- 1 -

MIGHTY WOLF LOOM

TM

A

ssembly

I

nstructIons

for

D

IsAssembleD

l

ooms

FL3002E

FL3004E

FL3012E

FL3014E

FL3022E

FL3024E

02.20

Find out more at

schachtspindle.com

Schacht Spindle Company 6101 Ben Place Boulder, CO 80301

p. 303.442.3212 f. 303.447.9273

© 2020 Schacht Spindle Company, Inc.

0

1

2

3

4

5

6

TOOLS REQUIRED

#2 Phillips screwdriver

slotted (flat) screwdriver

adjustable wrench or wrenches in the following sizes:

5/16", 7/16", 3/8", 1/2"

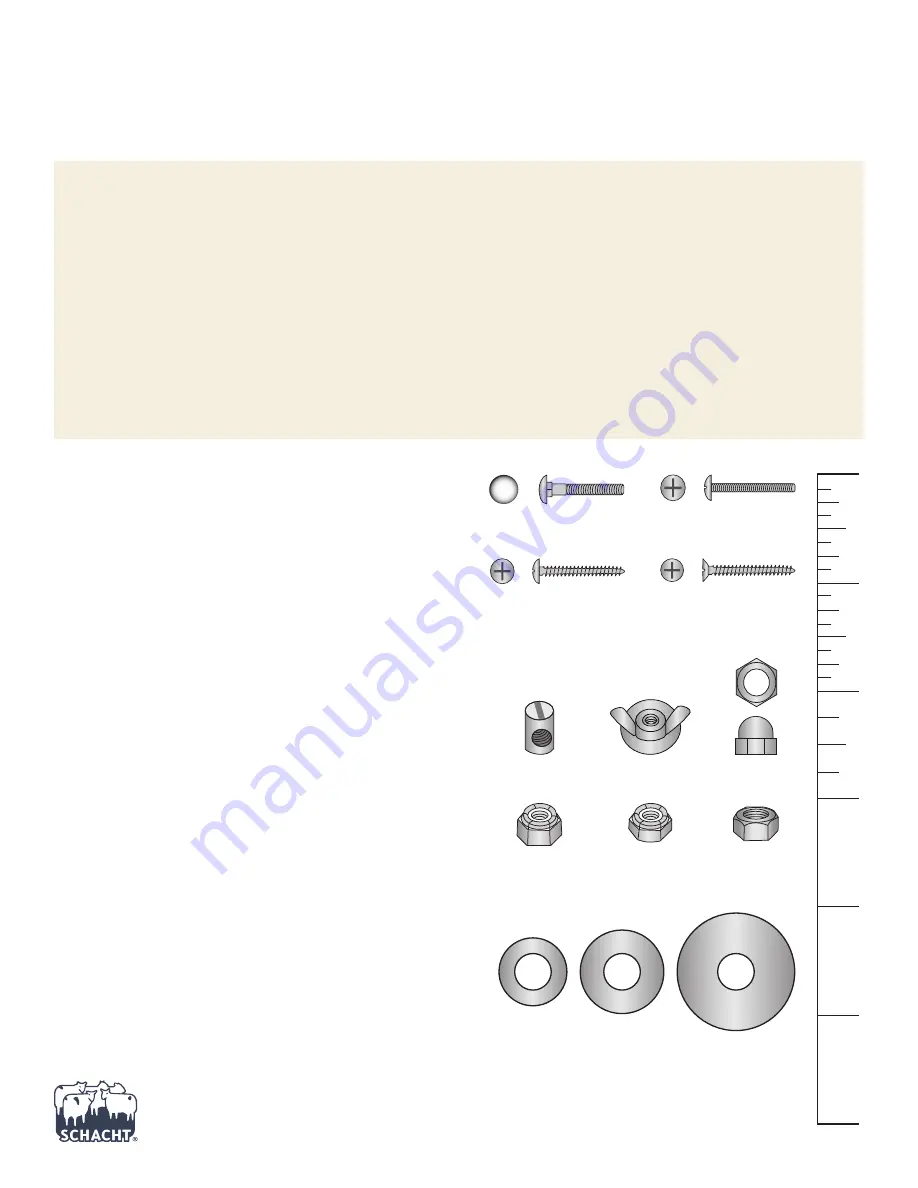

COMMON HARDWARE

These drawings are not to scale and hardware is not shown in

every size listed.

■

Screws and bolts

are sized in inches, measured by

shaft

length

. Measure the shafts of screws and bolts with a metal tape

measure or the ruler on this page. First identify all the screws and

bolts in a bag; then it will be easier to identify any nuts.

■

Nuts

attach to bolts and machine screws. They have to match

the bolt or machine screw in

diameter

and

thread size

. Match

the numbers at the beginning of the description (for instance, 10-

24 or 1/4-20) to the corresponding bolt or machine screw.

■

Washer

sizes refer to the

diameter of the hole

; measure the

hole with a metal tape measure or the ruler on this page. Different

types of washers, all the same size, are shown at right. SAE

washers have the smallest outside diameter, fender washers have

the largest outside diameter, and USS washers are in the middle.

For more help identifying hardware, see our guide at

www.schachtspindle.com/pdfs/schacht-hardware-guide.

pdf.

barrel nut

washer wing nut

cap nut

hex nut

slim lock nut

lock nut

IDENTIFYING NUTS

SAE washer

USS washer

fender washer

IDENTIFYING WASHERS

IDENTIFYING SCREWS AND BOLTS

carriage bolt

Phillips truss head

machine screw

Phillips pan head

sheet metal screw

Phillips truss head

sheet metal screw

BEFORE YOU BEGIN

■

Read through the directions before starting to assemble your

loom.

■

You’ll find a complete labelled diagram of the Wolf loom in your

Maintenance and Warranty manual and at schachtspindle.com.

■

Wolf loom legs are called out by where they cross each other.

The legs that touch the ground at the front of the loom are called

“inside” legs because they are covered by the “outside” legs when

they cross at the loom center.

■

The beater is at the front of the loom. The brake is on the right

side of loom.

■

All wooden parts of the loom have been finely sanded and

finished with hand-rubbed Danish oil. If at any time you wish

to apply more finish to the loom, use a Danish oil (tung oil and

polyurethane mixture) and hand-rub the wood with a soft lint-free

cloth.

Be sure to follow the finish manufacturer’s instructions.

■

Unpack the loom parts carefully and compare them to the

drawings on pages 4 and 5. Do not throw away the carton or any of

the packing material until you have checked to see that all of the

parts and hardware bags have been included.

■

Hardware for your loom has been packed into bags for different

steps in the assembly process.

Open each bag only when you

reach those steps, then identify the pieces included in that bag.

■

Follow the exact order of assembly. Take care and work slowly. It

will be easier to assemble your loom with a helper. Some steps may

require two people.

■

When you finish assembling the loom, go back over all of the

screws and bolts to make sure they are tight. For screws on parts

that need to pivot, tighten the screw firmly, then unscrew just

enough to allow free movement. It is a good idea to re-tighten all

screws on your loom every few months.