Operating and Assembly Instructions – A.B.S. Flexilo for wood pellets

General Information

Subject to technical change

Issue 09/2016

Page 4 of 30

©A.B.S. Silo- und Förderanlagen GmbH

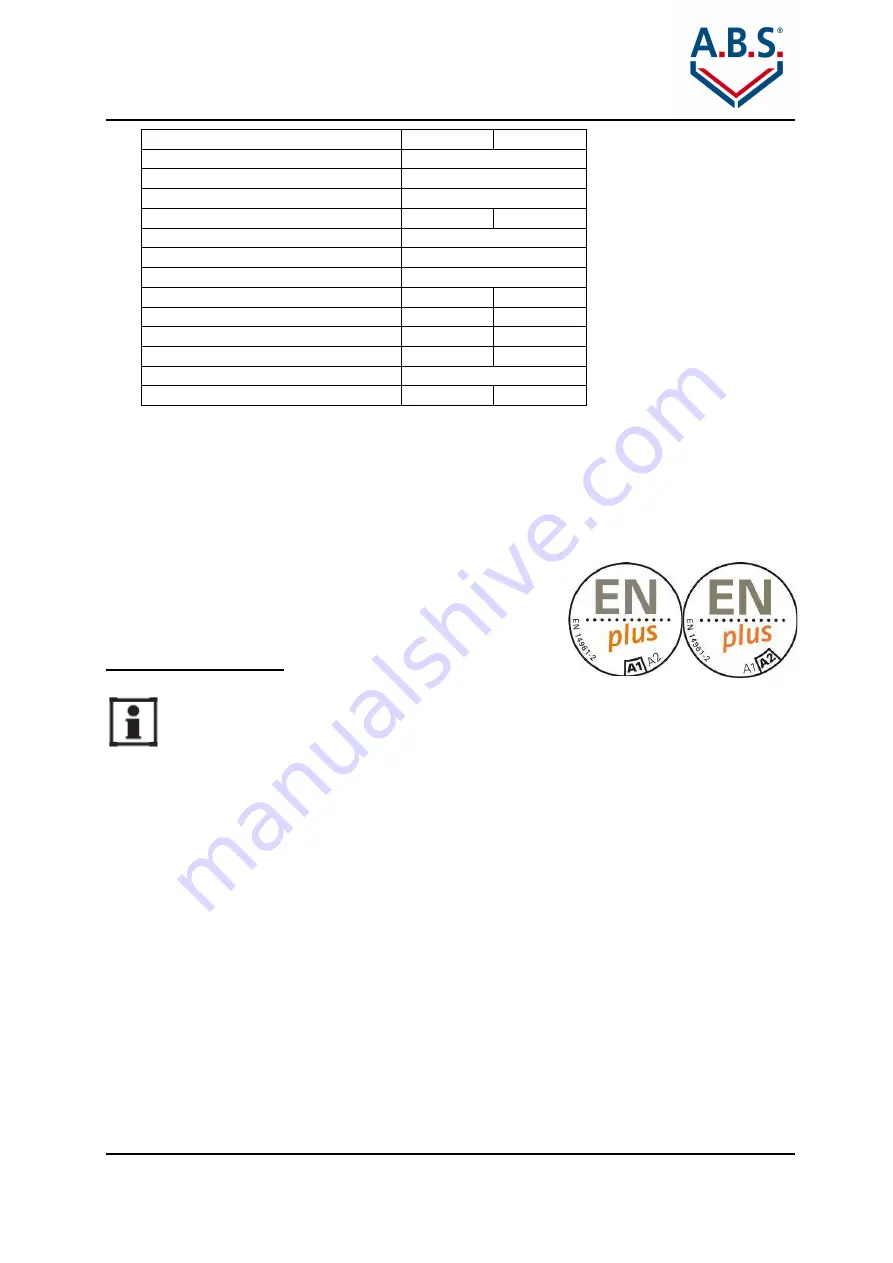

Quality A1 Quality A2

diameter (mm)

6 or 8

length(mm)

3,15 to 40

moisture content (% by mass)

<=10

ash content (% by mass)

<=0,7 <=1,2

mechanical strength (% by mass)

>=97,5

finest content (% by mass)

<=1

overlength (40 – 45 mm)

<=1

heating value (kWh/kg)

4,6 to 5,3

bulk density (kg/m³)

>=600 600 – 700

nitrogen content (% by mass)

<=0,3 <=0,5

sulphur content (% by mass)

<=0,04 <=0,05

chlorine content (% by mass)

<=0,02

ash fusion temperature* (C°)

>=1200 >=1100

* This value is only mandatory for ENplus certified pellets. It refers to the temperature at

which the wood ash deforms and thus can lead to scorification in the combustion chamber.

Poor quality pellets can impair operation of your heating system and have an adverse effect

on the storage and conveying equipment. Only high-grade pellets can assure reliable and

problem-free operation of the pellet-fired boiler and the conveying systems. If necessary,

have the supplier confirm the quality of the pellets.

ENplus certificate

ENplus certified pellets are available for quality classes A1

and A2. Manufacturers and suppliers of high quality wood

pellets and further information can be found under

www.enplus-pellets.de.

1.4 Approvals and Compatibility to Pellet Boilers

There are approvals of various boiler manufacturers for the A.B.S. Flexilo SPRING.

Through individual solutions of extraction devices and conveying systems in special cases

connections to the silo can be created.

Please comply with your country-specific standards and directives regarding

assembly and operation of the silo! Observe the information contained in these

instructions! It is binding and must be observed.