NEED HELP? GIVE US A CALL

833.232.9711

NEED HELP? GIVE US A CALL

833.232.9711

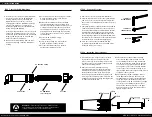

SYSTEM SPECIFICATIONS

16

AOW-4000

Replacement cartridge AOW-4000-CARBON

and AOW-4000-MEM

System Production 83.93 gpd (317 lpd)

TDS Reduction 96.7% + average

Max TDS 1000 ppm

Max water hardness 26 gpg (450 ppm)

Max Chlorine in water 3.0 ppm

Supply water pH limits 4-10

Drain (reject water) flow 1-2x product flow

Empty storage tank precharge 5-7 psi air (35-48 kPa)

Storage tank capacity 3.2 gallons (12.11 liters)

Supply water pressure limits 40-100 psi (275-689 kPa)

Supply water temp. limits 40-100 degrees F (5-37 degrees C)

Efficiency 37.64%

Recovery 47.66%

CAPACITY AT VARIOUS WATER PRESSURE LEVELS (WITH 5 PSI PRECHARGE) U.S. GALLONS

TOTAL VOLUME

20 PSI

30 PSI

40 PSI

50 PSI

60 PSI

70 PSI

3.2

1.4

1.8

2.0

2.2

2.4

2.5

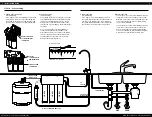

NON-POTABLE WATER SOURCES:

Do not attempt to use this product to make safe drinking water from non-potable water sources. Do not use the system on

microbiologically unsafe water, or water of unknown quality without adequate disinfection before or after the system. This system is certified for cyst reduction and

may be used on disinfected water that may contain filterable cysts.

INSTALLATIONS IN THE COMMONWEALTH OF MASSACHUSETTS:

The Commonwealth of Massachusetts requires installation be performed by a licensed

plumber and does not permit the use of saddle valves. Plumbing code 248—CMR of the Commonwealth of Massachusetts must be followed in these cases.

Do not use with water that is microbiologically unsafe or of unknown water quality without adequate disinfection before or after the system.

Systems certified for cyst reduction may be used on disinfected waters that may contain filterable cysts.

Filter is only to be used with cold water. Systems certified for cyst reduction may be used on disinfected water that may contain filterable cysts.

17

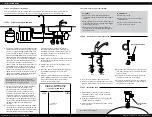

Safeguards

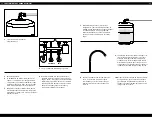

• Use only cold water with filter.

• If you experience a hose connection

leak, disconnect and re-seat the hose.

• When you use the system for the first time,

it will flush the preservative solution from

the RO Membrane and small carbon particles

from the filter cartridges. This may cause a

slight discoloration of the water. As you flush

the system (see startup instructions), this

discoloration will end.

• It is possible for the unit to become

contaminated if it is not operated for a long

period of time. To prevent this from happening,

the system will perform an automatic flush if it

sits idle for three days.

• Disconnect the power and shut off the water

supply before fixing any leaks in the system.

• Do not allow the system to freeze. See

deactivating system in this manual.

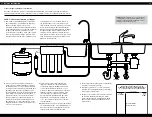

Specifications – Qualified System Performance

Because the performance of a Reverse Osmosis

Membrane is highly dependent upon pressure,

temperature and Total Dissolved Solids (TDS),

the following should be used for comparison

purposes only.

Industry standards measure RO Membranes

performance with no back pressure on the product

water, at 60 psig (414 kPa) and 77°F (25°C). Further

conditions on the above are 250 ppm TDS and a

30.6% recovery rate. Production rate and TDS

reduction figures are for a new Membrane that

has been rinsed for 24 hours. The production rate

of a new Membrane can decrease by 10% per year

or more, depending upon the scaling and fouling

tendencies of the Feed Water.

TDS Reduction measured at 50 psi, 77°±2°F,

and 717 mg/l TDS per NSF/ANSI Standard 58.

Efficiency rating is the percentage of the influent

water to the system that is available to the

user as reverse osmosis treated water. This

measurement is taken under operating

conditions that approximate typical daily usage.

Recovery rating is the percentage of the influent

water to the membrane portion of the system that

is available to the user as reverse osmosis treated

water when the system is operated without a

storage Tank or when the Storage Tank is bypassed.

Flow rate and output are determined

by 3 factors:

1

Incoming water temperature

2

Total dissolved solids (TDS) present in

supply water

3

Incoming water pressure

Lower temperatures are directly proportional to

slower flow rate. All membranes are tested at 77°F.

Incoming water temperature should not exceed

100°F. The RO Filter System should also not be

installed in a location susceptible to freezing. The

more TDS in the supply water, the more filter time

is required. Incoming TDS should not exceed 1000

ppm. Higher water pressure enables a higher flow

rate. Pressure must be above 20 psi for proper sys-

tem operation. The system includes an

integral booster.

Cleaning

To clean your filter unit, wipe down the

exterior with a damp cloth.