CCBB Series Floor Box

I N S T A L L A T I O N I N S T R U C T I O N S

Installation Instruction No.: 1 009 489R2 – Updated May 2012

Legrand/Wiremold electrical systems conform to and should be

properly grounded in compliance with requirements of the current

National Electrical Code or codes administered by local authorities.

All electrical products may present a possible shock or fire

hazard if improperly installed or used. Legrand/Wiremold electrical

products may bear the mark as UL Listed and/or Classified and

should be installed in conformance with current local and/or the

National Electrical Code.

Products Covered: CCBBS, CCBBS-OG, CCBBSCTCAL, CCBBSBTCAL

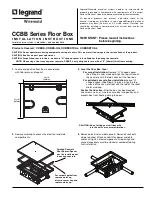

1.

Locate and position floor box in accordance

with floor plans or blueprint.

4.

Remove electrical and data panels. Remove knockouts

where required. Attach conduits for power and data

cables using UL Listed components. All openings and

unused knockouts must be closed or sealed off during

final installation.

2. Level the floor Box, then:

For carpet installation:

Remove “U” shaped spacer

(See Step 3) under mudcap. Align the top surface of

the concrete with the top surface of the floor box.

For polished concrete floor installation:

Leave “U”

shaped spacer (See Step 3) in place. Align the top

surface of the concrete floor with the top of the sheet

metal mud cap.

Anchor the floor box:

After the box has been leveled,

use screws, nails, or wire to secure box into position and

prevent box from floating during the pour.

IMPORTANT: Please read all instructions

before beginning.

CAUTION: Do not operate resurfacing equipment over top of covers. This may result in damage to the surface finish of the product.

CAUTION: Box has no post pour adjustment.

CAUTION: For polished concrete floors, make sure “U” shaped spacer is installed prior to pouring the concrete.

NOTE: When using a floor covering over concrete, CCBBS is only designed for use with a 1/4" [6.4mm] thick floor covering.

CAUTION: Do not dislodge or shift box with

job site traffic or concrete vibrations.

19 1/8"

[486mm]

15 1/4"

[387mm]

3.

Remove mudcap to access the electrical and data

compartments.

For carpet applications

remove mud cap,

discard spacer ring and

replace mud cap.

Polished Concrete

Floor Spacer: Spacer

must be installed prior

to pouring concrete.