02

Features

• Designed to withstand extreme levels of use at its highest peak performance.

• Complete new CNC cut motor case with extra front spoke ventilation slots.

• Works as a sensored unit and also sensorless without the sensor cable attached.

• Selectable mechanical timing of 30 to 60 degrees for STOCK motors (*10.5-25.5T) and 20 to

50 degrees for non-STOCK motors (*3.5-8.5T).

• Minimal maintenance is required with precise machining technology which ensures a

minimum tolerance end play of the rotor shaft. Eliminating the copper shims used in most of

today’s motors.

• 200

℃

high temperature tolerance and high purity copper windings maximize conductivity

and reliability.

• 200

℃

high temperature tolerance sintered NdFeb (Neodymium, 35EH-LT) magnets.

• Extreme low resistance multi-layered outlet PCB and high RPM NSK bearings.

• Compliant with ROAR, IFMAR, BRCA and JMRCA rules, certificated by RoHS, CE, FCC etc.

04

INSTALLATION AND CONNECTIONS

• Install the motor in its mount using M3 screws no longer than 8mm.

• There are 3 power wires coming from the ESC must be soldered to the motor.

They are usually color coded as Blue for Wire A, Yellow for Wire B and Orange

for Wire C. When connecting the power wires between the ESC and motor,

please make sure that you match ESC Wire A to Motor Phase A, ESC Wire B to

Motor Phase B and ESC wire C to Motor Phase C (This is VERY important).

• When using sensored ESC, make sure the sensor cable is clean and reliable.

Connect the sensor cable to both ESC and motor in the correct direction.

• Double check you have all the connections correct before turning on the ESC

(See connection diagram as below).

Sensor wire

Blue power wire

(motor phase “A”)

Yellow power wire

(motor phase “B”)

Orange power wire

(motor phase “C”)

Switch

ESC

Input TH

Channel

(Ch.2)

Receiver

Servo

Battery Positive (Red)

Battery Negative (Black)

- + S

01

CAUTIONS

CAUTIONS

ATTENTION

USER MANUAL

V10 G2

05

TIMING ADJUSTMENT

• To adjust the timing, simply loosen the 1 short screws on the back of the motor and rotate the Sensor Module Cover, noting the white-color lines

on the motor and the mark (pointer) on the cover. After the adjustment, please lock the 2 short screws.

• You can alter the timing on the motor to change the power-band and characteristics of the motor for best and the most efficient performance.

The factory timing for STOCK motors (*10.5-25.5T) is 40 degrees, for non-STOCK motors (*3.5-8.5T) is 30 degrees. You can reduce the timing by

turning the end cap clockwise, increase the timing by turning the end cap counter clockwise.

• Increasing the timing will increase the RPM of the motor whilst at the same time increasing temperatures and losing efficiency. Higher timing will

require a softer gear ratio. We recommend you start with this setting and adjust based on your needs from that position.

• When setting your motor timing it is important to make sure your ESC is also set correctly. Please follow your ESC instructions on how to do this.

To check the motor temperatures during testing, simply drive for 3 laps of the track, stop and use an infrared temperature measuring instrument

to make sure the motor is not too hot. If the motor is too hot then allow the motor to cool before trying it again.

OPTIONS

30820001

30820002

30820005

30820006

30820007

30820008

30820009

30820012

30820013

30820014

30820015

XERUN-V10-Rotor-

Φ

5-12.3

XERUN-V10-Rotor-

Φ

5-12.5F

XERUN-V10-Rotor-

Φ

5-12.5

XERUN-V10-Rotor-

Φ

7-12.5

XERUN-V10-Rotor-

Φ

5-13.0

XERUN-V10-Rotor-

Φ

5-13.5

XERUN-V10/Bandit-Rotor-

Φ

5-12.1

XERUN-V10-Rotor-

Φ

5-12.5-U-T

XERUN-V10-Rotor-

Φ

7-12.3-U

XERUN-V10-Rotor-

Φ

7-12.5-U

PN

Spare Part

Description

Specification

Ball bearing

540 MOTOR BEARING-3.175

R2ZZ Ball Bearing, 3.175x9.525x3.967mm

Thick magnet, w/o cooling fan, magnet hole Ø5, O.D. of the magnet:12.3mm

Thick magnet, with cooling fan, magnet hole Ø5, O.D. of the magnet:12.5mm

Thick magnet, w/o cooling fan, magnet hole Ø5, O.D. of the magnet:12.5mm

Thin magnet, w/o cooling fan, magnet hole Ø7, O.D. of the magnet:12.5mm

Thick magnet, w/o cooling fan, magnet hole Ø5, O.D. of the magnet:13.0mm

Thick magnet, w/o cooling fan, magnet hole Ø5, O.D. of the magnet:13.5mm

Thick magnet, w/o cooling fan, magnet hole Ø5, O.D. of the magnet:12.1mm

Thick magnet / titanium-alloy shaft, w/o cooling fan, magnet hole Ø5, O.D. of the magnet:12.5mm

Thin magnet / strong magnet, w/o cooling fan, magnet hole Ø7, O.D. of the magnet:12.3mm

Thin magnet / strong magnet, w/o cooling fan, magnet hole Ø7, O.D. of the magnet:12.5mm

Rotor

09

• The “Max. Output Power” is measured with 7.4V input voltage and ESC at ZERO timing. This parameter is neither the “maximum input power” nor the “rating power”, it is calculated

by “RPM x Torque / 9550”. Because each factory runs a different testing platform, the above data may vary if the motor is tested in different factories running different testing platforms.

Attention: The “Output Power” value shouldn’t be compared with the “Input Power” value directly because the motor efficiency is always less than 100%, the value of

“Output Power” is always smaller than the “Input Power” .

• The “Current at Peak Output Power” is a guide used for selecting the suitable power system (ESC, Motor, Gear ratio, etc.) If the actual input current of the power system is bigger than

the peak parameter stated in the above table, this means that the power system settings/configuration is over its peak (Or in other words, “overloaded”)

• The “KV” is measured without any load on the motor and ESC at ZERO timing. Please don’t run the motor without load for long periods of time (1 minute), otherwise the motor may

overheat.

03

SPECIFICATIONS

30401100

30101101

30101102

30101103

30101104

30101105

30101106

30101107

30401108

30101109

30401101

9550KV

0.002

Ω

8.4A

600W

120A

7600KV

0.0032

Ω

6.6A

500W

115A

5800KV

0.0045

Ω

6.5A

470W

110A

5000KV

0.0062

Ω

5.5A

430W

105A

4550KV

0.0088

Ω

3.8A

380W

97A

4050KV

0.0106

Ω

3.2A

360W

90A

3800KV

0.0163

Ω

2.1A

260W

74A

3000KV

0.0265

Ω

1.8A

220W

59A

2300KV

0.0457

Ω

1.3A

150W

41A

1900KV

0.072

Ω

1.1A

120W

32A

PN

Φ

5-12.3

Φ

5-13.0

Φ

5-12.5

Φ

7-12.5-U

Φ

7-12.3-U

KV

Without Load

(RPM/V)

Resistance

Current

Without

Load

Max.

Output

Power

Current

@Max.

Output

Power

Dia. & Length

Dia. of

External

Shaft

Stock

Rotor

Application

1/10 on-road Modified;1/10 4WD off-road Modified

1/10 4WD off-road Modified

1/10 Drift; 1/10 on-road Stock

1/10 Stock;1/10 rock crawler

1/10, 1/12 on-road Modified

1/10 on-road Stock

1/10 Drift; 1/10 2WD off-road Modified

3.5T

4.5T

5.5T

6.5T

7.5T

8.5T

10.5T

13.5T

17.5T

21.5T

Model

25.5T

1500KV

0.0531

Ω

0.8A

85W

24A

Weight

Ø=36mm

(1.417in)

L=52.5mm

(2.067in)

Ø=3.17mm

(0.125in)

L=15mm

(0.575in)

178g (6.279oz)

178g (6.279oz)

181g (6.385oz)

181g (6.385oz)

172g (6.067oz)

178g (6.279oz)

170g (5.997oz)

172g (6.067oz)

173g (6.102oz)

170g (5.997oz)

166g (5.855oz)

GEARING

06

3.5T

4.5T

5.5T

6.5T

7.5T

8.5T

10.5T

13.5T

17.5T

21.5T

11.0:1

9.5:1

8.5:1

8.0:1

7.6:1

7.0:1

5.5:1

4.7:1

4.0:1

3.5:1

25.5T

3.2:1

2.7:1

66mm

5.2:1

5.2:1

6.2:1

10.5:1

8.5:1

7.5:1

7.0:1

6.6:1

6.3:1

5.0:1

4.0:1

3.5:1

3.0:1

25mm

29mm

32mm

35mm

36mm

38mm

42mm

51mm

66mm

66mm

11.1:1

10.3:1

9.4:1

8.5:1

8.0:1

7.0:1

6.0:1

5.5:1

12.0:1

10.8:1

9.8:1

8.9:1

8.0:1

7.0:1

6.0:1

5.5:1

13.5:1

12.6:1

11.5:1

10.4:1

9.0:1

8.0:1

7.0:1

6.5:1

1/10 on-road (Small track)

1/10 on-road (Big track)

1/12 on-road

2WD off-road

4WD off-road

Truggy

Class

Not Available

7.4V LiPo

7.4V LiPo

3.7V LiPo

7.4V LiPo

7.4V LiPo

7.4V LiPo

Battery

Below is a very rough idea of starting gear ratios for the motors. Please be aware that these are guide ratios for ESC with ZERO timing. Please always check with other drivers using the

same ESC/Motor combination at your track for a good starting point. If you have no idea about what gear ratio is most suitable for your car, please begin with “softer” gearing and then

adjust as needed.

Thanks for purchasing Hobbywing Xerun V10 Sensored Competition Motor. High

power motor can be very dangerous, so please read through this manual carefully.

Given that we have no control over the correct use, installation, application, or

maintenance of our products, no liability shall be assumed nor accepted for any

damages, losses or costs resulting from the use of the product.

Any claims arising from the operating, failure or malfunctioning etc. will be

denied. We assume no liability for personal injury and/or consequential damages

resulting from our product or our workmanship. As far as is legally permitted, the

obligation to compensation is limited to the invoice amount of the affected

product.

We, HOBBYWING, are only responsible for our product cost and nothing else as

result of using our product.

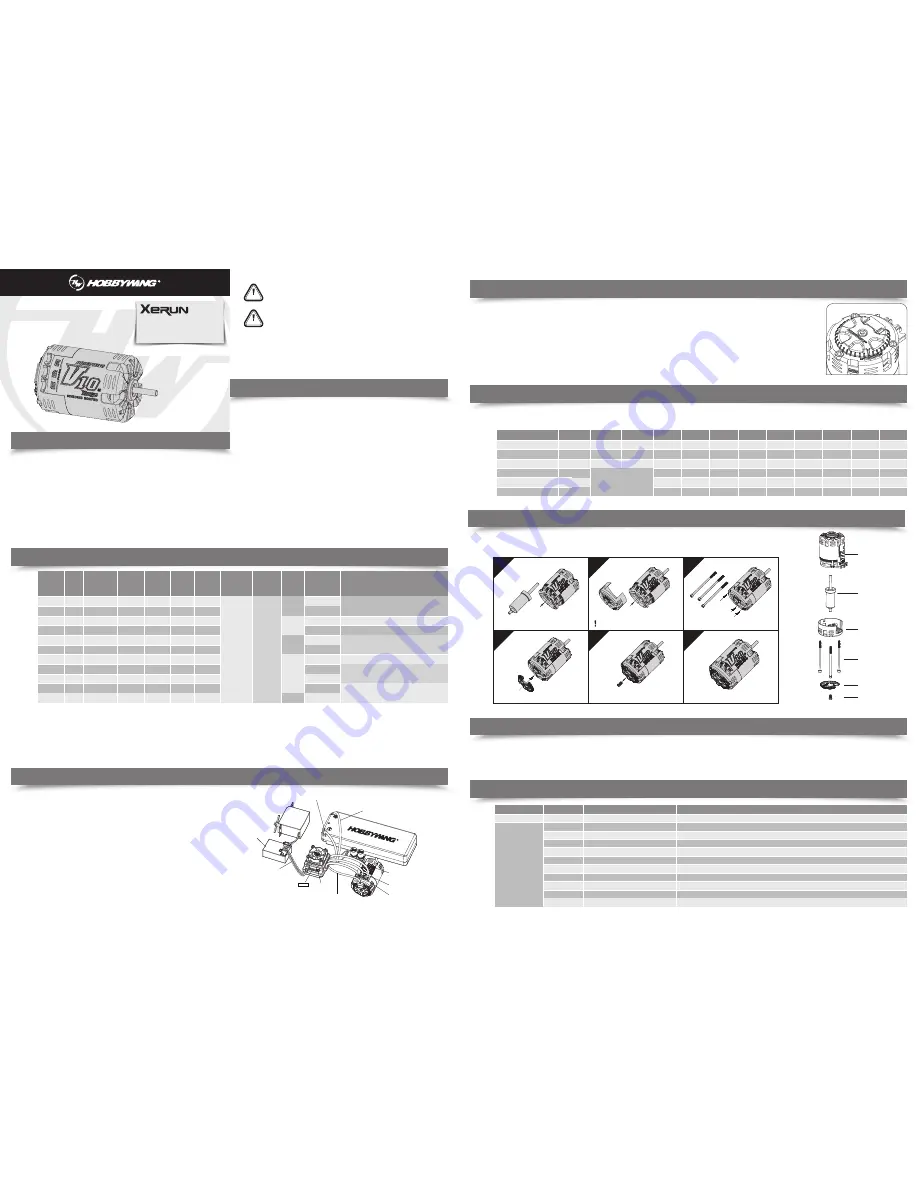

PARTS LIST

08

The XERUN V10 G2 Motor has the parts as below (Please also check picture 5 for reference).

1) Ball bearing x 1 (13.175x9.525x3.967mm)

2) Rotor x 1

3)Front casing x 1

4) Metal Bottom Case (w/ Sensor Module) x 1 5) Long screws x 3 (M2.50x45mm)

6) Cover of sensor module x 1

7)Short screws 1 (M2.50x6.0mm) 8) Sensor wires x 2 (80mm, 200mm)

• Avoid incorrect connections between the electronic speed controller (ESC) and the

motor.

• All wires and connections should be well insulated. Short-circuits can possibly damage

the products.

• Never allow this product or other electronic components to come in contact with

water, oil, fuel or other electro-conductive liquids. If this happens, stop the use of

your product immediately and let it dry carefully.

• Avoid overloading the motor due to wrong or too aggressive gear ratios. Different

ESCs have different internal timings, follow the ESC instructions.

• Never apply full throttle if the pinion is not installed. Due to the extremely high RPMs

without load, the motor can get damaged.

• Always wire up all the parts of the equipment carefully. If any of the connections

come loose as a result of vibration, your model RC may lose control.

• Avoid soldering longer than 5 seconds at each soldering joint when replacing the

power wires to prevent possible damage to the product due to overheating of the

components. Use a high power soldering station with at least 60W for soldering.

• Never allow the motor case to get over 100 degrees Celsius (212 degrees Fareheit)

because the magnets maybe demagnetized by high temperature.

20170110

07

The XERUN V10 G2 Motor is very strong in construction but also easy to disassemble for maintenance.

We recommend periodical checking of the bearings and to clean the motor of dirt.

Please follow the steps in below to assemble the motor. When disassembling the motor, the sequences are reversed.

ASSEMBLY AND DISASSEMBLY

Rotor x1

Front casing x1

Bottom casing x1

Long screws x3

M2.50 x 45mm

Sensor module

cover x1

Short screws x1

M2.50 x 6.0mm

4. Install the cover of sensor module

5. Tighten the screws to lock the cover of

sensor module

6. Motor assembled

1. Install the rotor

3. Install the long srews

2. Install the bottom casing

*The bulge on the sensor module should

aim at the notch on the bottom casing.

1

2

3

4

5

6