SERVICE MANUAL

CODE: 00ZAL1250/A1E

DIGITAL COPIER

AL-1020

AL-1200

AL-1220

MODEL

AL-1250

* This Service Manual describes only the differences from

the AL-1000/1010. For the common items with the

AL-1000/1010,please refer to the AL-1000/1010 manual.

CONTENTS

SHARP CORPORATION

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

Parts marked with " " is important for maintaining the safety of the set. Be sure to replace these parts with specified

ones for maintaining the safty and performance of the set.

[ 1 ] GENERAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 1

[ 2 ] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 1

[ 3 ] EXTERNAL VIEWS AND INTERNAL STRUCTURE . . . . . . . . . . . . 3 - 1

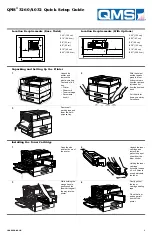

[ 4 ] UNPACKING AND INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . 4 - 1

[ 5 ] OPERATIONAL DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 1

[ 6 ] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 2

[ 7 ] SIMULATION,TROUBLE CODES . . . . . . . . . . . . . . . . . . . . . . . . . . 7 - 1

[ 8 ] USER PROGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 1

[ 9 ] ELECTRICAL SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 1

[10] CIRCUIT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 - 1

●

PARTS GUIDE

AL-1250