26

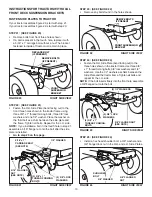

RAISING AND LOWERING

• To raise, push down on the lift handle until the snow

thrower locks in the raised transport position.

• To lower, push down slightly on the lift handle and pull

the trigger. With the trigger pulled, slowly lower the

snow thrower until it reaches the ground.

CUSTOMER RESPONSIBILITIES

• Read and follow the maintenance schedule and the maintenance procedures listed in this section.

Service Dates

Check for loose fasteners

X

Check scraper and shoes for wear

X

X

Cleaning

X

Lubrication Section

X

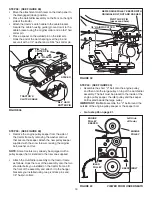

MAINTENANCE SCHEDULE

Fill in dates as you

complete regular service.

Bef

ore each use

After each use

Ev

ery season

Bef

ore stor

age

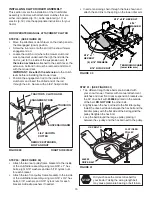

LUBRICATION

•

Oil all pivot points on the snow thrower.

• Oil the pivot points of the two idler arms on the clutch/

idler assembly.

• Apply penetrating oil to the control cables of the

discharge chute.

• Apply a good grade of spray lubricant to the trigger

assembly and the chute tilt control assembly.

CAUTION

:

Do not operate the snow

thrower without the rear weight attached

to the tractor to provide extra traction and

stability.

MAINTENANCE

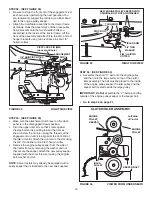

CHECK SCRAPER AND SHOES FOR WEAR

(Refer to figures 59 and 60 on page 27)

• The scraper plate and skid shoes on the bottom of the

snow thrower are subject to wear. To prevent damage

to the spiral auger housing, replace plate and shoes

before wear is excessive.

REMOVING SNOW

Snow removal conditions vary greatly from light fluffy

snowfall to wet heavy snow. Operating instructions must

be flexible to fit the conditions encountered. The operator

must adapt the lawn tractor and snow thrower to depth of

snow, wind direction, temperature and surface conditions.

• Before beginning operation, thoroughly inspect the

area of operation and remove all door mats, sleds,

boards, wires and other foreign objects.

• The spiral auger speed is directly related to engine

speed. For maximum snow removal and discharge,

maintain high engine r.p.m. (full throttle). It is advisable

to operate the lawn tractor at a slow ground speed

(1st gear) for safe and efficient snow removal.

• In deep, drifted or banked snow it will be necessary to

use full throttle and a slow ground speed (1st gear).

Drive forward into the snow, depress the tractor's

clutch-brake pedal and allow the spiral auger to clear

the snow. Repeat this method until a path is cleared.

On the second pass, overlap the first enough to allow

the snow thrower to handle the snow without repeated

stopping and starting of forward motion.

• In extremely deep snow, raise the snow thrower from

the ground to remove the top layer and drive forward

only until the tractors front tires reach the uncleared

bottom layer of snow. Depress the tractor's clutch-

brake pedal and allow the spiral auger to clear the

snow. Reverse the tractor and lower the snow thrower

to the ground. Drive the tractor forward until the snow

again becomes too deep. Repeating this process into

and out of drifts will eventually clear even the deepest

of snow piles.

• If the snow thrower becomes clogged with snow or

jammed with a foreign object, disengage the snow

thrower immediately and shut off the tractor engine.

Unclog the snow thrower before resuming operation.

OPERATING TIPS

• Discharge snow down wind whenever possible.

• To help prevent snow from sticking to the snow thrower,

allow the snow thrower to reach outdoor temperature

before using it. A light coat of wax may also be applied

to the inside surface of the snow thrower housing and

discharge chute.

• Use tire chains to improve traction.

• Use rear wheel weights to improve traction.

• Before the first snowfall, remove all stones, sticks and

other objects which could become hidden by the snow.

Permanent obstacles should be marked for visibility.

• Overlap each pass slightly to assure complete snow

removal.

DANGER

:

Shut off engine and

disengage snow thrower before

unclogging discharge chute. Unclog using

a wooden stick, not your hands.

Содержание LST42E

Страница 29: ...29 NOTES...