TORG

is composed by an aluminum pressure die-cast monobloc, into which

reduction gears are contained. If there is an obstacle in front of the gate while it is

moving, the

mechanical clutch

guarantees the

anti-crushing safety

.

In case of power supply or servicing lacking,

TORG

has a release system which

allows the uncoupling of the gears in a rapid and easy way through a key

supplied with the operator.

The limit switch is of mechanical type.

The electronic managing equipment together with the

encoder

(optional fitting

purchasable separately) keeps control on all the functions of the automation

system and on the reversing of the movement in case of obstacle.

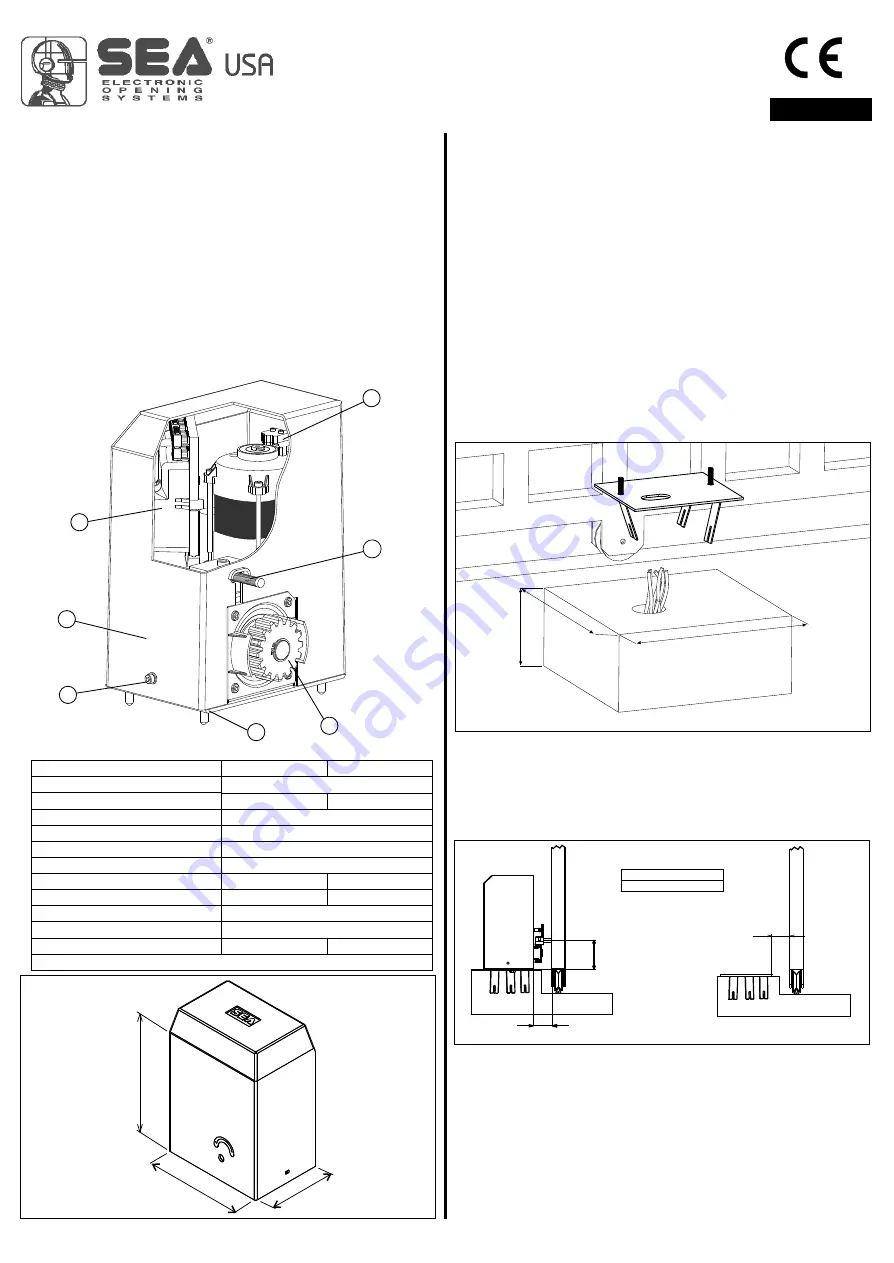

1

Mounting plate

2

Pinion

3

Mechanical limit switch

4

Encoder

TECHNICAL DATA

Power supply

Power

Motor rotation speed

Reduction ratio

Room temperature

Thermal protection intervention

Weight of the unit

Capacitor

Protection rating

Gate speed

Maximum weight of the gate

Mechanical limit switch

Torg 600 Torg 800

115 V (±5%) 50/60 Hz

320 W 340 W

1450/1720 rpm

1/32

-4°F +131°F

266°F

29,7 Pound 30,8 Pound

45uF 60uF

IP44

32,8 feet/min

1323 Lbs 1764 Lbs

REV 02 - 09/2008

5

Electronic control unit

6

Carter

7

Fixing carter screw

MAIN PARTS NOMENCLATURE

1. GATE ARRANGEMENT

The first thing to check is that the gate is in good running order as follows:

a) The gate is rigid and straight and runs smoothly throughout its travel.

b) The lower track is in good order, straight and levelled.

c) The lower support wheels have sealed bearings or grease points.

d) The top guide must be manufactured and installed so that the gate is perfectly

upright.

e) Physical gate stops must be fitted to prevent the gate coming out of its guides

and track.

DIMENSIONS

Fig. 1

2. MOUNTING PLATE INSTALLATION

To install the mounting plate it is necessary to:

2.1.

Have a mounting plate manufactured to the dimensions shown in Fig. 1. The

plate will require to have concrete holding into which the foundation plate and the

anchor bolts will be walled up. It is best if the gate structure allows the plate to be

raised up from the finished level by 1,96 in. This will stop water gathering around

the operator.

5

,9

in

,6

n

10

i

1 ,8 i

3

n

TORG

12

n

i

8,

i

85

n

6,1 in

Fig. 2

1,96 - 2,16 in

2.2.

When you are concreting in the plate install any necessary cable ducts (Ø

1,38 in minimum) and cables in through the base plate. Cable ducts should have

sweep bends not elbow ones.

2.3.

When concreting in the plate check that the plate is perfectly levelled and

that the measurement of 1,96 - 2,16 in given in Fig. 2 is followed.

2,16 - 2,36 in

Q

Z16

MINIMUM QUOTA Q

4,4 in

3.

3.1.

Take the carter away unscrewing the screws placed in the two sides of the

motor reducer.

3.2.

Adjust the motor reducer height using the four supplied grains (Fig. 3)

respecting the quotes mentioned in Fig. 2. The adjusting grains can be used to

correct a previous and imperfect levelling of the foundation plate.

3.3.

Fix the motor reducer to the foundation plate with the supplied dices and

washers (Fig. 4)

FITTING OF THE UNIT

FITTING AND CONNECTION INSTRUCTIONS

3

3

4

4

1

1

7

7

2

2

5

5

6

6

ENGLISH

International registered trademark n. 2.777.971