Page 31

4 - Distance between exhaust pipe terminations on mul

tiple furnaces must meet local codes.

FIGURE 40

NON-DIRECT VENT ROOF TERMINATION KIT

(15F75 or 44J41)

UNCONDITIONED

ATTIC SPACE

3” (76mm) OR

2” (51mm) PVC

PROVIDE SUPPORT

FOR EXHAUST LINES

12” (305mm)

ABOVE AVE.

SNOW

ACCUMULATION

SIZE TERMINATION

PIPE PER TABLE

10.

NOTE - Do not discharge exhaust gases directly into any chimney or vent stack. If ver

tical discharge through an existing unused chimney or stack is required, insert piping

inside chimney until the pipe open end is above top of chimney and terminate as illus

trated. In any exterior portion of chimney, the exhaust vent must be insulated.

FIGURE 41

3” - 8”

(76mm-

203mm)

3” - 8”

(76mm-

203mm)

STRAIGHT-CUT OR

ANGLE-CUT IN DIRECTION

OF ROOF SLOPE

SHOULDER OF FITTINGS

PROVIDE SUPPORT

OF PIPE ON TOP PLATE

EXTERIOR

PORTION OF

CHIMNEY

INSULATE

TO FORM

SEAL

SHEET

METAL TOP

PLATE

SIZE TERMINATION

PIPE PER TABLE 10.

95AF2DFV NON-DIRECT VENT APPLICATION

USING EXISTING CHIMNEY

Minimum 12” (305MM)

above chimney top

plate or average snow

accumulation

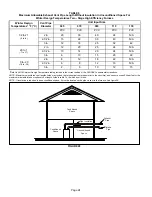

Condensate Piping

This unit is designed for either right‐ or left‐side exit of con

densate piping. Refer to figure 42 for condensate trap loca

tions.

NOTE

- If necessary the condensate trap may be installed

up to 5’ away from the furnace. Use PVC pipe to connect

trap to furnace condensate outlet. Piping from furnace

must slope down a minimum of 1/4” per ft. toward trap.

FIGURE 42

CONDENSATE TRAP AND PLUG LOCATIONS

Trap

(same on

right side)

Plug

(same on left

side)

1-1/2 in.

1 - Determine which side condensate piping will exit the

unit, location of trap, field-provided fittings and length

of PVC pipe required to reach available drain.

2 - Use a large flat head screw driver or a 1/2” drive socket

extension and remove plug (figure 42) from the cold

end header box at the appropriate location on the side

of the unit. Install provided 3/4 NPT street elbow fitting

into cold end header box. Use Teflon tape or appropri

ate pipe dope.

3 - Install the cap over the clean out opening at the base

of the trap. Secure with clamp. See figure 47.

4 - Install drain trap using appropriate PVC fittings, glue

all joints. Glue the provided drain trap as shown in fig

ure 47. Route the condensate line to an open drain.

5 - Figure 45 shows the furnace and evaporator coil using

a separate drain. If necessary, the condensate line

from the furnace and evaporator coil can drain togeth

er. See figure. The field provided vent must be a mini

mum 1” to a maximum 2” length above the condensate

drain outlet connection.

NOTE

- Appropriately sized tubing and barbed fitting

may be used for condensate drain. Attach to the drain

on the trap using a hose clamp. See figure 43.