Summary of Contents for SA800

Page 1: ...SASOO SOl DisketteStorageDrive 2 J 2 J 2 J C J ShUgart Associates ...

Page 2: ...SA800 801 DisketteStorageDrive 2 J 2 2 C J Copyright 1977 Shugart Associates ...

Page 4: ......

Page 6: ......

Page 10: ......

Page 23: ...WRITE PROTECT DETECTOR INDEX SECTOR LED 19 EJECT MECHANISM ...

Page 24: ......

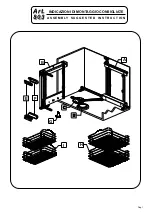

Page 26: ... I Jumper Plug Installed as Shipped Test Point SA800 801 PCB Component Location 22 ...

Page 27: ...23 SA800 801 LOGIC MANUAL ...

Page 28: ......

Page 35: ...31 SA800 801 SCHEMATIC DIAGRAMS ...

Page 36: ......