The Rayburn 200 G/L Cooker provides cooking facilities

only, and is suitable for Natural Gas. A single atmospheric

gas burner is thermostatically controlled at cooking rates,

and operates at a low bypass rate when idling.

The exhaust flue connection of the appliance is in Open

Flue form, operating on natural draught.

Facilities included on the cooker are, a heat graduated

hotplate, main oven and lower oven. A timing programmer

is also available, as an optional extra.

Gas connection 15mm O.D. copper

Open flue outlet 100mm (4in. int)

Electric Supply 240V ~ 50Hz 3 amp fused

Weight of Appliance 275kg

Installation Instructions

The appliance must be installed in accordance with these

instructions, local gas fitting regulations, municipal

building codes, electrical wiring regulations, the AGA Gas

Installation Code and any other relevant statutory body.

In your own interests, and that of safety to comply with the

law, all gas appliances to be installed by authorised

persons, in accordance with the above regulations.

Failure to install appliances correctly could lead to

prosecution.

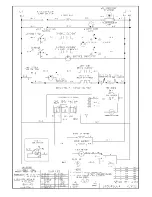

Installation and Servicing Instructions

for Rayburn 200G/L

Gas Fired Cooker

AUSTRALIAN MARKET

Certificate of Approval No. 5013

1

01/10 EINS 512070

INTRODUCTION

INSTALLATION INSTRUCTIONS

Technical Specification

Natural Gas

Heat Input

5.6kW

Pressure

G20

20mbar

G25

25mbar

Injector Size

1.82 Bray 460

Pilot Size

38/36A

Propane

Heat Input

20MJ/h

Inlet Pressure

Propane 2.75 kPa

Injector Size

1.27 Bray 220

Pilot Size

4209

IMPORTANT NOTICE:

Any alteration that is not approved by AGA,

could invalidate the approval of the appliance, the operation of the

warranty and could also affect your statutory rights.

Control of Substances - Health and Safety

Important

This appliance may contain some of the materials that are indicated

below. It is the Users/Installers responsibility to ensure that the

necessary personal protective clothing is worn when handling, where

applicable, the pertinent parts that contain any of the listed materials

that could be interpreted as being injurious to health and safety, see

below for information.

Firebricks, Fluebeds, Artificial Fuels –

when handling use

disposable gloves.

Fire cement –

when handling use disposable gloves.

Glues and sealants –

exercise caution – if these are still in liquid

form use face mask and disposable gloves.

Glass Yarn, Mineral Wool, Insulation Pads, Ceramic Fibre,

Kerosene Oil –

may be harmful if inhaled. may be irritating to skin,

eyes, nose and throat. When handling avoid, inhaling and contact

with skin or eyes. Use disposable gloves, face-masks and eye

protection. After handling wash hands and other exposed parts.

When disposing of the product, reduce dust with water spray, ensure

that parts are securely wrapped.