Fault tracing

280

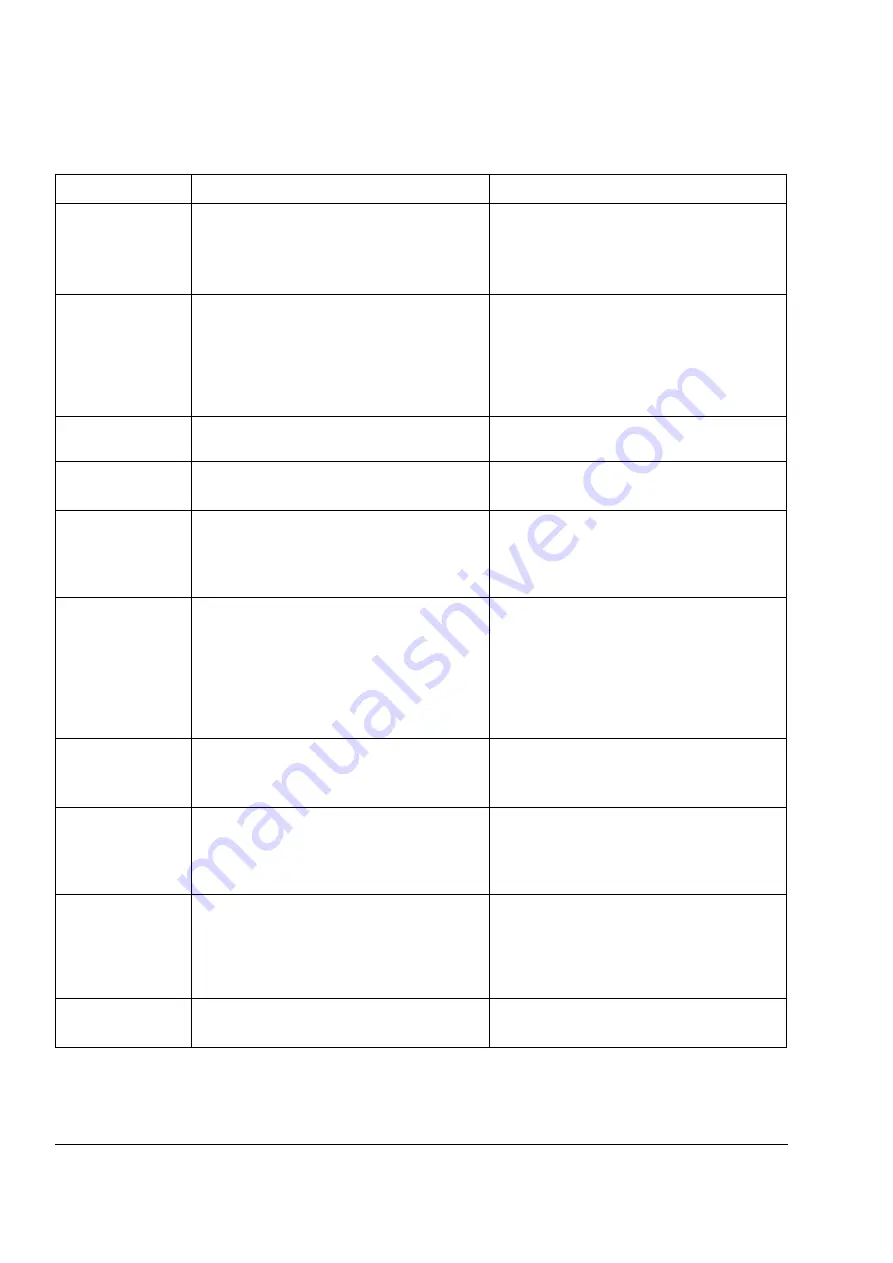

Warning messages generated by the drive

WARNING

CAUSE

WHAT TO DO

ACS800 TEMP

(4210)

3.08 AW 1 bit 4

Drive IGBT temperature is excessive. Fault trip

limit is 100%.

Check ambient conditions.

Check air flow and fan operation.

Check heatsink fins for dust pick-up.

Check motor power against unit power.

AI < MIN FUNC

(8110)

3.09 AW 2 bit 10

(programmable

Fault Function

Analogue control signal is below minimum

allowed value due to incorrect signal level or

failure in control wiring.

Check for proper analogue control signal

levels.

Check control wiring.

Check Fault Function parameters.

AP [message]

Message generated by an EVENT block in the

Adaptive Program.

Consult the documentation or author of the

Adaptive Program.

BACKUP USED

(FFA3)

PC stored backup of drive parameters is

downloaded into use.

Wait until download is completed.

BATT FAILURE

(5581)

3.18 AW 5 bit 15

APBU branching unit memory backup battery

error caused by

- incorrect APBU switch S3 setting

- too low battery voltage.

With parallel connected inverters, enable

backup battery by setting actuator 6 of switch

S3 to ON.

Replace backup battery.

BC OVERHEAT

(7114)

3.18 AW 5 bit 3

Brake chopper overload

Stop drive. Let chopper cool down.

Check parameter settings of resistor overload

protection function (see parameter group

).

Check that braking cycle meets allowed limits.

Check that drive supply AC voltage is not

excessive.

BRAKE ACKN

(FF74)

3.16 AW 4 bit 3

Unexpected state of brake acknowledge signal

See

parameter group

Check connection of brake acknowledgement

signal.

BRK LONG TIME

(FFFC)

3.32 Crane SW bit 9

Brake acknowledge active after brake close

delay has elapsed. Drive active with zero

speed reference.

See

parameter group

Check connection of brake acknowledgement

signal.

Check mechanical brake.

BR OVERHEAT

(7112)

3.18 AW 5 bit 2

Brake resistor overload

Stop drive. Let resistor cool down.

Check parameter settings of resistor overload

protection function (see parameter group

).

Check that braking cycle meets allowed limits.

CALIBRA DONE

(FF37)

Calibration of output current transformers is

completed.

Continue normal operation.

Содержание ACS 800 Series

Страница 1: ...ACS800 Firmware Manual Crane Control Program N697 ...

Страница 4: ......

Страница 26: ...Start up and control through the I O interface 26 ...

Страница 36: ...Quick start up guide 36 ...

Страница 52: ...Control panel 52 ...

Страница 105: ...Program features 105 Figure Control diagram for Shaft synchronisation executed in 20 ms ...

Страница 126: ...Program features 126 The figures below show speed limits according to different load conditions ...

Страница 128: ...Program features 128 ...

Страница 150: ...Application macros control location EXT1 EXT2 150 ...

Страница 228: ...Actual signals and parameters 228 ...

Страница 299: ...Adaptive Programming examples for crane control 299 ...

Страница 305: ...Adaptive Programming examples for crane control 305 ...

Страница 312: ...Adaptive Programming examples for crane control 312 The following figures show the previous example enlarged ...

Страница 314: ...Adaptive Programming examples for crane control 314 The following figures show the previous example enlarged ...

Страница 318: ...Analogue Extension Module 318 ...

Страница 332: ...Additional data actual signals and parameters 332 ...

Страница 333: ...DriveWindow 333 DriveWindow DriveWindow connected to the ACS800 RMIO RDCO board and channel CH3 ...

Страница 334: ...DriveWindow 334 ...

Страница 335: ...Control block diagrams 335 Control block diagrams ...

Страница 336: ...Control block diagrams 336 ...

Страница 337: ...Control block diagrams 337 ...

Страница 338: ...Control block diagrams 338 ...

Страница 340: ...www abb com drives www abb com drivespartners Contact us 3AFE68775230 Rev E EN 2012 09 25 ...