Page 23

REF #

PART #

PART NAME

SPECIFICATIONS

QTY PER UNIT

1

310-632

Beam incl. End Plate

22T

1

2

320-930

Log Tray Frame FR ( BL)

2

3

320-931

Log Tray Frame FL (BR)

2

4

320-938

Log Tray Plate

2

5

710-518

Hex Head Bolt

Zinc, M10*30

12

6

750-525

Flat Washer

M10

24

7

720-120

Lock Nut

M10

12

8

320-925

Log Dislodger

2

9

710-518

Hex Head Bolt

Zinc, M10*30

4

10

750-525

Flat Washer

M10

8

11

720-120

Lock Nut

M10

4

12.1

320-929

Log Dislodger Support R

1

12.2

320-928

Log Dislodger Support L

1

13

710-511

Hex Head Bolt

Zinc, M12*45

4

14

750-621

Flat Washer

M12

8

15

720-536

Lock Nut

M12

4

16

710-511

Hex Head Bolt

Zinc, M12*45

4

17

750-621

Flat Washer

M12

8

18

720-536

Lock Nut

M12

4

19

530-465

Cylinder

4”

1

20

760-112

Pin

Black Oxide, Ø20*72

1

21

750-423

Flat Washer

M20

2

22

760-734

Split Pin

Zinc, Ø4*35

2

23

760-118

Pin

Black Oxide, Ø16*69

1

24

750-642

Flat Washer

Zinc, M16

2

25

760-734

Split Pin

Zinc, Ø4*35

2

26

530-427

Splitting Wedge w/ Guides

1

27

560-422

Hydraulic Hose for A-Capacity

1/2”*572

1

28

560-377

Protective Spring

Ø27*540*Ø1.5

1

29

510-339

Hydraulic Adaptor for A-Capacity

1

30

510-467

Hydraulic Adapter for B-Capacity

1

31

510-334

Hydraulic Adapter for Oil Return Hose

1

32

560-478

Oil Return Hose

1/2”*2540

1

33

510-455

Hydraulic Adapter for Oil Suction Hose

1

34

560-478

Oil Suction Hose

1/2”*2540

1

35

520-799

Hydraulic Valve

1

36

520-452

Control Handle

Ø16*210

1

37

350-226

Valve Cover

1

38

710-637

Hex Head Bolt

Zinc, M8*20

4

39

750-638

Flat Washer

M8

4

40

750-834

Spring Washer

M8

4

41

320-623

U-shape mounting bracket bar

1

42

710-573

Hex Head Bolt

Zinc, M12*60

2

43

750-834

Spring Washer

M12

2

44

750-621

Flat Washer

M12

2

45

720-359

Nut

M12

2

46

320-839

Frame Top

1

47

760-253

Clevis Pin

Zinc, Ø16*110

1

48

760-688

Spring Clip

Ø2.5

1

49

320-843

Horizontal Beam Lock

1

50

710-535

Hex Head Bolt

Zinc, M10*80

2

51

750-525

Flat Washer

M10

4

52

720-120

Lock Nut

M10

2

53

320-874

Frame Leg

4

54

710-535

Hex Head Nut

Zinc, M10*80

8

55

750-401

Spring Washer

M10

8

56

750-525

Flat Washer

M10

8

57

720-124

Nut

M10

8

Page 26

Содержание BE-LS22TL3PT

Страница 2: ......

Страница 6: ......

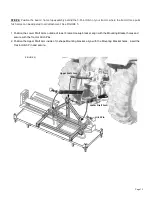

Страница 29: ...Page 22 EXPLODED DIAGRAM PARTS LIST Page 25...

Страница 32: ...Page 25 Page 28...

Страница 34: ...Page 27...

Страница 35: ...Page 28...

Страница 36: ...Page 29 Phone 1 877 588 3311 Fax 1 800 665 7334 WWW BRABEREQ COM...