Installation and Startup Guide

This document covers the installation of MT607/610i Series, for the detailed specifications and operation,

please refer to Datasheet and relevant User Manual.

Install Environment:

NEMA Rating

MT607/610i

is NEMA 4X rated.

Electrical

Environment

MT607/610i

has been tested to conform to European CE requirements. This

means that the circuitry is designed to resist the effects of electrical noise. This

does not guarantee noise immunity in severe cases. Proper wire routing and

grounding will insure proper operation.

Environmental

Considerations

(1) Make sure that the displays are installed correctly and that the operating

limits are followed. Avoid installing units in environments where severe

mechanical vibration or shocks are present.

(2)

Do not operate the unit in areas subject to explosion hazards due to

flammable gases, vapors or dusts.

(3) Do not install the unit where acid gas, such as SO2 exists.

(4)

This device should be mounted in the vertical position and for use on the flat

surface enclosure.

(5)

Conform to UL508 (ISBN 0-7629-0404-6) machine safety for use in

Pollution Degree 2 Environment.

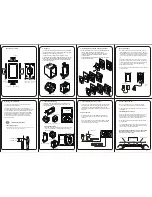

Unpacking the Unit

Unpack and check the delivery. If damage is found,

notify the supplier.

Installation Instructions

Secure the operator panel in position, using all the fastening holes and the provided brackets

and screws:

Type A(mm)

B(mm)

MT607i 192 138

MT610i 260 202

Power Connections

System Settings

Power up HMI, click CECP to do touch screen calibration, backlight adjustment, or screen rotation.

MT607i MT610i

Installation Instruction

1

2

NOTE:

Place the operator panel on a stable

surface during installation. Dropping it or

letting it fall may cause damage.

3

(1) Installation Instruction, 2-sided A4 *1

(2) Human Machine Interface *1

(3) Power Connector *1

(4) Brackets & Screws V2.1 *1 pack

(5) Fuse 1.25A/250V 5*20mm *1

5

4

NOTE:

1.

Connect positive DC line to the ‘+’ terminal

and the DC ground to the ‘-' terminal.

2. Please do not connect HMI with PLC and PC

simultaneously to prevent potential difference

from destroying USB ports of HMI and PC.

To make a connection, strip about 3/8” of

insulation off the end of the wire, turn the

connector screw counterclockwise until the gap

is wide open, insert the wire all the way in, and

turn the screw clockwise until it’s tight.

(A)

(B)

Cutout

(1)

(2)

(5)

(4)

(3)

( Note 1: For the details of HMI

DIP SW function settings please

refer to Part 8 in this guide. )