1

WARNING:

Read all instructions and safety warnings before

operating this equipment. Failure to follow the

instructions and safety warnings may result in

personal injury or property damage.

!

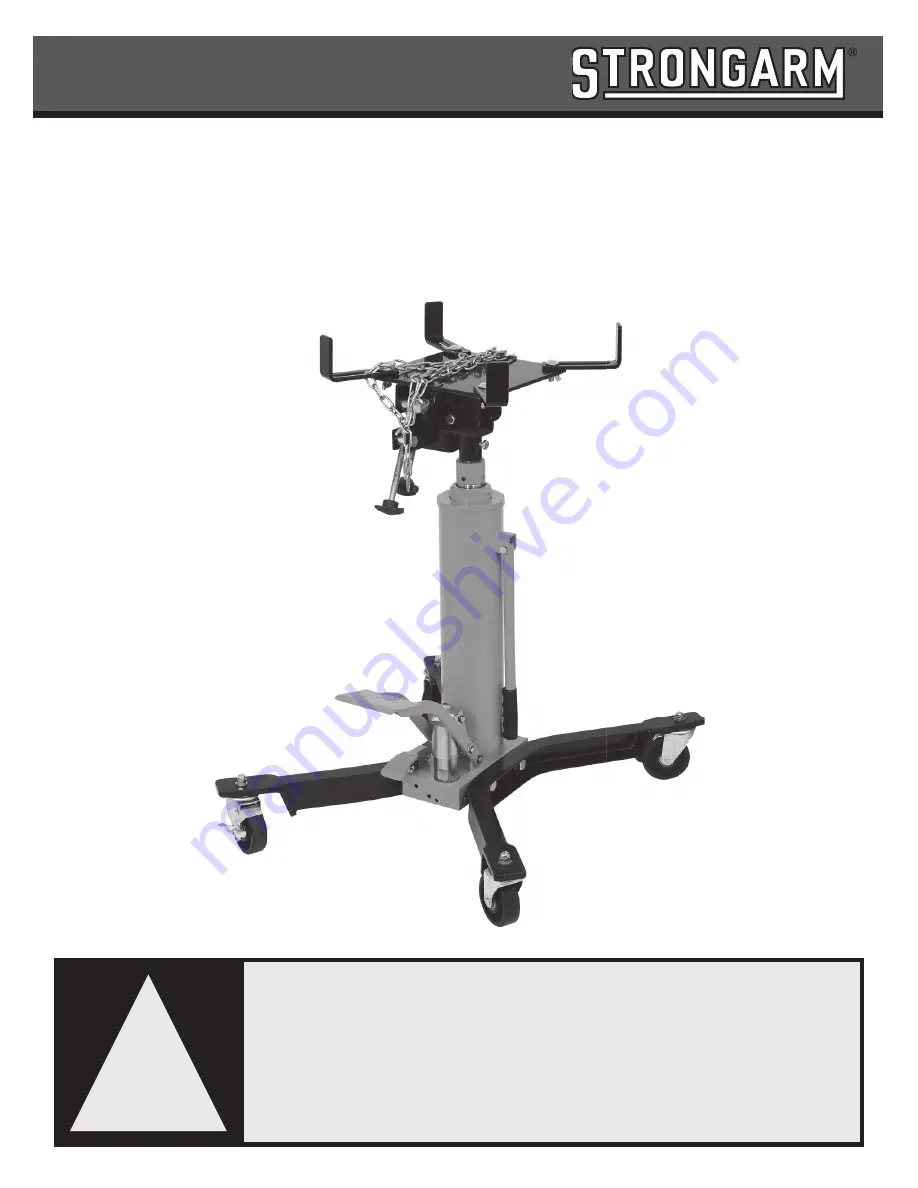

PROD NO. 030535

MOD NO. 814B

1/2 Ton High Lift Transmission Jack

Owner’s Manual