Operation Manual / Power2 650-M / Low-pressure stage

1 Introduction / 1.5 Layout and function of the low-pressure stage

© Copyright 2022 ABB. All rights reserved.

HZTL4065_EN

Rev.E

March 2022

Mode of operation of the low-pressure stage (Power2 LP)

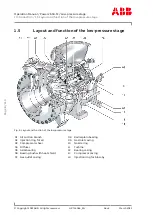

Fig. 3: Function of the low-pressure stage

Power2

Two-stage turbocharging

21

HP compressor

Power2 LP

Low-pressure stage

22

HP turbine

Power2 HP High-pressure stage

23*

Gas piping (bellows)

A

Exhaust gas inlet from internal combus-

tion engine

24

LP turbine

B

Exhaust gas outlet

25

LP compressor

C

Air or air/gas mixture inlet

26

Intercooler

D

Air or air/gas mixture outlet and supply

to the charge air cooler

- - -

Not included in the Turbo Systems

scope of delivery

*) If present

The low-pressure stage (Power2 LP) is a turbomachine and its main components are a tur-

bine and a compressor. These components are installed on a common shaft and form the ro-

tor.

In the low-pressure stage (Power2 LP) shown in the illustration

tion of the low-pressure stage

, the exhaust gas coming from the high-pressure

stage (Power2 HP) flows through the gas inlet casing (09) and the nozzle ring (10) and

reaches the turbine (11). The LP turbine uses the energy contained in the exhaust gas to

drive the rotor. The exhaust gases then reach the atmosphere through the gas outlet cas-

ing (07) and the exhaust gas pipe connected to it.

The rotor runs in two radial plain bearings (08). These are located between the compressor

and turbine and are guided in the bearing bush (06) and axial bearing (05). The plain bear-

ings are connected to a central lubricating oil duct which is normally supplied by the lubric-

ating oil circuit of the engine. The oil outlet lies at the deepest point of the bearing cas-

ing (12).

The LP compressor wheel (03) connected to the shaft sucks in fresh air or an air/gas mixture

through the filter silencer or the air suction branch (01). The air is compressed in the LP com-

pressor and the downstream diffuser (04). The compressed air is passed on to the inter-

cooler (26) via the compressor casing (13). The air is cooled in the intercooler (26) and sub-

sequently supplied to the HP compressor (21).

Using the injection ring (02), an air flow can be supplied upstream of the LP compressor

stage.

The blowby air can be supplied upstream of the LP compressor stage via the injection

ring (14).

Page

9

/

119