ABN 92 510 718 068

Web site:

http://www.spiritdesign.com.au

SDLocoY1 - Victorian Railways Y class diesel-electric.

Requires LifeLike SW9/1200 loco to complete, available separately.

Thank you for purchasing this kit and I hope you get many hours of enjoyment from it. Chris Pearce (Spirit Design)

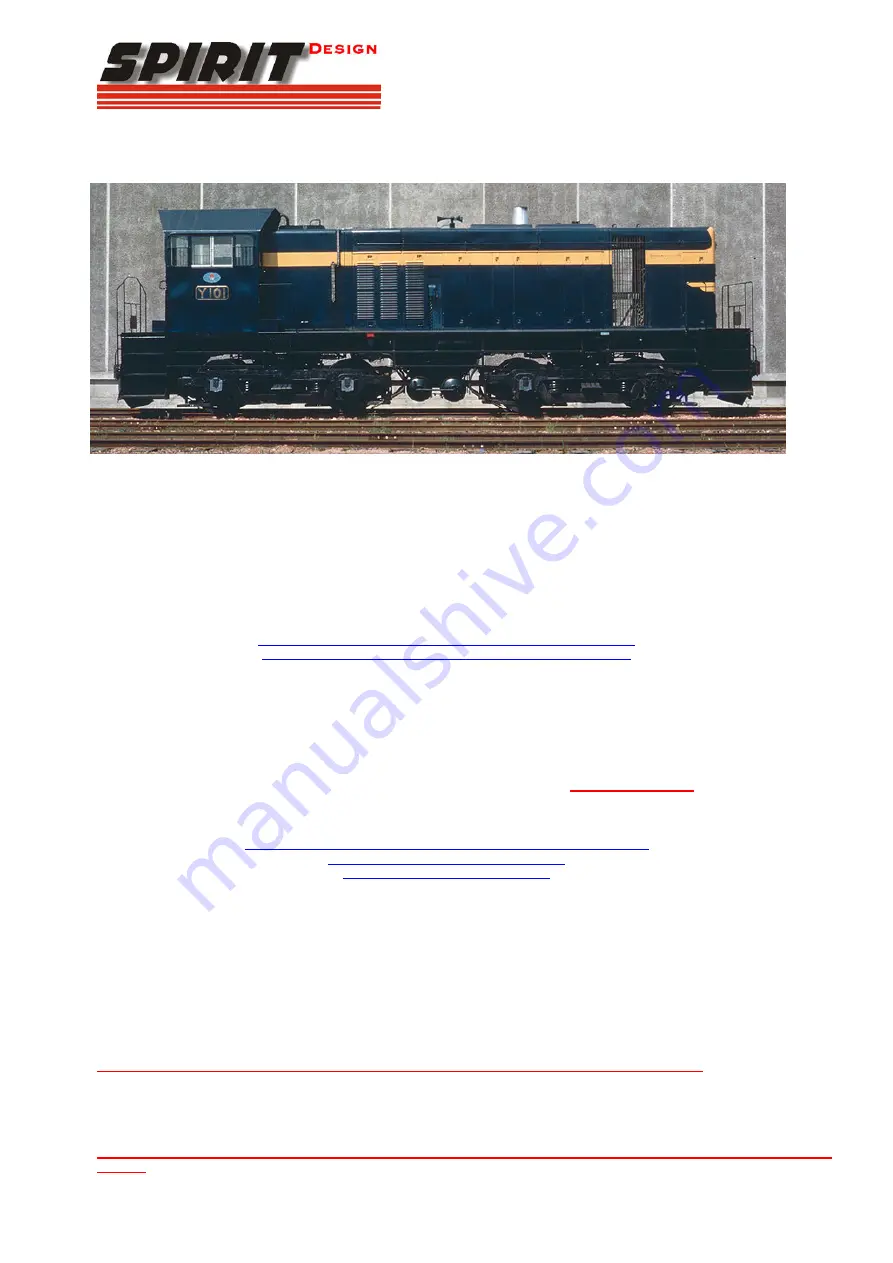

Brand new Y101 arrives from Clyde and is seen outside Dynon. Victorian Railways photo

Basic history: The Y class was the second-largest diesel class of the Victorian Railways with 75 members being built by Clyde’s

Granville workshops in 3 batches between 1963-1968. Utilising bogies off scrapped swing door electric trains and featuring a 6-

cylinder EMD 567 and later a 645 engine they were highly regarded by crews and were a versatile go-anywhere engine. The long

hood is designated the no1 end and controls were arranged accordingly. The fleet was seen over the entire VR system with 4 always

on the standard gauge. Later on, in life, they received the V/line orange and grey livery and this was later replaced on the

remaining active units with the new V/line red and blue. Some were fitted with DOO window openings altering their appearance. A

few have made their way into private tourist railways and are still giving reliable service.

Soldering: Always clean up soldered joints as you progress, as it’s easier in the long run. For an understanding of soldering it

would pay to visit the following sites for information on soldering before attempting your first kit.

http://themodelmakersresource.co.uk/articles/article012.html

http://www.dccconcepts.com/index_files/DCCsoldering1.htm

Tools needed: small files, sanding sticks, fine grade sandpaper, fast-drying wood glue, Selley’s Kwik Grip hydrocarbon-based,

‘Duck Bill’ (flat – no teeth) and long nose pliers, Plyobond or superglue, soldering iron, solder, flux, Exacto knife, scissor clamps,

weights, soldering aids, Blu-Tak, 0.3mm drill bit, pin vice, tweezers.

Other items: decoder wire, 2B pencil, paint, couplers, LifeLike SW9/1200 loco for motor, bogies, weights and phosphorous bronze

pickups etc

Assembly Instructions: Some steps require close attention and they are highlighted

in bold and italics!

Parts referred to in the

text are marked (P1), (P2) etc. All brass parts and their holding tabs should be trimmed and filed after removing from the etch.

Reference photos:

http://www.victorianrailways.net/motive%20power/ydie/ydie.html

http://www.robx1.net/index/index.htm

http://www.pjv101.net/index.htm

Train Hobby Y class profile book

Walkway:

1.

Cut the centre section holding the small parts away from the walkway etch (P1)

2.

Remove the walkway (P1) from the etch and fold sides up to 90degrees using a ‘Hold ‘n’ Fold’ or between 2 bars of

hardened ground steel

3.

Bend ends of the walkway (headstock skirts) to 90 degrees.

4.

Fold a staircase side (P2), then the bottom of the step up to meet the side and solder. Do this for all 4 (P2) staircases

5.

Tests fit a staircase (P2) and once satisfied with the fit, solder it into the floor making sure that the tab in the top slots into

the hole provided in the walkway. Also, make sure the staircase is square and straight with the front/rear walkway and the

headstock skirts. Then solder the edge of the stair casing to the walkway skirt. Repeat for the other 3 staircases (P2).

Note the side part of the case is positioned away from the front/rear skirt of the walkway

6.

Where the stair casing (P2) comes through the walkway (P1), cover this area over with solder and file the tab to make the

walkway decking flush

7.

Clean up any excess solder on the completed walkway and make sure the centre area is free from etching holding tabs and

set aside once the entire walkway is flat and straight when sitting on a flat surface

8.

Make sure that the walkway is straight and flat and if twisted use pliers/steel bars to achieve a perfectly flat

surface

. See the walkway picture below