INSTALLATION INSTRUCTION -

NAIL FIN INSTALLATION AFTER WEATHER BARRIER AND

FRAME SCREW OR CLIP INSTALLATION FOR REPLACEMENT

ALUMINUM-CLAD EXTERIOR HINGED PATIO DOORS (PELLA® PROLINE AND DESIGNER SERIES®)

ALUMINUM-CLAD EXTERIOR ENTRY DOORS (PELLA® AND ARCHITECT SERIES®)

Part Number: 81AK0101

© 2011 Pella Corporation

Important Safety Information:

These instructions were developed and tested for use with typical wood frame wall construction

in a wall system designed to manage water.

These instructions are not to be used with any

other construction method.

Installation instructions for use with other construction methods,

multiple units or bow and bay windows, may be obtained from Pella Corporation, a local Pella

retailer or by visiting

http://www.pella.com

. Building designs, construction methods, building

materials, and site conditions unique to your project may require an installation method

different from these instructions and additional care. Determining the appropriate installation

method is the responsibility of you, your architect or construction professional.

REMEMBER TO USE APPROPRIATE PERSONAL PROTECTIVE EQUIPMENT.

Always read the Pella

®

Limited Warranty before purchasing or installing Pella

products. By installing this product, you are acknowledging that this Limited

Warranty is part of the terms of the sale. Failure to comply with all Pella installation

and maintenance instructions may void your Pella product warranty. See Limited Warranty for

complete details at

http://warranty.pella.com.

Please read thoroughly and understand completely all the steps in this instruction prior to

beginning installation.

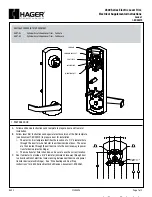

Installation with Nail Fin follow steps 1, 2, 3, 4, 6, 7

Replacement Installation Without Nail Fin

follow steps 1, 2, 3, 5, 6, 7