1055 Mendell Davis Drive, Jackson, MS 39272

888-994-7636, fax 888-266-5244

Information contained in this document is known to be current and accurate at the time

of printing/creation. Unified Brands recommends referencing our product line websites,

unifiedbrands.net, for the most updated product information and specifications.

Custom

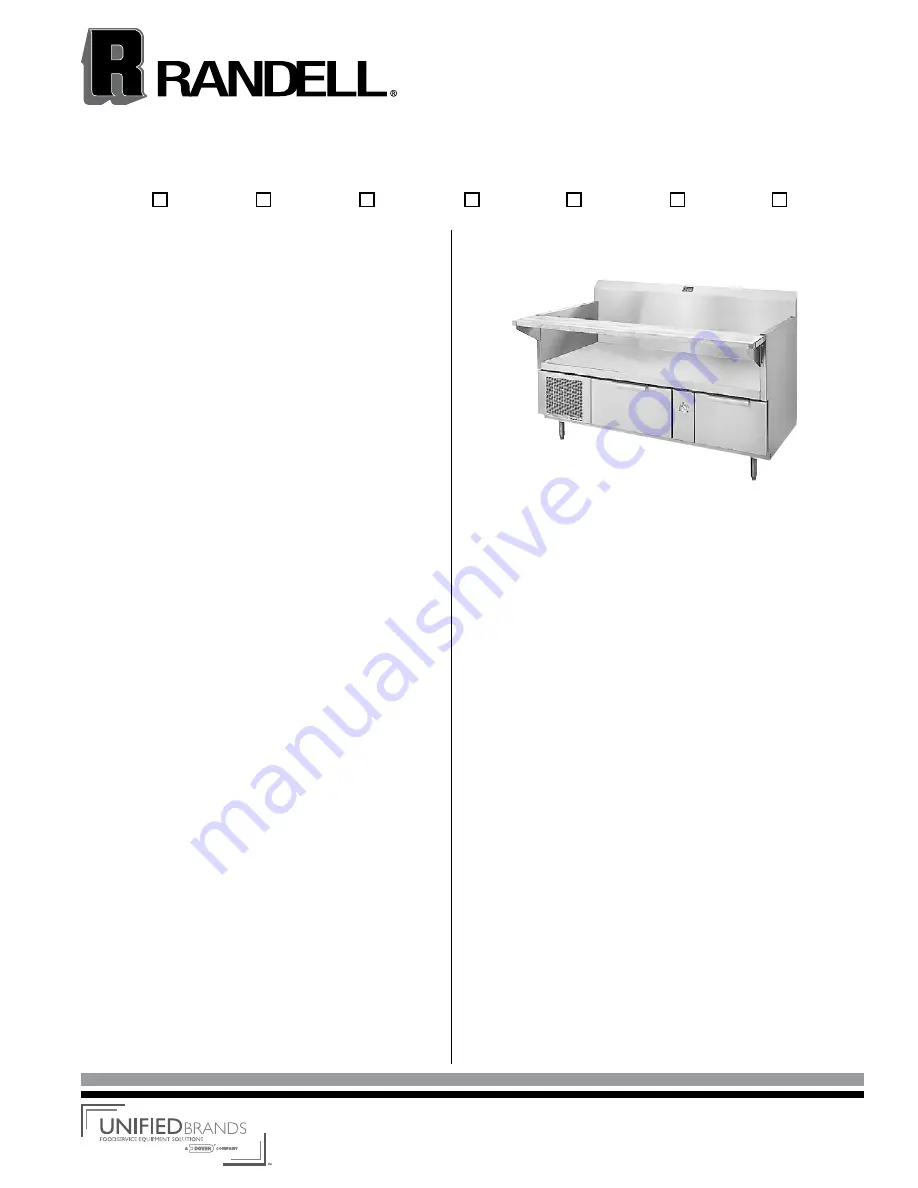

SC Refrigerated Equipment Stand

models 25000A

Description:

Self-contained, CFC free, refrigerated cooking equipment

stand with reinforced stainless steel equipment shelf. Integral

backsplash with 45˚ return. Refrigerated drawers on 16 gauge

stainless steel tracks with 1 5/8" stainless steel bearings and

removable plastic pan. 6" high adjustable legs.

Shown with optional finished end.

Standard Features:

• Available under one piece top with other modular equipment up

to 16' in length

• 6" high legs—adjustable and movable

• 10" wide x 1 1/4" thick laminated maple work board

• Self-closing drawers with removable plastic pan

• Self-contained refrigeration system features expansion valve

for fast recovery, and thermostatic control for field

adjustability, R-134a refrigerant, CFC free

• If unit is fitted with vent, then backsplash will be 3" thick to

meet NFPA 96

• 45˚ integral stainless backsplash is standard. 90˚ stainless

steel backsplash is optional.

• Equipment Rails are optional

Specifications:

EQUIPMENT SHELF: Equipment shelf to be one piece of die-

formed stainless steel with 2" nosing and marine edge. Shelf is

reinforced with welded channel brace assembly.

UNIT BODY: Body ends to be die-formed stainless steel, finished

and polished on the inside, with corrosion resistant exterior. Ends

at top fitted with recessed heavy duty steel bars for splining units

together, producing a hairline seam. Backsplash to be coved

cornered, with 45˚ return at top and overall height of 6 3/4".

(If fitted with vent system, standard backsplash to be omitted

and unit fitted with 3" thick backsplash to meet NFPA 96). 10"

wide x 1 1/4" thick laminated maple cutting board provided

with removable supports. Base interior to be ABS thermoplastic

at ends only. Stainless steel interior liner to be coved cornered

to form bottom, back and top. Unit insulated with CFC free,

high density polyurethane expanding foam. Legs to be 6" high

stainless steel, with adjustable bullet foot. Legs mounted to full

length channel frame assembly which is integrally welded to

bottom of assembly. Legs can be moved left to right to avoid

floor obstacles during installation.

DRAWERS: Self-contained refrigerated drawers are located below

equipment shelf. Drawer liners are plastic, removable without

tools, with drawer tracks of 16 gauge stainless steel with 1 5/8"

stainless steel bearings, self-closing. Drawer opening frame to be

ABS and contain magnetic strip for positive sealing of gaskets.

Drawer fronts to be 22 gauge stainless steel with 16 gauge

stainless steel handles, magnetic gaskets, and plastic pan.

REFRIGERATION: Interior fitted with Randell R-134a evaporator

blower coil for cooling base. Blower coil fitted with expansion valve

for fast recovery and thermostatic control for field adjustability.

Condensing unit sized and installed for proper cooling. Units

totally prewired and to be supplied with 8' cordset (NEMA 5-

15P) for 115 volt operation. Hot gas condensate evaporator to be

installed in compressor airflow.

Randell Custom, Page 8

Revised 08/05

model

25348A

25366A

25378A

25384A

25396A

253102A

253114A