3

For proper use of the cooker it is necessary to:

- use only fuel that complies with the manufacturer's instructions,

- always comply with the cooker maintenance schedule,

- clean the cooker daily (only when the cooker and ashes are cold),

- do not use the cooker in the event of a malfunction or some irregularities in operation, in case of unusual sounds and/or if

you suspect a malfunction,

- do not spray or spill water on the cooker, even when extinguishing the fire,

- do not turn off the cooker by pulling out the plug. Use a switch,

- do not lean on the cooker, because it may not be stable enough and COULD TURNOVER,

- do not use the cooker as a support or holder. Never leave the fuel storage cover open.

- do not touch the painted parts of the cooker while it is in operation,

- do not use wood or coal as a fuel, but only pellets with the following characteristics: diameter 6 mm, maximum length 30

mm, maximum moisture content 8-9%,

- do not use the cooker to incinerate the waste,

- always perform all operations with maximum security measures applied.

7.

INSTRUCTIONS FOR SAFE TURNING ON AND CLEANING T HE

COOKER

- Never use petrol, petroleum or any other flammable liquid to start fire in the cooker. Keep these types of fluids away from

the cooker while it is in operation,

- Never turn on the cooker if the glass is damaged. Do not hit the glass or door in order to prevent damage,

- Do not open the firebox door to clean the glass. Clean the glass only when the cooker is cold, using a cotton cloth or paper

towels (cloths) and a glass cleaning agent,

- Make sure that the cooker is well secured to prevent any movement,

- Make sure that the ashtray is inserted and completely closed so that it is correctly set on the front of the cooker,

- Make sure that the firebox door is well closed while the cooker is in operation,

- With the vacuum cleaner remove ash from the cooker only when the cooker is completely cold,

- Never use abrasive cleaners on the surface of the cooker.

7.1.

REGULAR CLEANING AND MAINTENANCE PERFORMED BY THE

USER OF THE COOKER

Regular cleaning and maintenance is a prerequisite for the proper and efficient operation of the cooker.

IMPORTANT: Clean the appliance only when the cooker and ashes are cold.

Using the ash vacuum cleaner can facilitate the cleaning of the cooker. The vacuum cleaner must have a filter that prevents

the ash and unburned pellets from being returned to the room where the cooker is located.

Before you start with regular maintenance, including cleaning, the following precautions should be taken:

- turn off the cooker from the power supply before you start doing any work,

- before starting any work, make sure that the cooker and ashes have cooled down,

- vacuum the ash from the combustion chamber every day,

- clean the firebox carefully every day (after each use) with the vacuum cleaner,

Always ensure that the cooker and ash are cold.

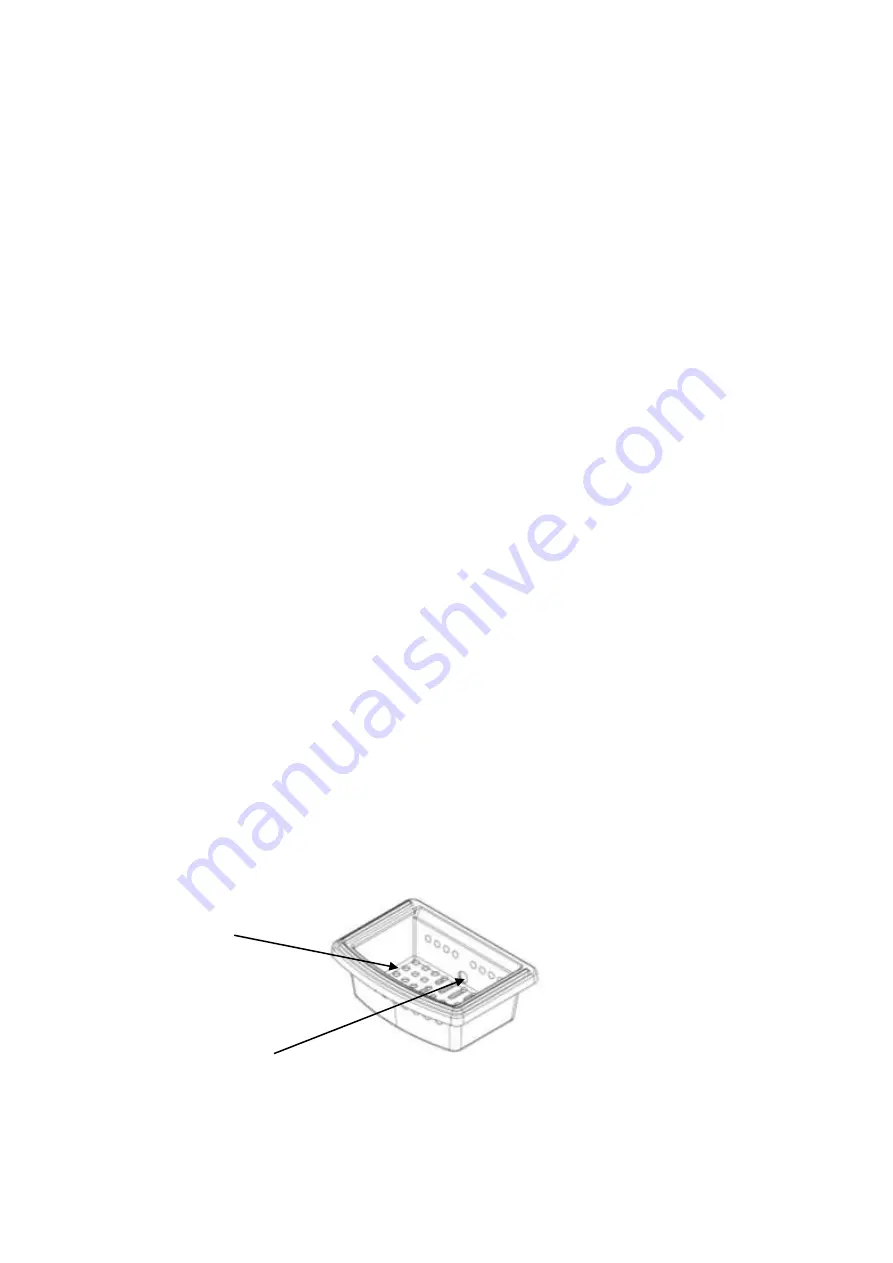

- Firebox (Figure 11) is a part of the cooker in which the pellets are burned. It is recommended to clean the firebox with the

vacuum cleaner after each use. Cleaning is done by taking the firebox out and cleaning it from ash, slag and unburned pellets.

After cleaning, return the firebox back and place it firmly in its place to ensure the safe operation of the cooker. The firebox must

be in a horizontal position, it must not be inclined! The gasket on the underside of the firebox must be in place and must not be

damaged.

If something is unclear to you, do not hesitate to call our authorized customer service for further information and

explanations. The manufacturer has no insight into the installation of the cooker and does not provide a warranty for the

installation and maintenance of the cooker.

The manufacturer does not assume any responsibility for damages caused by third parties.

Figure 11

- Ashtray (Figure 12) should be emptied every day before turning the cooker on, or more often, if necessary. The aim of this

cleaning is to allow the free flow of air for combustion.

Make sure the cooker and ash have cooled down.

The ashtray must be properly returned to its place. Never leave pellets that have not burnt in the firebox or ashtray.

2. Opening for introduction of

pellets ignition heater

1.

In order to ensure the

best operation of the

cooker, all openings

must be free of ash

(passable)