3D SYSTEMS, INC.

75-D059 REV_A

17

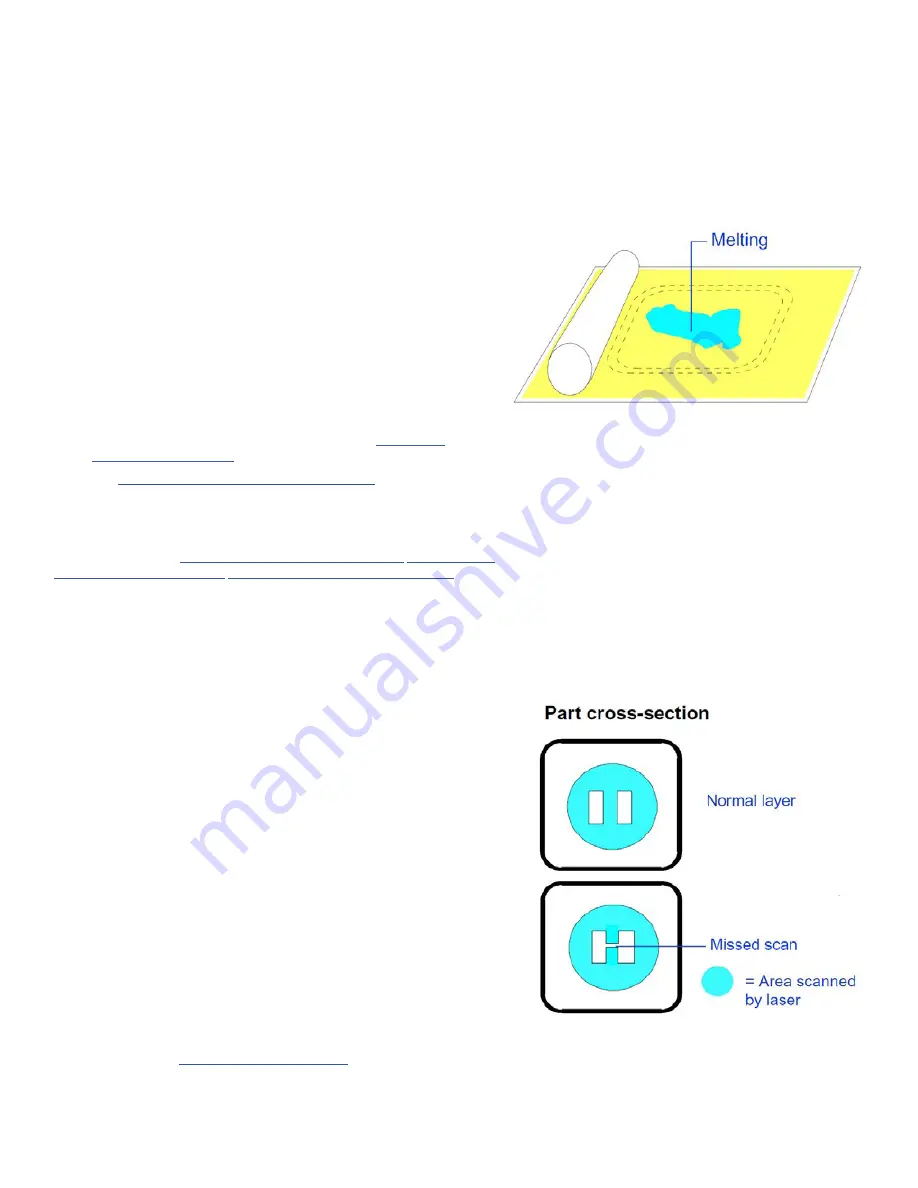

MELTING, PRINT BED

Description:

The material in the print bed melts and solidifies.

Theory of Cause:

Possible causes include:

• IR sensor not calibrated correctly or dirty

• Part Heater setpoint too high

• Short feeds

• System trying to reach the temperature setpoint too quickly

Visual Signs:

Melting first occurs in small patches in the hottest areas

of the print bed. Observing which areas melt first indicates the hottest

spots in your print bed .

Consequences

: Melting occurs after glazing . The print bed temperature

increases . Melting is a far more serious condition than glazing .

Corrective Action:

Terminate the build . There are several actions you

can take to prevent melting:

• In the Print Parameters Profile, reduce the Part Heater setpoint

and/or use ramping for the heater setpoints .

• Make sure IR sensor block temperature is correct and that the

core heater is working .

• Perform an Offline IR sensor calibration. See

• See

“Cleaning Up the SLS System” on page 9.

If none of the above actions prevents melting, call certified service

personnel to calibrate the IR sensor and/or adjust

the thermocouples .

Related Problems:

“Cracking of Print Bed” on page 14,

“Glazing , During Print” on page 14.

MISSED SCAN

Description:

The laser does not completely scan the fill area in a part.

Theory of Cause:

The STL file is incorrect. This problem is not material

related .

Visual Signs:

You can observe that the scanned area is incorrect .

Consequences:

The part geometry is incorrect, and the part may have

poor properties .

Corrective Action:

Depending on the severity of the problem, you may

need to terminate the print and start over . If the missed scan occurs

only on one layer or slice, you may be able to complete the print .

If you experience missed scans, make it a practice to verify that the

STL file is not missing facets and that the normals are correct prior

to beginning a print by using the Preview application. If the STL file is

incorrect, you next need to verify that the original CAD file is correct.

If the original CAD file is correct

, the STL file could be corrupt. Generate a

new one and preview the print again . If the problem recurs, contact 3D

Systems

customer support .

If the original CAD file is incorrect

, make the necessary changes to the

CAD file and save the file in STL format. With the new file, set up a build

packet and print the part again .

Related Problems: