MultiScanner

®

i

320

OneStep

®

Multifunction Wall Scanner

1. INSTALLING THE BATTERY

Press battery door release in with your finger or a coin and lift up

to remove door. Connect 9-volt battery to cable. Place into the

compartment and press into place. Replace battery door and snap shut.

Battery will last approximately 2 years under normal conditions.

2. SELECTING THE MODE

Move selector switch to the desired mode: STUD SCAN for finding wood

or metal studs; DEEPSCAN

®

for scanning walls over

3

⁄

4

in. (19 mm);

or METAL SCAN for locating metal.

Unit will remain off if POWER BUTTON is not pressed.

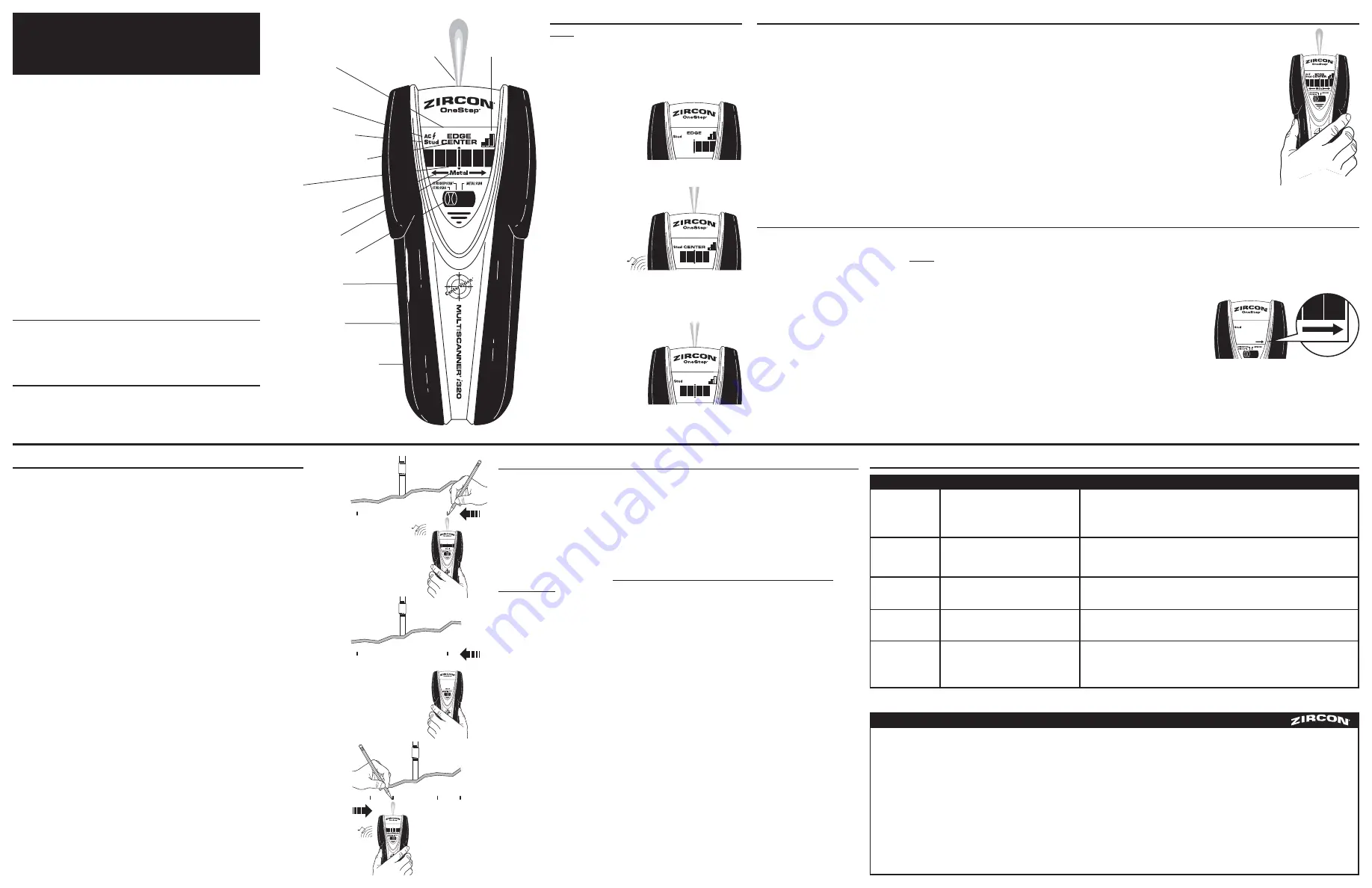

3. FINDING A STUD

Always scan for studs with the scanner placed

flat against the wall. Move the mode switch to

STUD SCAN, place the tool flat against the wall,

then press and hold the Power button.

Wait for beep to confirm calibration has

completed before moving scanner.

Slowly slide tool across

surface. EDGE display

will illuminate, indicating

location of the stud edge.

Continue sliding tool.

When the center of

a stud is located

with three bars on

the Signal Strength

Indicator, the four

Middle bars, CENTER

display, and SpotLite

®

Pointing System will

all illuminate and

the buzzer will sound.

In cases of deeper studs

(thicker walls), when the

center of the stud is

located only two bars

will show on the Signal

Strength Indicator and

only the SpotLite

®

Pointing System and

four Middle bars will

illuminate. If you still

can’t locate a stud,

try STUD DEEPSCAN

®

mode.

4. OPERATING TIPS

For optimum scanning results, it is important to properly hold the MultiScanner

®

i

320 and move slowly when scanning. The following tips will provide

more accurate scanning results:

• Grasp the handle with your thumb on one side and your fingers on the other side. Make sure your fingertips are resting on or above the running

board and not touching the surface being scanned or the scanning head of the tool.

• Hold the tool straight up and down, parallel to the studs, and do not rotate the tool.

• Keep tool flat against the wall and do not rock, tilt, or press hard when slowly sliding across the surface being scanned.

• Avoid placing your other hand, or any other part of your body, on the surface being scanned. This will interfere with the tool’s performance.

WireWarning

®

Detection

Zircon’s WireWarning

®

detection feature works continuously in all modes. When live AC voltage is detected, the AC detection warning indicator will

appear in the display. If scanning begins over a live AC wire, the AC indicator will flash continuously. If this occurs, release the Power button,

move the tool over, and recalibrate in a new location. Once calibration has completed, begin to slide the tool in the direction of your initial calibration.

CAUTION: Wires deeper than 2 in. (51 mm) from the surface, in plastic conduit, or behind plywood shear wall, or metallic wall covering

may not be detected. Metal shielded wires or those in metal conduit will not be detected. Use extreme caution under these circumstances

or whenever live AC wiring is present.

Always turn off power when working near electrical wires.

5. CALIBRATING THE TOOL IN STUD SCAN/STUD DEEPSCAN

®

MultiScanner

®

i

320 can be calibrated anywhere on the wall. It provisionally monitors the subsurface environment 10 times per second and automatically recalibrates,

when needed, to successfully find the center of studs in one step.

• Place MultiScanner

®

i

320 against the wall

before

pressing the Power button in STUD SCAN or STUD DEEPSCAN

®

mode.

• Once powered on, tool will automatically perform all calibrations. The LCD will display all icons until calibration is complete. Upon completion of calibration, the SpotLite

®

Pointing System and buzzer will momentarily activate and the tool will begin continuous measurements. Continue to press power button down and keep the tool flat against

the wall and begin scanning.

Note: It is important to wait for calibration to complete (1–2 seconds) before moving the scanner.

•

ACT

™

(Auto Correcting Technology)

—During scanning, the tool will automatically recalibrate itself when needed.

This recalibration is transparent and no indication is made. If an arrow icon illuminates, the tool calibrated near

or over a stud and then moved away. The arrow indicates the direction of the missed stud.

6. WORKING WITH DIFFERENT MATERIALS

Wallpaper:

The MultiScanner

®

i

320 functions normally on walls covered with

wallpaper or fabric, unless the materials are metallic foil, contain metallic fibers,

or are still wet after application.

Wallpaper may need to dry for several weeks

after application.

Freshly painted walls:

May take one week or longer to dry after application.

If it is difficult to locate a stud in STUD SCAN mode on fresh paint, switch to

METAL SCAN mode to locate nails or drywall screws holding drywall to studs.

Lath & plaster:

Due to irregularities in plaster thickness, it is difficult for the

MultiScanner

®

i

320 to locate studs in STUD SCAN mode. Change to METAL

SCAN mode to locate the nail heads holding wood lath to the studs. If the

plaster has metal mesh reinforcement, MultiScanner

®

i

320 will be unable to

detect through that material.

Extremely textured walls or acoustic ceilings:

When scanning a ceiling or wall

with an uneven surface, place thin cardboard on the surface to be scanned and

scan over the cardboard in STUD DEEPSCAN

®

mode. If irregular scanning results are

received, switch to METAL SCAN mode to locate nails or drywall screws that line up

vertically where a stud or joist is positioned.

Wood flooring, subflooring, or gypsum drywall over plywood sheathing:

Use DEEPSCAN

®

mode and move the tool slowly. The Signal Strength Indicator

may only display 1 or 2 bars when the tool locates a stud through thick surfaces.

MultiScanner

®

i

320 cannot scan for wood studs and joists through carpet and

padding. In problematic situations, try using METAL SCAN to locate nails or screws

that may line up vertically where a stud or joist is positioned.

Note: Sensing depth and accuracy can vary due to moisture, content of materials,

wall texture, and paint.

FCC Part 15 Class B Registration Warning

This device complies with Part 15 of FCC Rules. Operations subject to the following

two conditions: (1) this device may not cause harmful interference, and (2) this

device must accept any interference received, including interference that may cause

undesired protection.

7. SCANNING IN METAL MODE

Note: When scanning for studs, use STUD SCAN mode (or Stud DEEPSCAN

®

mode on thicker walls)

to quickly locate the center and edges of wood or metal studs. Use METAL SCAN to determine

if the previous reading in STUD SCAN was a wood stud, metal stud, or pipe. In METAL SCAN,

only metal drywall screws will be found in wood studs, while metal will be indicated everywhere

on a metal stud or pipe.

METAL SCAN has interactive calibration that allows you to adjust its sensitivity to metal, which can

be used to find the precise location of metal objects in walls, floors, and ceilings. Maximum sensitivity

is ideal for quickly finding the approximate location of metal. However, sensitivity can be reduced by

calibrating the tool closer to metal. With reduced sensitivity, the area where metal is indicated will

be smaller. But in both cases, the metal target is in the center of the area where the tool indicates

metal is present.

1. Move mode switch to METAL SCAN mode. For maximum metal sensitivity, turn the tool on in the

air by pressing and holding the power button. This will ensure that it calibrates away from any metal

objects. (The tool can only be calibrated off the wall in METAL SCAN mode.)

2.

(Figure A)

While holding the power button, press the tool flat against the wall and slowly slide the

scanner across the surface. Mark the point where you get the highest metal indication (the most Middle

bars on the screen). If it is a strong target, the SpotLite

®

Pointing System will also shine a beam of light

and a steady beep will sound. Continue in the same direction until display bars reduce. Reverse direction

and mark the spot where the display bars peak from the reversed direction. The midpoint of the two

marks is the location of the center of the metal object.

If the unit indicates metal over a large area, you can refine the scanning area to more accurately locate

the metal target by following steps 3 and 4 below.

3.

(Figure B)

To further pinpoint the location of the metal target, scan the area again. Release the

power button and then turn the unit back on, this time starting on the wall over one of the previous

marks. This will reset the tool to a lower sensitivity and narrow the scan area.

4.

(Figure C)

To continue to reduce sensitivity and further refine the scanning area, repeat step 3.

This procedure can be repeated multiple times to narrow the field even further.

Note: If any bars display on the screen, metal is present. Small targets or targets deep within the surface

may only illuminate some of the bars and not the center line or audio tone. In this case, use the highest

indication to determine the metal position.

SpotLite

®

Pointing System

LCD Display

Mode Selector Switch

Battery (back of unit)

Stud Scan Mode Indication

Stud Edge or Center Indication

WireWarning

®

Detection Indication

Middle Bars

Metal Mode Indication

ACT

™

(Auto Correcting

Technology) Indication

Signal Strength

Indicator

Running Board

Power Button

Detects other objects

besides studs in

STUD SCAN mode.

Finds more targets

than there should be.

Difficulty detecting

metal.

Image of metal object

appears wider than

actual size.

Constant readings of

studs near windows

and doors.

You suspect electrical

wires, but do not

detect any.

• Electrical wiring and metal/plastic pipes may

be near or touching back surface of wall.

• Tool calibrated over metal object.

• Metal targets too deep or small.

• Metal has greater density than wood.

• Double and triple studs are usually found

around doors and windows. Solid headers

are above them.

• Wires are shielded by metal conduit,

a braided wire layer, or metallic wall covering.

• Wires deeper than 2 inches (51 mm) from

surface might not be detected.

• Wires may not be live.

• Scan the area in METAL SCAN mode to determine if metal is present.

• Check for other studs equally spaced to either side (12, 16, or 24 inches [305, 406, or 610 mm])

apart or the same stud at several places directly above or below the first scan area.

• A stud reading would measure approximately 2 inches (51 mm) apart from each edge; anything

larger or smaller is most likely not a stud if not near a door or window.

• The scanner may have been calibrated over a metal object, reducing sensitivity.

Try calibrating in another location.

• Scan in both horizontal and vertical directions. Metal sensitivity is increased when

metal object is parallel to sensor, located under Zircon logo.

• To reduce sensitivity, recalibrate MultiScanner

®

i

320 over either of first two marks

(Metal mode only–See Step 7).

• Detect outer edges so you know where to begin.

• Try METAL SCAN to see if you can find metal, wire, or metal conduit.

• Try turning on switches to outlet.

• Try plugging a lamp into outlet and turning on switch.

8. HELPFUL HINTS

(See also number 4, OPERATING TIPS)

Situation

Probable Cause

Solution

The MultiScanner

®

i

320 OneStep

®

features three

scanning modes:

• STUD SCAN: Locates the center and edges of wood

and metal studs up to

3

⁄

4

in. (19 mm) deep

• STUD DEEPSCAN

®

: Locates the center of wood

and metal studs up to 1

1

⁄

2

in. (38 mm) deep

• METAL SCAN: Detects and locates ferrous (magnetic)

metal (such as

1

⁄

2

in. rebar) up to 3 in. (76 mm) deep

and non-ferrous (non-magnetic) metal up to 1

1

⁄

2

in.

(38 mm) deep

WireWarning

®

detection automatically detects

and alerts of live AC wires in STUD SCAN,

STUD DEEPSCAN

®

, and METAL SCAN modes.

When AC voltage is detected, the AC Wire Warning

®

icon will be displayed on screen.

Note: This product is intended for use in the

U.S.A. and Canada only.

Figure A

Figure B

Figure C

LIMITED 1 YEAR WARRANTY

Zircon Corporation, (“Zircon”) warrants this product to be free from defects in materials

and workmanship for one year from the date of purchase. Any in-warranty defective product

returned to Zircon*, freight prepaid with proof of purchase date and $5.00 to cover postage

and handling, will be repaired or replaced at Zircon’s option. This warranty is limited to

the electronic circuitry and original case of the product and specifically excludes damage

caused by abuse, unreasonable use or neglect. This warranty is in lieu of all other warranties,

express or implied, and no other representations or claims of any nature shall bind or

obligate Zircon. Any implied warranties applicable to this product are limited to the one

year period following its purchase. IN NO EVENT WILL ZIRCON BE LIABLE FOR ANY SPECIAL,

INCIDENTAL OR CONSEQUENTIAL DAMAGES RESULTING FROM POSSESSION, USE OR

MALFUNCTION OF THIS PRODUCT.

In accordance with government regulations, you are advised that: (i) some states do not

allow limitations on how long an implied warranty lasts and/or the exclusion or limitation

of incidental or consequential damages, so the above limitations and/or exclusions may not

apply to you, and further (ii) this warranty gives you specific legal rights and you may also

have other rights which vary from state to state.

Return product freight prepaid with proof of purchase date (dated sales receipt) and $5.00

to cover postage and handling, to:

Zircon Corporation

*Attn: Returns Department

1580 Dell Avenue

Campbell, CA 95008-6918 USA

Be sure to include your name and return address. Out of warranty service and repair, where

proof of purchase is not provided, shall be returned with repairs charged C.O.D. Allow 4 to 6

weeks for delivery.

Customer Service, 1-800-245-9265 or 1-408-963-4550

Monday–Friday, 8:00 a.m. to 5:00 p.m. PST

E-mail: [email protected]

U.S. Patents 6023159, 6259241, 6989662, 7116091, and 7148703, Canadian Patents 2141553,

2341385, and Patents Pending, Japanese Patents 3581851, 4152361, and Patent Pending,

German Patent 693338849, French and U.K. Patents 657032, and E.U. Patents Pending

©2009 Zircon Corporation • P/N 60943 • Rev A 02/09

Visit www.zircon.com/support for the most current instructions.

ACT, CenterVision, DeepScan, MultiScanner, OneStep, SpotLite, WireWarning, and Zircon are registered trademarks or trademarks of Zircon Corporation.