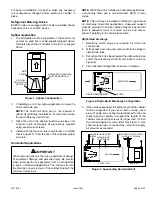

Excessive condensation may occur if the unit is installed

in a warm, humid place. When the unit is installed in an

unconditioned space, apply sealant around electrical

wires, refrigerant piping and condensate lines at the

point where they enter the cabinet.

Apply sealant on the inside of the cabinet at the

point where the electrical wires exit through the

conduit opening. This will also keep warm and moist

unconditioned air out of the air handler cabinet where

it will form condensate on the cooler control box and

electrical controls.

IMPORTANT

This unit is approved for installation clearance to

combustible material as stated on the unit rating

plate. Accessibility and service clearances must take

precedence over combustible material clearances.

The air handler must be installed so that free access is

allowed to the coil/filter compartment and blower/control

compartment.

IMPORTANT

•

During cooling operation, excessive sweating may

occur if the air handler is installed in a warm and

humid space.

•

If installed in an unconditioned space, sealant should

be applied around the electrical wires, refrigerant

tubing, and condensate lines where they enter the

cabinet.

•

Electrical wires should be sealed on the inside where

they exit the conduit opening. Sealant is required to

prevent air leakage into, and condensate from forming

inside of, the air handler, the control box, and on the

electrical controls.

Use of Air Handler During Construction

Units may be used for heating (heat pumps) or cooling of

buildings or structures under construction, if the following

conditions are met to ensure proper operation.

DO NOT USE THE UNIT FOR CONSTRUCTION HEAT

UNLESS ALL OF THE FOLLOWING CRITERIA ARE

MET:

•

A room thermostat must control the air handler. The

use of fixed jumpers is not allowed.

•

Air filter must be installed in the system and must be

maintained during construction.

•

Air filter must be replaced upon construction

completion.

•

The air handler evaporator coil, supply fan assembly

and duct system must be thoroughly cleaned following

final construction clean-up.

•

All air handler operating conditions must be verified

according to these installation instructions.

EQUIPMENT MAY EXPERIENCE PREMATURE

COMPONENT FAILURE AS A RESULT OF FAILURE TO

FOLLOW THE ABOVE INSTALLATION INSTRUCTIONS.

FAILURE TO FOLLOW THE ABOVE INSTALLATION

INSTRUCTIONS VOIDS THE MANUFACTURER’S

EQUIPMENT LIMITED WARRANTY. ALLIED AIR

DISCLAIMS ALL LIABILITY IN CONNECTION WITH

INSTALLER’S FAILURE TO FOLLOW THE ABOVE

INSTALLATION INSTRUCTIONS.

NOTWITHSTANDING THE FOREGOING, INSTALLER IS

RESPONSIBLE FOR CONFIRMING THAT THE USE OF

CONSTRUCTION HEAT OR COOLING IS CONSISTENT

WITH THE POLICIES AND CODES OF ALL REGULATING

ENTITIES. ALL SUCH POLICIES AND CODES MUST BE

ADHERED TO.

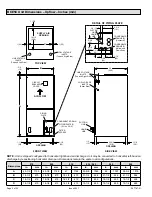

Installation Clearances

Non-Ducted Return Closet Installation

The air handler can be installed in a closet with a false

bottom to form a return air plenum. It may also be installed

with a return air plenum under the air handler.

Louvers or return air grilles are field-supplied. Local codes

may limit application of systems without a ducted return to

single-story buildings.

When a BCE5C

unit is installed in a closet with a louvered

return opening, the minimum open area for the louvers will

be:

•

320 square inches for -018 and -024 models;

•

360 square inches for -030 and -036 models;

•

450 square inches for -042 thru -060 models

If the free area is not known, assume a 25% free area for

wood or a 75% free area for metal louvers or grilles. Using

the louver dimensions and the 25% or 75% assumption,

determine if the open area meets the minimum open area

listed above.

If a return air plenum is used, the return air grille should be

immediately in front of the opening in the plenum to allow

for the free flow of return air. When not installed in front of

the opening, there must be adequate clearance around the

air handler to allow for the free flow of return air.

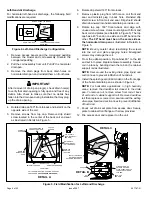

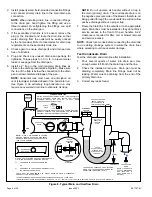

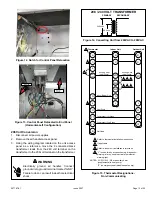

Installation

Each unit consists of a blower assembly, refrigerant coil,

and controls in an insulated galvanized steel factory-

finished enclosure. Knockouts are provided for electrical

wiring entrance.