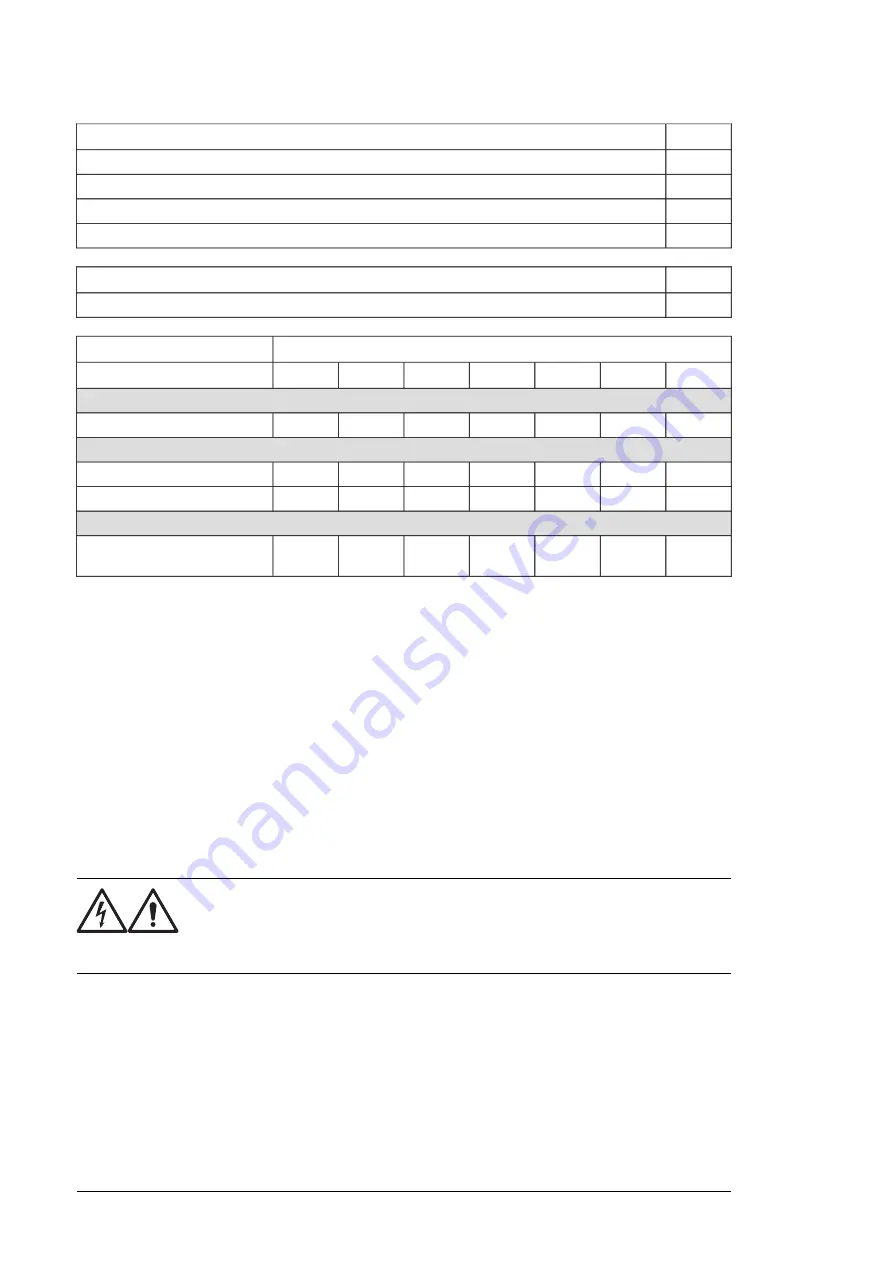

Recommended annual actions by the user

I

Tightness of terminals

I

Dustiness, corrosion and temperature

I

Cooling liquid pipe connections

P

Coolant antifreeze concentration

Recommended every 2nd year actions by the user

P

Inspection of coolant quality

Years from start-up

21

18

15

12

9

6

3

Coolant

R

R

R

Coolant draining and refill

Cabinet fans and fan control board

R

R

Cooling fans 230 VAC 50/60Hz

R

R

R

Cooling fans 115 VAC 50/60Hz

Common

R

BSFC Cabinet side charging

control board

Note:

• Maintenance and component replacement intervals are based on the assumption that

the equipment is operated within the specified ratings and ambient conditions. ABB

recommends annual drive inspections to ensure the highest reliability and optimum

performance.

• Long term operation near the specified maximum ratings or ambient conditions may

require shorter maintenance intervals for certain components. Consult your local ABB

Service representative for additional maintenance recommendations.

Cabinet

■

Cleaning the exterior of the drive

WARNING!

Obey the safety instructions of the drive. If you ignore them, injury or death,

or damage to the equipment can occur. If you are not a qualified electrical

professional, do not do installation or maintenance work.

1. Stop the drive and do the steps in section

Electrical safety precautions (page 27)

before

you start the work.

2. Clean the exterior of the drive. Use:

• vacuum cleaner with an antistatic hose and nozzle

• soft brush

• dry or damp (not wet) cleaning cloth. Moisten with clean water, or mild detergent

(pH 5-9 for metal, pH 5-7 for plastic).

46 Maintenance

Содержание ACS880-7107LC DC

Страница 1: ... ABB INDUSTRIAL DRIVES ACS880 7107LC DC feeder unit Hardware manual ...

Страница 2: ......

Страница 4: ......

Страница 8: ...8 ...

Страница 12: ...12 ...

Страница 22: ...22 ...

Страница 36: ...36 ...

Страница 40: ...40 ...

Страница 44: ...44 ...

Страница 50: ...50 ...

Страница 52: ...52 ...

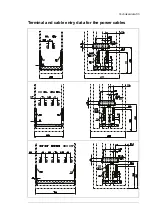

Страница 55: ...Terminal and cable entry data for the power cables Technical data 55 ...