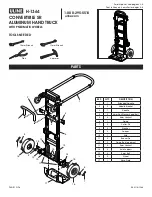

DESCRIPTION

Structure in aluminium Ø80

Powder coated

3.0 x 2.0 m

CONFORM

ASSEMBLY INSTRUCTION

ALUMINIUM FOLDING GOAL, MOBILE

PRODUCT REF

:

S16118

PAIR

ASSEMBLY TIME

The assembly time for this goal is estimated between 30 to 45 minutes at 2 persons (without concreting).

TEST AFTER INSTALLATION

According to the regulation above, this product has to be tested as below:

- Put 180kg at 20cm from the ground and in the middle of the crossbar for 1min.

- Apply an horizontal force of 110 kg on the middle of the crossbar, by a 3 meter rope, for 1min.

After these tests, the equipment and the fixation system should not have a break, move or show residual

deformation.

During the first installation, stability and strength tests are compulsory.

Every time you install the equipment, a visual check of the stability and strength must be realized.

The owner of this equipment must usually control the product.

For an optimal use of our products, we advise to follow the installation and maintenance instructions.

MAINTENANCE

The equipment has to be regularly maintained by the owner. It is recommended to:

- Check every week that all the bolts are correctly tightened.

- Fix paint defects if the unit has been damaged, using the adapted paint specified by the manufacturer.

- Replace all damaged or missing parts with a spare part recommended by the manufacturer.

- Clean the product by using dishwasher soap, clean water, and soft cloth.

WARRANTY

One full year parts and labour guarantee. Every claim regarding the condition of the delivered equipment has to be

done within the warranty period following receipt of the product.

The warranty will not apply to:

- Any degradation during transport.

- Any degradation due to poor maintenance.

- Any degradation due to use differing from which the product was intended.

- Any defect claimed after the end of the warranty period.

- Any damage due to a faulty installation or assembly of the product.