39

board and is not covered under the limited warranty.

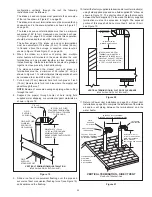

connecting an external supervisory control

The enable/disable circuit is accessed from the CCB’s J6 plug

inside the CCB enclosure, see Figure 3 on page 8 to locate the

CCB enclosure. From the factory there is a short (black) jumper

wire installed between pins 8 and 11 of the J6 plug, see Figure

61 on page 63 to locate the J6 plug.

install field wiring to the enable/disable circuit:

1.

Turn off power at the water heater’s on/off switch and the

breaker that supplies power to the appliance.

2.

Locate the CCB enclosure.

3.

remove the screws from the CCB enclosure cover and

carefully open the CCB enclosure. Note how strain relief for

the wiring is provided between the cover and enclosure along

one edge.

4.

Activate the enable/disable circuit; locate the S1 dipswitch on

the CCB, see Figure 61 on page 63.

• Toggle S1 dipswitch #2 to the open position.

• Toggle S1 dipswitch #3 to the open position.

5.

Locate the black jumper wire between pin 8 and 11 on the

CCB J6 plug, see Figure 61 on page 63 and Figure 62 on page

6.

Cut the black jumper wire in the middle.

7.

Strip approximately 1/2 inch of insulation from the two ends

of the black jumper wire.

8.

Using wire nuts connect two field supplied control wires to

the two ends of the black jumper wire. Wrap electrical tape

around the wire nut connections.

9.

Thread the control wires out of the CCB enclosure with the

other wiring and carefully replace the CCB enclosure cover.

Ensure all wiring is routed through the indented area provided

for strain relief. Ensure no wiring is being pinched.

10.

reinstall the CCB enclosure cover screws and tighten.

11.

route the control wires inside the junction box on the top of

the water heater, see Figure 3 on page 8 to locate the junction

box. Use an available knock-out to route the wires inside the

junction box.

12.

install field supplied control wiring and conduit as required

by national and local codes between the water heater’s

junction box and the external supervisory control. Connect

the wiring from the external control to the control wires inside

the junction box using wire nuts and electrical tape.

13.

Connect the control wiring to a set of dry contacts on the

external control. Follow the control manufacturers instructions

for making connections.

14.

restore power to the water heater.

note:

Whenever the external control opens the set of dry

contacts used, heating operation will be disabled. Whenever

the external control closes the set of dry contacts used, heating

operation will be enabled. A diagonal line and circle appears

over the thermometer icon on the control system’s display when

heating operation is disabled. See the Status icons descriptions

note:

Ensure the water heater is protected from freezing

temperatures when heating operation is disabled. Damage to

the water heater caused by freezing temperatures is not covered

under the limited warranty.

electrical wiring

All electrical work must be installed in accordance with the

National Electrical Code, ANSi/NFPA 70 or the Canadian

Electrical Code, CSA C22.1 and local requirements.

When installed, the water heater must be electrically grounded

in accordance with local codes or, in the absence of local codes,

with the National Electrical Code, ANSi/NFPA 70 or the Canadian

Electrical Code, CSA C22.1.

if any of the original wire as supplied with the water heater must

be replaced, it must be replaced with 105°C rated wiring or its

equivalent, except in the burner housing. in this case use 200°C

rated wire must be used.

power supply connections

read the requirements for the Power Supply on page 13 before

connecting power.

correct polarity:

The water heater’s control system is polarity sensitive and

will lock out and disable heating operation if the polarity of the

power supply is reversed. The control system will display the

“AC reversed” Fault message on the LCD. The 120 VAC hot

wire from the power supply must connect to the black wire in the

junction box and the 120 VAC neutral wire must connect to the

white wire in the junction box for correct polarity.

Power supply connections must be made as follows:

1.

Ensure the power supply is turned off at the breaker or

disconnect switch.

2.

remove the junction box cover. See Figure 3 on page 8 for

junction box location.

3.

Connect the 120 VAC hot wire from the power supply to the

black wire in the junction box on top of the water heater with a

properly sized wire nut. Wrap electrical tape around the wire

nut and wire end. See wiring diagrams Figure 62 on page 64

4.

Connect the 120 VAC neutral wire from the power supply to

the white wire in the junction box. Wrap electrical tape around

the wire nut and wire end. See wiring diagrams Figure 62 on

page 64 and Figure 63 on page 65.

5.

Connect the ground wire from the power supply to the

grounding lug inside the junction box. See wiring diagrams

Figure 62 on page 64 and Figure 63 on page 65.

6.

replace the junction box cover when connections are

complete.

note:

Do not apply power to the water heater before installation

is complete and the water heater is filled with water.

enaBle/disaBle circuit

The water heaters covered in this manual are equipped with

an enable/disable circuit for use with field supplied external

supervisory controls such as time clocks or building Building

management Systems. The enable/disable circuit may be used

to disable heating operation during periods when the building is

unoccupied or there is no demand for hot water.

To use the enable/disable circuit it must first be activated by

configuring the S1 dipswitch on the water heater’s CCB (central

control board), see Figure 61 on page 63. Field supplied wiring

is then installed between the water heater’s CCB and a set of

“dry contacts” (no voltage or load) on the field supplied external

control.

note:

The water heater’s enable/disable circuit is a switching

circuit only: Do not apply external voltage or connect any load

(iE: relay coil) to this circuit. This will damage the CCB circuit

Содержание 101 Series

Страница 75: ...75...