T

OYOTA

T

ACOMA

2014

P

ART

N

UMBER

: 250-8406 T

ACOMA

/ 250-8411 C

AMRY

R

EAR

S

IGHT

I

TEM

Q

TY

D

ESCRIPTION

1

1

I

NTERFACE

A

DAPTER

H

ARNESS

2

1

R

EAR

C

AMERA

A

SSEMBLY

3

1

C

AMERA

E

XTENSION

H

ARNESS

4

1

S

ACK

P

ARTS

N

OTE

:

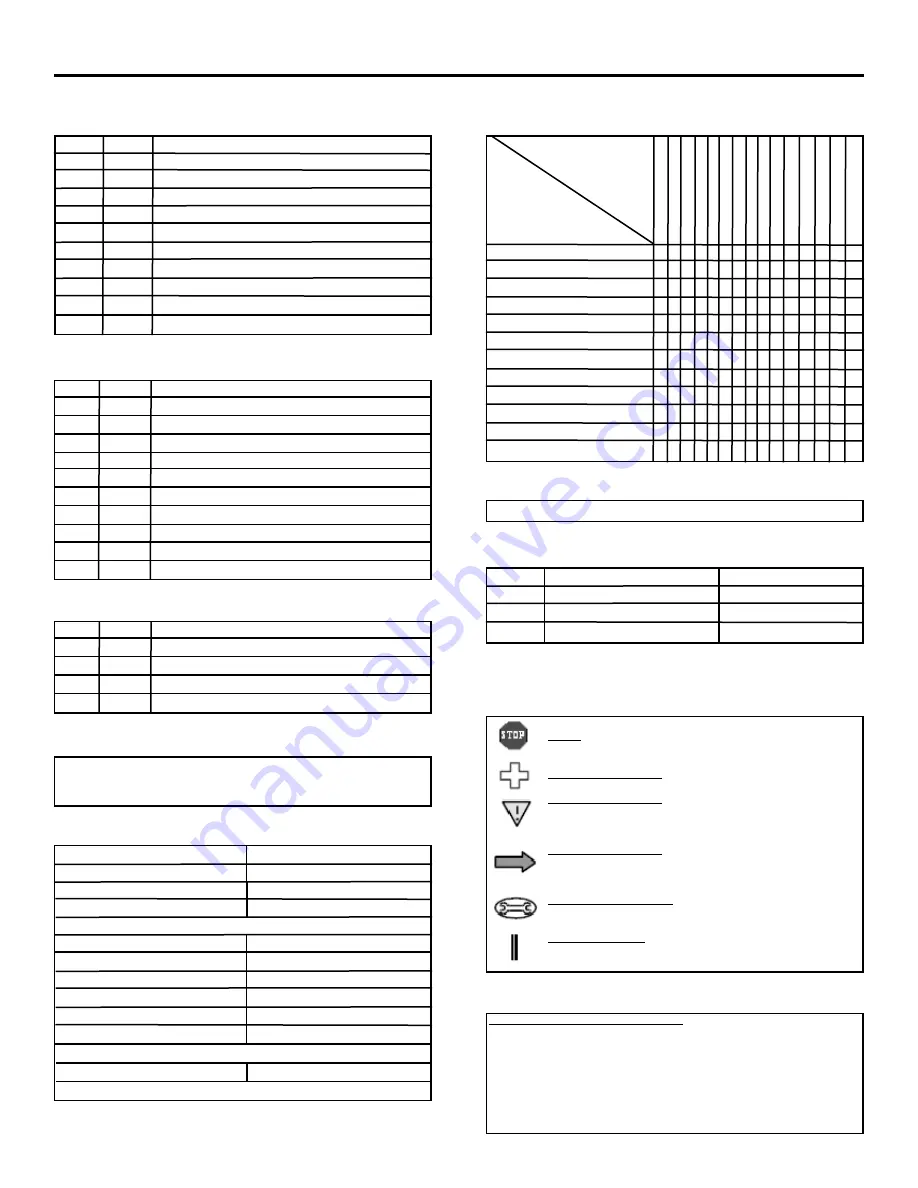

K

IT

C

ONTENTS

H

ARDWARE

B

AG

C

ONTENTS

A

DDITIONAL

I

TEMS

R

EQUIRED FOR

I

NSTALL

F

ORM

#5485 R

EV

. A 04-02-14

C

ONFLICTS

R

ECOMMENDED

T

OOLS

V

EHICLE

T

RIM

C

OLOR

C

OLOR

A

PPLICABILITY

/T

RIM

L

EVEL

A

CCESSORY

C

OLOR

A

LL

M

ODELS

G

ENERAL

A

PPLICABILITY

R

ECOMMENDED

S

EQUENCE

O

F

A

PPLICATION

L

EGEND

* M

ANDATORY

S

PECIAL

N

OTE

: I

NSTALLATION

S

EQUENCES

A

FTER

S

AFETY

MANDATED PREPATORY STEPS HAVE BEEN TAKEN

,

THE INSTALLATION

SEQUENCE IS THE SUGGESTED METHOD FOR COMPLETING THE ACCESSORY INSTAL

-

LATION

. I

N SOME INSTANCES THE SUGGESTED SEQUENCE IS WRITTEN FOR ONE

ASSOCIATE TO INSTALL AND IN OTHERS THE SEQUENCE IS GIVEN AS PART OF A TEAM

ACCESSORY INSTALLATION

. U

NLESS OTHERWISE STATED IN THE DOCUMENT

,

THE

ASSOCIATES MAY PERFORM THE INSTALLATION STEPS IN ANY ORDER TO MAKE THE

INSTALLATION AS EFFICIENT AS POSSIBLE WHILE MAINTAINING CONSISTENT QUALITY

.

STOP:

D

AMAGE TO VEHICLE MAY OCCUR

. D

O

N

OT

P

ROCEED UNTIL

PROCESS COMPLIANCE HAS BEEN MET

.

OPERATOR SAFETY:

U

SE

C

AUTION TO

A

VOID

R

ISK OF

I

NJURY

.

CRITICAL PROCESS:

P

ROCEED WITH

C

AUTION TO

E

NSURE A

Q

UALITY

I

NSTALLATION

. T

HESE POINTS WILL BE AUDITED ON A

COMPLETED VEHICLE INSTALLATION

.

GENERAL PROCESS:

T

HIS HIGHLIGHTS SPECIFIC PROCESSES TO

ENSURE A QUALITY INSTALLATION

.

THESE POINTS WILL BE AUDITED

DURING THE ACCESSORY INSTALLATION

.

TOOLS & EQUIPMENT:

T

HIS CALLS OUT THE SPECIFIC TOOLS

AND EQUIPMENT REQUIRED FOR THE PROCESS

.

REVISION MARK:

T

HIS MARK HIGHLIGHTS A CHANGE IN

INSTALLATION WITH RESPECT TO PREVIOUS ISSUE

.

I

TEM

Q

TY

D

ESCRIPTION

1

N

/

A

E

LECTRICAL

T

APE

2

3

4

S

AFETY

T

OOLS

S

PECIAL

T

OOLS

I

NSTALLATION

T

OOLS

F

ASTENER

R

EMOVAL

T

OOL

W

IRE

C

UTTERS

T

RIM

R

EMOVAL

T

OOL

T30

TORX SOCKET

10-

MM

D

EEP

S

OCKET

T

ORQUE

W

RENCH

(36

IN

.

LB

.)

S

PECIAL

C

HEMICALS

I

TEM

Q

TY

D

ESCRIPTION

1

10

W

IRE

T

IES

2

3

A

DHESIVE

F

OAM

3

1

S

EALING

P

UTTY

4 1 A

LCOHOL

P

AD

Summary of Contents for 250-8406

Page 8: ......