+7 (800) 777-83-75(звонок бесплатный)

type of working environment and at least every 100 hours (

figure 13b

).

If necessary, replace the filter element (clogging of the filter reduces

compressor performance and an inefficient filter causes increased wear).

G

• Replace the oil after the first 100 hours of operation and every 300 hours

subsequently (

figures 14a-14b-14c

). Remember to check the oil level at

B

regular intervals.

Use

SAE 40

. (For cold climates,

SAE 20

is recommended). Never mix

different grade oils. If the oil changes color (whitish = presence of water;

dark = overheated), it is good practice to replace the oil immediately.

• Periodically (or after working with the compressor for more than an hour),

drain the condensate that forms inside the receiver (

fig. 12

) due to the

humidity in the air. This protects the receiver from corrosion and does not

restrict its capacity.

• Spent oil (lubricated models) and condensate MUST BE DISPOSED OF

in accordance with environmental protection regulations and current

legislation.

The compressor must be disposed in conformity with the methods

provided for by local regulations.

5

POSSIBLE FAULTS AND RELATED PERMITTED REMEDIES

FAULT

CAUSE

REMEDY

Leakage of air from the valve of the pressure

switch with the compressor off.

Check valve that, due to wear or dirt on the seal,

does not perform its function correctly.

Unscrew the hexagonal head of the check

valve, clean the valve seat and the special

rubber disk (replace if worn). Reassemble and

tighten carefully (figures

15a-15b

).

Reduction of performance. Frequent start-up.

Low pressure values.

Excessive performance request, check for any

leaks from the couplings and/or pipes. Intake

filter may be clogged.

Replace the seals of the fitting, clean or replace

the filter.

The compressor stops and restarts

automatically after a few minutes.

Tripping of the thermal cutout due to

overheating of the motor.

Clean the air ducts in the conveyor. Ventilate

the work area. Reset the thermal cutout. On

lubricated type models, check oil level and

quality.

After a few attempts to restart, the compressor.

Tripping of the thermal cutout due to

overheating of the motor (removal of the

plug with the compressor running, low power

voltage).

Activate the on/off switch. Ventilate the work

area. Wait a few minutes. The compressor will

restart independently. Remove any power cable

extensions.

The compressor does not stop and the safety

valve is tripped.

Irregular functioning of the compressor or

breakage of the pressure switch.

Remove the plug and contact the Service

Center.

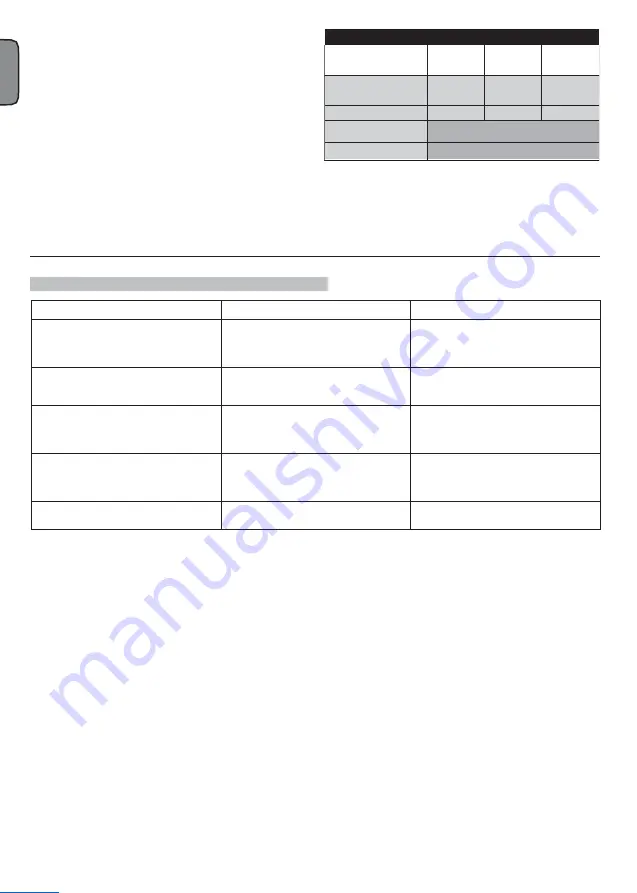

TABLE 1

– MAINTENANCE

FUNCTION

AFTER THE

FIRST 100

HOURS

EVERY 100

HOURS

EVERY 300

HOURS

Cleaning of intake filter and/

or substitution of filtering

element

●

Change of oil

●

●

Tightening of head tension

rods

At start-up and after the first hour of work

Draining tank condensate

Periodically and at the end of work

Содержание Montecarlo O20P

Страница 9: ... 7 800 777 83 75 звонок бесплатный www v p k ru Montecarlo O20P 7 8a 8b min max 8c 9 10a 10b 10c 10d ...

Страница 10: ... 7 800 777 83 75 звонок бесплатный www v p k ru Montecarlo O20P 14c 11 12 13a 13b 14a 14b ...

Страница 11: ... 7 800 777 83 75 звонок бесплатный www v p k ru Montecarlo O20P 15a 15b ...

Страница 79: ... 7 800 777 83 75 звонок бесплатный www v p k ru Montecarlo O20P memo ...

Страница 80: ... 7 800 777 83 75 звонок бесплатный www v p k ru Montecarlo O20P memo ...

Страница 81: ... 7 800 777 83 75 звонок бесплатный www v p k ru Montecarlo O20P memo ...

Страница 82: ... 7 800 777 83 75 звонок бесплатный www v p k ru Montecarlo O20P 9039859 ...