Rockwell Automation Publication 843ES-IN001B-EN-P - February 2020

5

CIP Safety Encoder

5. Slide the encoder back onto the shaft until the flex mount rests

on the machine surface.

6. Attach the encoder with two M3 (or equivalent) screws. Screw

the stator coupling and the torque stop without preload on the

drive flange. Tighten the screws to 1 N•m [8.9 lb•in].

7. Tighten the clamping ring screw to 2.5 N•m (22.1 lb•in).

8. Align machine to its mechanical zero or home position.

Electrical Installation

Route the encoder cable free of any tension, so that no additional force

is applied to the encoder. Consider the minimum bending radius of the

connection cable.

Connectivity Considerations

Consider using the shortest length possible for both Ethernet and

power cables. Run Ethernet cables separate from power cables and run

the DC power cable away from AC power.

Verify that no other devices with high interference levels such as

frequency converters, solenoid valves, or contactors, are connected to

the same power supply as the encoder. Otherwise, use suitable voltage

filtering.

We recommend shielded twisted-pair cables for both Ethernet and

power connections. These cables help avoid disruptions of signals from

electrical noise and from mechanical vibration and shock that are

common in most industrial environments. When installing the

shielded cables, you must follow the recommended installation

guidelines to avoid ground loops. You must comply with the maximum

permissible connection cable length.

For shielded Ethernet cables, you must provide an equipotential

grounding network that overlays the existing electrical grounding and

bonding system for safety and fire. If you cannot provide an

equipotential ground and the second connection from the encoder is

going to a switch, install a patch panel to break the shield to the switch.

Switches typically connect jack shield directly to the ground lug, which

connects the shield directly to ground.

Diagnostics

After switching on the power supply, wait at least 10 seconds until the

encoder is ready for operation and interfaces are ready for

communication. The encoder communicates with the digital interface

after this period.

ATTENTION:

• Make sure that the operating voltage is switched on or off

simultaneously for the encoder and the downstream device.

• Electrostatic discharges at the contacts of the connector or at

the cable ends could damage or destroy the device. Take

appropriate precautionary measures.

• Use a PELV supply voltage source according to IEC 60204-1

complying with the proper operating voltage and the

maximum permissible output current.

IMPORTANT

To connect the encoder, refer to the corresponding operating

and safety instructions of the external drive system/encoder

evaluation system.

When assembling a mating connector, comply with the

instructions that are attached to the connector.

IMPORTANT

Verify that all required cable wires/connectors are connected

before commissioning. Insulate individually all unused ends

of the output signals to avoid short-circuits.

ATTENTION:

Before connecting or disconnecting the signal cable,

always disconnect the power supply and secure it against

switching on again.

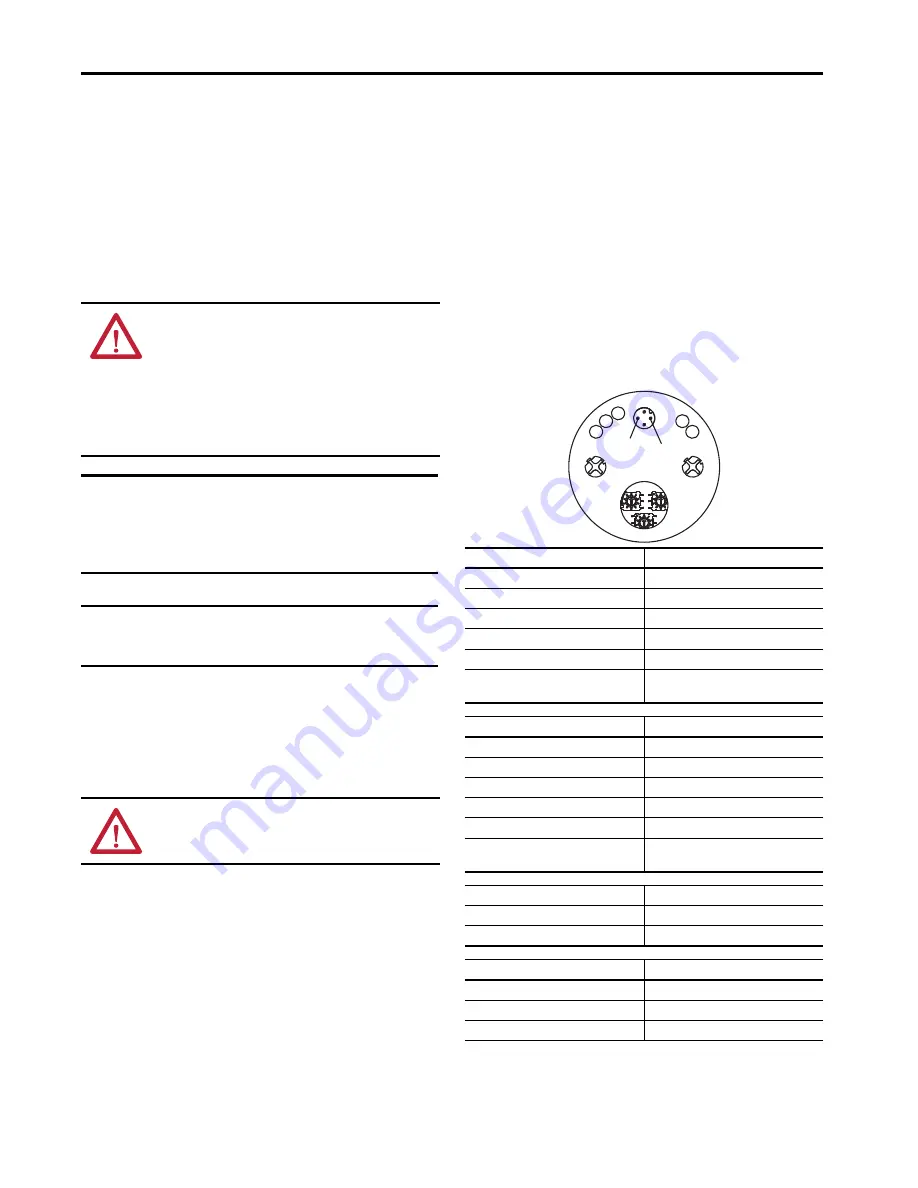

Module Status Indicator

Short Description

OFF

No power

Green flashing

Standby/idle

Green solid

Device operational

Red flashing

Minor fault

Red solid

Major fault

Green/red flashing

Self-test

Device not configured

Network Status Indicator

Short Description

OFF

No power/IP address

Green flashing

Not connected

Green solid

Connected

Red flashing

Minor fault

Red solid

Major fault

Green/red flashing

Self-test

Fast flashing during safety commissioning

Encoder Status Indicator

Short Description

Green solid

Power ON

OFF

No power

Link 1/Link 2 Status Indicator

(1)

(1)

The Ethernet link status indicators (Link 1 and Link 2) display the status of the physical connection on the

Ethernet interface.

Short Description

OFF

No link/power OFF

Green solid

Ethernet connection is established

Green flashing

Data transmission/port active

Net.

Encoder

Mod.

Link 1

GND

Port 1

x100

x10

x1

10…30V DC Link 2

Port 2