Mounting and installation

18

Thermal Mass Flowmeter FMT400-VTS, FMT400-VTCS (Sensyflow VT-S/VT-CS)

42/14-36 EN

4.7

Integrated hot tap fitting for FMT400-VTS (Sensyflow VT-S)

WARNING

Safety instructions

When dismounting, with more than 1.1 bar absolute pressure, or with high temperatures or health-

hazardous gases in the pipe, the use of the exchange tool is recommended and obligatory for safety

reasons.

Non-observance may lead to severe injuries of persons.

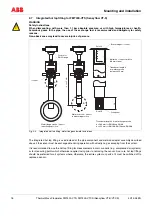

Fig. 4-4

Integrated hot tap fitting, wafer flange and weld-in versions

The integrated hot tap fitting is used instead of the pipe component and weld-on adapter assembly described

above if the sensor must be exchangeable during operation with virtually no gas escaping from the system.

It is recommended to use the hot tap fitting for measurements in main conduits (e.g. compressed air systems)

or for measuring points which otherwise require rinsing prior to removing the sensor. As a rule, hot tap fittings

should be preferred for all systems where, otherwise, the entire system or parts of it must be switched off to

replace a sensor.

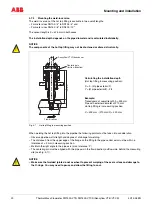

!

h = 425 mm

Detail B

50

50

A

B

Hub strok

e / mm

20

10

30

40

0 - CLOSE - ZU

50 - OPEN - MESSEN

Detail A

Transducer length h

for weld-in version

is always 425 mm

Wafer flange version – sensor

in exchange position

Weld-in version – sensor

in measuring position

Covers for

DN 25 flange

Indication of sensor position

(50 mm stroke)

O-ring seal

Bottom edge of lock nut

lock nut

Transducer length h for wafer flange version

h = 263 mm for DN 50 and DN 80

h = 425 mm for DN 100, DN 150 and DN 200