20

When the water temperature approaches the stop temperature of 80ºC, the sensor starts the cooker to perform a series of

cooling cycles or interrupts the operation of the cooker automatically by means of “ECO-STOP” to prevent the blocking of the

capillary temperature sensor described above.

- ELECTRICAL SAFETY

The cooker is protected against high current interferences by standard fuses located in the main switch on the back of the

cooker and on the control panel.

- FLUE GAS FAN

If the fan stops, the control panel is immediately blocking the pellets feed and the alarm signal is displayed.

- MOTOR WITH REDUCER

When the engine with the gearbox stops working, the cooker continues to operate until the flame goes out due to the lack of

oxygen and until the minimum cooling level is reached.

- TEMPORARY POWER OUTAGE

After a short power outage, the cooker automatically switches to cooling.

- NO IGNITION

When the flame does not develop during ignition stage, the cooker switches to alarm state.

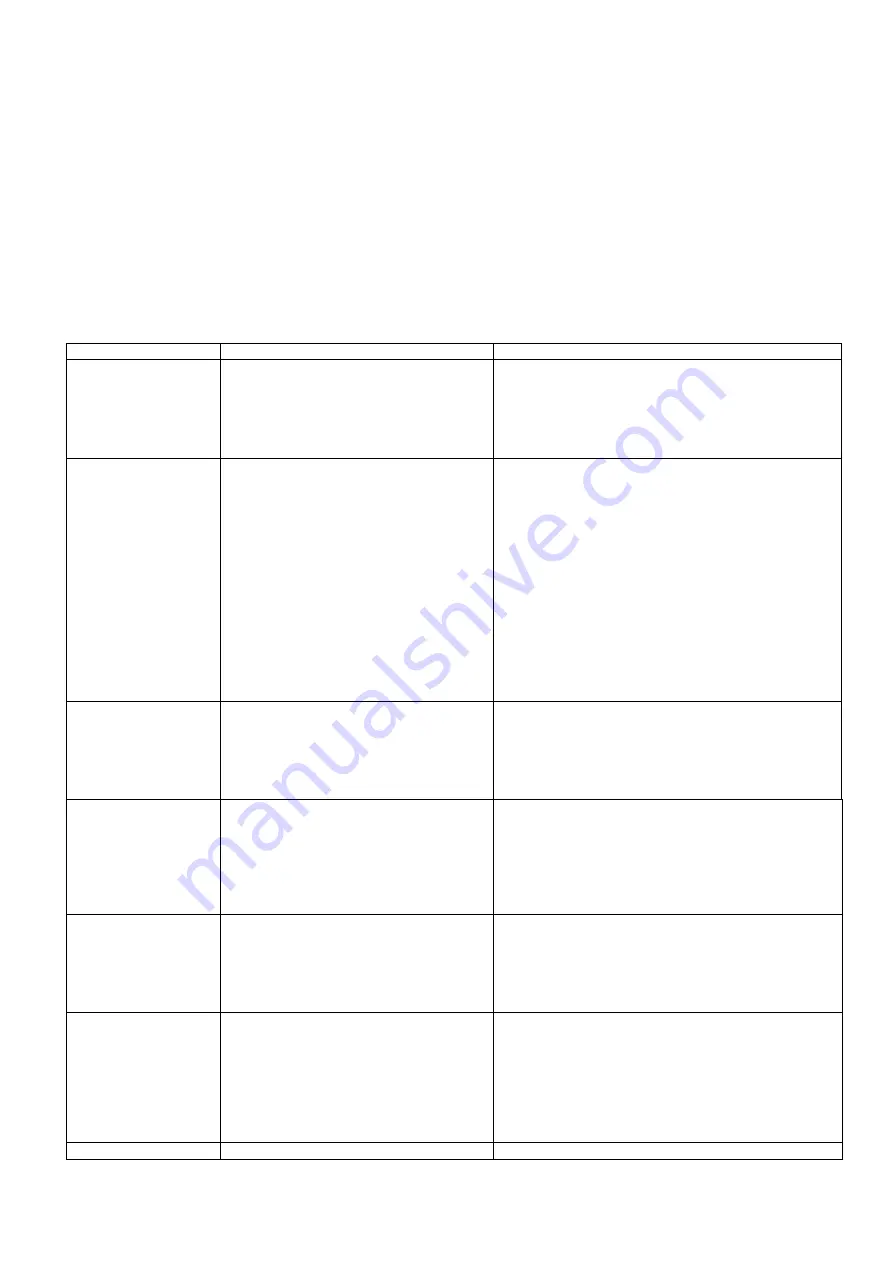

16.

FAULTS - CAUSES - SOLUTIONS

PROBLEMS

POSSIBLE CAUSES

SOLUTIONS

Pellets not

inserted into the

firebox.

1. The pellets storage is empty.

2. The infinite spiral is blocked.

3. The reducer of the infinite spiral is

defective.

4. The electronic card is defective.

1. Refill the storage

2. Empty the storage and unblock the spiral - auger

3. Replace the reducer

4. Replace the electronic card

The fire

extinguishes or the

cooker automatically

turns off.

1. The pellets storage is empty.

2. The combustion chamber is not

supplied with pellets.

3. Pellets temperature probe

intervention.

4. Doors are not completely closed or

gaskets are worn out.

5. Inadequate pellets.

6. Poor supply of pellets.

7. The combustion chamber is dirty.

8. The chimney is blocked.

9. Interference or malfunction on the

pressure switch.

10. The engine of the smoke aspirator

is damaged.

1. Fill the storage with pellets.

2. See the previous solution.

3. Allow the cooker to cool down completely and

turn it on again. If the problem persists, contact the

technical service.

4. Close the door or replace the gaskets with the

genuine gaskets.

5. Change the pellet type and select the type that is

approved by the manufacturer.

6. Check dosing and adjustment.

7. Clean the combustion chamber according to the

instructions in the manual.

8. Allow the smoke duct to be cleaned.

9. Replace the pressure switch.

10. Check the engine and possibly replace it.

The cooker works

for a few minutes and

then goes out.

1. Ignition stage did not end.

2. Temporary power outage.

3. Flue duct clogged.

4. Interference or fault in the

temperature probe.

5. Spark plug is damaged.

1. Repeat the ignition stage.

2. See the previous instruction.

3. Clean the flue duct.

4. Check or replace the probe.

5. Check or replace the spark plug.

Pellets are

deposited in the

combustion chamber.

The door glass is dirty

and the flame is weak.

1. Lack of combustion air.

2. Moist or inadequate pellets.

3. Engine of the flue suction system is

defective.

1. Clean the combustion chamber and ensure that

all openings are passable. Perform the standard

cleaning of the combustion chamber and flue duct.

Make sure the air supply is not blocked. Check the

condition of the gaskets on the door.

2. Change the type of pellets.

3. Check the engine and possibly replace it.

The engine of the

vacuum cleaner does

not work.

1. Cooker does not receive electricity.

2. Engine is damaged.

3. Control panel is defective.

4. Control panel does not work.

1. Check the power supply network and the melting

resistance safety.

2. Check the engine and condenser and possibly

replace.

3. Replace the electronic card.

4. Replace the control panel.

In automatic

mode, the cooker is

constantly running at

maximum capacity

1. Thermostat is programmed to the

maximum position

2. Ambient air thermostat always

measures cold air.

3. Probe that measures the

temperature is damaged.

4. Control panel is faulty or not

working.

1. Set the temperature of the thermostat again.

2. Change the position of the probe.

3. Check the probe and possibly replace it.

4. Check the control panel and possibly replace it.

Cooker does not

1. Lack of electricity

1. Make sure the plug is pressed and the main