63

Downloading a program and setting PLC in run mode

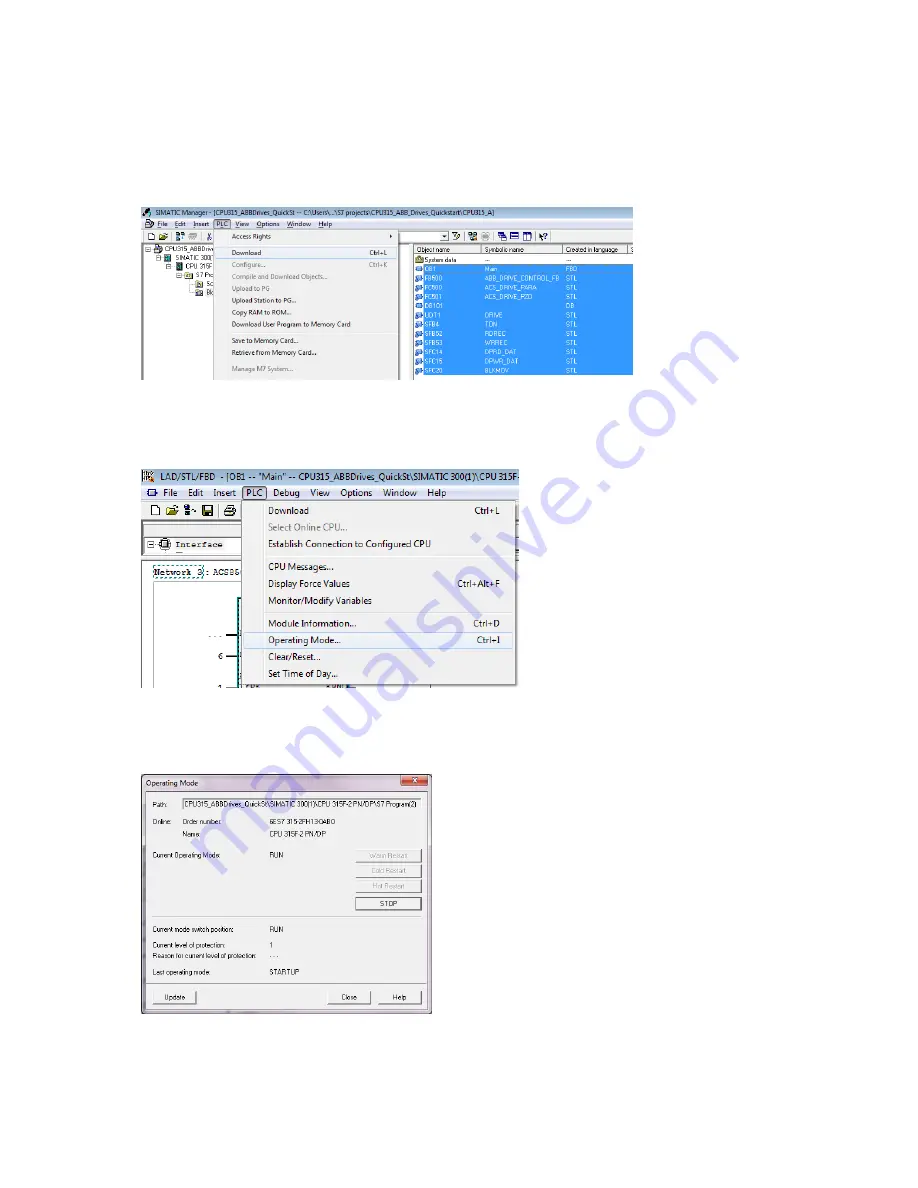

1. Open the block view in SIMATIC Manager.

2. Select all blocks and choose

Download

from the

PLC

menu.

Figure 36 Downloading PLC

3. Set the physical dip switch of the PLC in position

RUN

.

4. In the main menu, navigate to

PLC

→

Operating Mode.

Figure 37 Operating mode

5. In the

Operating Mode

dialog,

check that

Current Operating Mode

is

RUN

, if not then choose

and click preferred restart mode.

Figure 38 Current operating mode

Содержание ACS355 series

Страница 1: ...Quick start up guide ABB Drives function blocks for Siemens PLC s...

Страница 76: ...A new subnet and IP protocol is added Figure 56 IP added...

Страница 84: ...9 Click to download the configuration to PLC Figure 73 Download to device...

Страница 139: ...139 Contact us www abb com drives www abb com drivespartners 3AXD50000037864 Rev B EN 2018 02 07...