Fault tracing

291

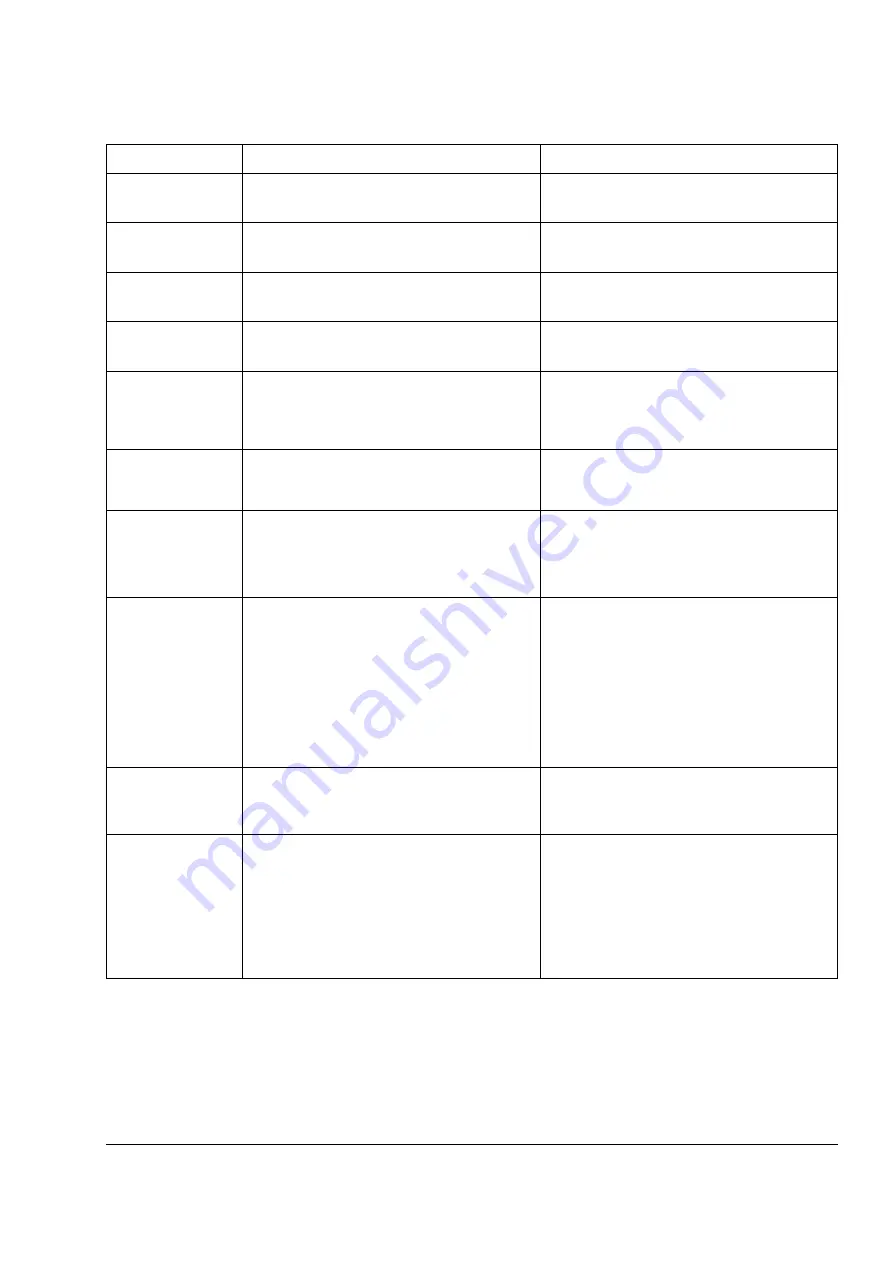

FLWR1 COM FLT

(FFBA)

Follower 1 Communication error .

Check CH2 communication, communication

settings.

FLWR2 COM FLT

(FFBB)

Follower 2 Communication error .

Check CH2 communication, communication

meetings.

FLWR3 COM FLT

(FFBC)

Follower 3 Communication error .

Check CH2 communication, communication

meetings.

FLWR4 COM FLT

(FFBD)

Follower 4 Communication error .

Check CH2 communication, communication

meetings.

GD DISABLED X

AGPS power supply of parallel connected R8i

inverter module has been switched off during

run. X (1...12) refers to inverter module

number.

Check Safe Torque Off circuit.

Replace AGPS board of R8i inverter module.

ID RUN FAIL

(FF84)

Motor ID run is not completed successfully.

Check maximum speed (parameter

should be at least 80% of motor nominal speed

(parameter

).

IN CHOKE TEMP

(FF81)

3.17 FW 5 bit 5

Excessive input choke temperature

Stop drive. Let it cool down.

Check ambient temperature.

Check that fan rotates in correct direction and

air flows freely.

INT CONFIG

(5410)

03.17 FW 5 bit 10

Number of inverter modules is not equal to

original number of inverters.

Check status of inverters. See signal

.

Check fibre optic cables between APBU and

inverter modules.

If Reduced run function is used, remove

faulted inverter module from main circuit and

write number of remaining inverter modules

into parameter

INT CONFIG USER.

Reset drive.

INV DISABLED

03.17 FW 5 bit 7

(3200)

Optional DC switch has opened while unit was

running or Start command was given.

Close DC switch.

Check AFSC-0x Fuse Switch Controller unit.

INV LIMIT

(FFBF)

3.33 CraneFW bit 5

The fault is generated when the drive has hit

TORQUE INVERTER CURRENT LIMIT or IPP

OVERTEMP ALM is active and a period of 200

ms has elapsed. The fault condition is only

checked when the generating power is more

than 10% of motor nominal power and the

speed is greater than 5% of the maximum

speed.

Check the Speed controller torque settings.

Check torque, speed, power limit settings.

FAULT

CAUSE

WHAT TO DO

Содержание ACS 800 Series

Страница 1: ...ACS800 Firmware Manual Crane Control Program N697 ...

Страница 4: ......

Страница 26: ...Start up and control through the I O interface 26 ...

Страница 36: ...Quick start up guide 36 ...

Страница 52: ...Control panel 52 ...

Страница 105: ...Program features 105 Figure Control diagram for Shaft synchronisation executed in 20 ms ...

Страница 126: ...Program features 126 The figures below show speed limits according to different load conditions ...

Страница 128: ...Program features 128 ...

Страница 150: ...Application macros control location EXT1 EXT2 150 ...

Страница 228: ...Actual signals and parameters 228 ...

Страница 299: ...Adaptive Programming examples for crane control 299 ...

Страница 305: ...Adaptive Programming examples for crane control 305 ...

Страница 312: ...Adaptive Programming examples for crane control 312 The following figures show the previous example enlarged ...

Страница 314: ...Adaptive Programming examples for crane control 314 The following figures show the previous example enlarged ...

Страница 318: ...Analogue Extension Module 318 ...

Страница 332: ...Additional data actual signals and parameters 332 ...

Страница 333: ...DriveWindow 333 DriveWindow DriveWindow connected to the ACS800 RMIO RDCO board and channel CH3 ...

Страница 334: ...DriveWindow 334 ...

Страница 335: ...Control block diagrams 335 Control block diagrams ...

Страница 336: ...Control block diagrams 336 ...

Страница 337: ...Control block diagrams 337 ...

Страница 338: ...Control block diagrams 338 ...

Страница 340: ...www abb com drives www abb com drivespartners Contact us 3AFE68775230 Rev E EN 2012 09 25 ...