Revision 1.3

P/N 119-042

9 January 2008

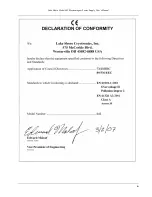

Lake Shore Cryotronics, Inc.

575 McCorkle Blvd.

Westerville, Ohio 43082-8888 USA

E-mail Addresses:

[email protected]

[email protected]

Visit Our Website At:

www.lakeshore.com

Fax: (614) 891-1392

Telephone: (614) 891-2243

Methods and apparatus disclosed and described herein have been developed solely on company funds of Lake Shore Cryotronics, Inc. No government

or other contractual support or relationship whatsoever has existed which in any way affects or mitigates proprietary rights of Lake Shore Cryotronics,

Inc. in these developments. Methods and apparatus disclosed herein may be subject to U.S. Patents existing or applied for. Lake Shore Cryotronics,

Inc. reserves the right to add, improve, modify, or withdraw functions, design modifications, or products at any time without notice. Lake Shore shall

not be liable for errors contained herein or for incidental or consequential damages in connection with furnishing, performance, or use of this material.

User’s Manual

Model 642

Electromagnet

Power Supply