46

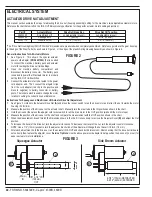

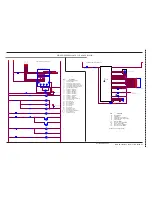

- FORM NO. 56043096 - Captor

™

4300B, 4800B

ELECTRICAL SYSTEM

WIRING DIAGRAM sheet 1 of 3 (after SN 1808248)

B- INPUT

CONTROL

BOX

ASSEMBLY

A1

MODE 1

FAULT 1

BRAKE DRIVER

REVERSE SIGNAL

BRUSH CURRENT SENSE

-12 VDC

BROOM CURRENT SENSE

(OPTIONAL)

TO SPEED CONTROLLER

(OPTIONAL)

140 DEG. F

(+ TO RED TO EXTEND)

(+ TO RED TO EXTEND)

A2

SWITCH/DISPLAY

PANEL

ASSEMBLY

(+ TO RED TO EXTEND)

J3-2 (SCL-H)

J3-3 (SCL-L)

J3-4 (SDA-H)

J3-5 (SDA-L)

J3-6 (B+)

J3-1 (B-)

J2-7

J2-18

J2-8

J2-19

J2-10

J2-31

J1-21

J2-11

J2-24

J1-1

J2-35

J1-4

J1-15

J1-18

J1-16

J1-14

J1-20

J1-8

J1-7

J1-19

J1-17

J1-6

J1-5

J1-3

J1-9

J2-34

J2-33

J1-10

J1-2

J2-20

J1-34

J1-32

J1-30

J1-28

J1-26

J1-11

J1-12

J2-15

J2-3

J1-24

J1-13

J1-35

J1-23

J2-2

J2-6

J2-5

J2-16

J2-13

J2-4

J4-14

J2-29

J2-1

J2-26

J2-25

J2-21

J2-22

TO SPEED CONTROLLER

J2-12

J2-23

LAMP GROUND

AXP SYSTEM

J2-17

TO STEERING SYSTEM

E

J2-11 SIGNAL INPUT

(SOLENOID)

J1-2 B+

SOLUTION J2-9

LEVEL

J1-4 SOLUTION

PUMP

B- J1-1

CHEMICAL J2-2

PUMP1 +

CHEMICAL J2-4

PUMP1 -

CHEMICAL J2-6

PUMP1 +

CHEMICAL J2-8

PUMP1 -

J2-10 SOLUTION

FLOW RATE

J2-14 SENSE

INPUT

J2-13 +5V

J2-12 B-

CHEMICAL SENSING

BOARD

J1-4

J1-1

J1-2

F

ORN/RED

GRA

RED/WHT

BRN

BLU/BLK

BLK

ORN/BLU

VIO

VIO

RED

RED

VIO

VIO

GRN/BRN

VIO/BRN

BRN/YEL

BLU

BRN/BLK

GRA/RED

BLU/WHT

VIO

VIO

VIO

VIO

VIO

YEL/BLU

WHT/VIO

VIO

VIO

GRN/BLK

VIO

RED/GRA

BLU/RED

YEL/RED

BRN/GRN

VIO

VIO

VIO

VIO

RED

VIO

VIO

VIO

VIO

YEL/BLK

BLK/RED

VIO

GRN/GRA

VIO

VIO

ORN

RED

GRN

BLK/ORN

YEL/BRN

YEL/BLK

YEL/GRN

BLK

BLK

BLK

BLK

BLK

BLK

BLK

BLK

BLK

GRN/BLU

BRN/BLU

BLK

WHT/BRN

RED/ORN

GRN/VIO

RED/GRN

BLU/BRN

GRN/ORN

YEL/GRA

WHT/GRN

GRA/VIO

BLK

GRA/WHT

YEL/VIO

BLK

RED/BLK

GRA/YEL

BLK

BLK

WHT/GRA

YEL/WHT

ORN/BLK

BLK

BLK

BLK

BLK/WHT

BLK

BLK

ORN/BRN

BLU/ORN

BLK/GRA

VIO

GRN/BLK

YEL/BRN

RED

ORN

BLU/GRN

BLU/GRN

BLK/WHT

GRN/BLU

BRN/BLU

WHT/BRN

BLK

BLU/ORN

ORN/BRN

BLU/GRN

GRA/BRN

GRA/BRN

BLK/GRA

GRA/BRN

BLK

BLU/ORN

BLU/GRN

BLK

YEL/GRN

BLK

VIO/YEL

VIO/YEL

VIO/YEL

ORN

PINK

GRA/ORN

TAN

ORN

GRA/ORN

GRN

YEL

VIO

BLU

B-

G

R

A

O

R

N

/R

E

D

B

R

N

B

LU

/B

LK

O

R

N

/B

LU

R

E

D

/W

H

T

B+

GRN

ORN

GRA/ORN

M

M14

MOTOR, SHAKER

BLK

RED

S14

SWITCH, WAND

(OPTIONAL)

1

2

L6A

VALVE, HOPPER LOWER

1

2

K8

CONTACTOR, SIDE BROOM

R2

FLOW POSITION SENSOR

1

2

3

C

C

K10

CONTACTOR, AUX.

BT1

BATTERY, 36 Vdc

+

-

H4

HEAD LIGHT, LEFT

1

2

H6

LAMP, TAIL

A

B

F2

CIRCUIT BREAKER, 5 AMP

1

2

K6

CONTACTOR, DUST CONTROL MOTOR

S13

SWITCH, BATTERY INTERLOCK

1

2

H10

LAMP, BROOM OVERLOAD

1

2

S5

SWITCH, SOLUTION EMPTY

1

2

K9

CONTACTOR, STEERING

M

M19

PUMP 2, CHEMICAL

-

+

M

M18

PUMP 1, CHEMICAL

-

+

K1

CONTACTOR, LEFT BRUSH MOTOR

S3

SWITCH, HOPPER INTERLOCK

1

2

F1

CIRCUIT BREAKER, 25 A.

1

2

S2

SWITCH, RETRACT LIMIT

WHT

GRN

D

D

S9

SWITCH, SEAT

2

1

L4

VALVE, DUMP DOOR OPEN

1

2

S8

SWITCH, MAIN BROOM

1

2

A

A

K12

RELAY, SAFETY

1

2

H7

LAMP, FLASHING

1

2

M

M17

PUMP, SOLUTION

-

+

K3

CONTACTOR, RIGHT BRUSH MOTOR

M

M11

MOTOR, BRUSH ACTUATOR

YEL

RED

L5

VALVE, DUMP DOOR CLOSE

1

2

X1

+ -

H9

LAMP, TROUBLE

1

2

L6

VALVE, HOPPER RAISE

1

2

M

M13

MOTOR, SIDE BROOM ACTUATOR

BLK

WHT

K10

CONTACTOR, AUX.

1

2

K7

CONTACTOR, VACUUM MOTOR

S6

SWITCH, DUST CONTROL FILTER

1

2

S11

SWITCH, KEY

B1

3

S7

SWITCH, HYDRAULIC FILTER

1

2

H1

BACKUP ALARM

+

-

S15

SWITCH, EMERGENCY STOP

1

2

H2

HORN

1

2

F6

CIRCUIT BREAKER, 10 A.

1

2

B

B

H8

LAMP, CURB

1

2

M

M12

MOTOR, SQUEEGEE ACTUATOR

BLK

WHT

F10

FUSE, 400 A.

1

2

K4

CONTACTOR, BROOM MOTOR

H5

LAMP, TAIL

A

B

t

o

S10

SWITCH, HOPPER FIRE.

1

2

3

E

E

F3

CIRCUIT BREAKER, 20 A

1

2

S1

SWITCH, EXTEND LIMIT

RED

BLK

X2

+ -

K11

CONTACTOR, HYD. PUMP MOTOR

F

F

L1

VALVE, SOLUTION

1

2

H3

HEAD LIGHT, RIGHT

1

2

S4

SWITCH, RECOVERY FULL

1

2

K2

CONTACTOR, CENTER BRUSH MOTOR

56303540 Rev. F Sheet 1 of 3

Revised diagram 6/12

Item

Description

A1

Control Box Assembly

A2

Switch/Display Panel Assembly

BT1

Battery 36Vdc

F1

Circuit Breaker, 25 Amp (Auxiliary Circuit 1)

F2

Circuit Breaker, 5 Amp (Auxiliary Circuit 2)

F3

Circuit Breaker, 20 Amp (Auxiliary Circuit 3)

F6

Circuit Breaker, 10A

(AXP)

F10

Fuse, 400 Amp (Main)

H1

Backup Alarm (optional)

H2 Horn

H3

Headlight, Right

H4

Headlight, Left

H5

Lamp, Tail

H6

Lamp, Tail

H7

Lamp, Flashing (optional)

H8

Lamp, Curb (optional)

H9

Lamp, Trouble (optional)

H10

Lamp, Broom Overload

K1

Contactor, Left Brush Motor

K2

Contactor, Center Brush Motor

K3

Contactor, Right Brush Motor

K4

Contactor, Broom Motor

K6

Contactor, Dust Control Motor

K7

Contactor, Vacuum Motor

K8

Contactor, Side Broom

K9

Contactor, Steering

K10

Contactor, Auxiliary

K11

Contactor, Hydraulic Pump Motor

L1

Valve, Solution

L2

Valve, Solution

L4

Valve, Dump Door Open

L5

Valve, Dump Door Close

L6

Valve, Hopper Raise

L6A

Valve, Hopper Lower

M11

Motor, Brush Actuator

M12

Motor, Squeegee Actuator

M13

Motor, Side Broom Actuator

M14

Motor, Shaker

M17

Pump, 36VDC

(AXP)

R2

Flow Position Sensor

(AXP)

S1

Switch, Extend Limit

S2

Switch, Retract Limit

S3

Switch, Hopper Interlock

S4

Switch, Recovery Full

S5

Switch, Solution Empty

S6

Switch, Dust Control Filter (optional)

S7

Switch, Hydraulic Filter

S8

Switch, Main Broom

S9

Switch, Seat

S10

Switch, Hopper Fire (optional)

S11

Switch, Key

S12

Switch, Wand (optional)

S13

Switch, Battery Interlock

Содержание 56303000

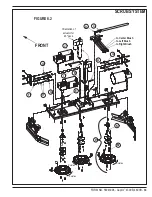

Страница 17: ...FORM NO 56043096 Captor 4300B 4800B 15 FRONT WHEEL SYSTEM FIGURE 3 1...

Страница 20: ...18 FORM NO 56043096 Captor 4300B 4800B HYDRAULIC SYSTEM FIGURE 4 3...

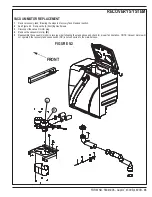

Страница 33: ...FORM NO 56043096 Captor 4300B 4800B 31 SOLUTION SYSTEM FIGURE 7 1...

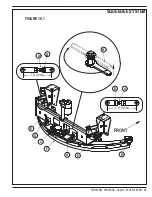

Страница 39: ...FORM NO 56043096 Captor 4300B 4800B 37 SQUEEGEE SYSTEM FIGURE 10 1...

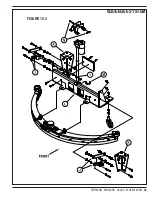

Страница 41: ...FORM NO 56043096 Captor 4300B 4800B 39 SQUEEGEE SYSTEM FIGURE 10 2...

Страница 45: ...FORM NO 56043096 Captor 4300B 4800B 43 WIRING SCHEMATIC before SN 1767238 ELECTRICAL SYSTEM...

Страница 50: ......