A Unit of

Corporation

ISO 9001 &14001 CERTIFIED

1

Life

LINEAR

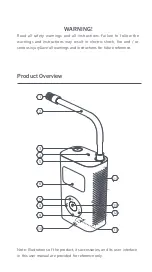

OILLESS COMPRESSORS

OPERATION & MAINTENANCE MANUAL

PART NO. 70-1570 F1-210 (REV. F)

Product Use Criteria

Depends upon speed, operating pressure and motor maintenance

• Pump only clean, dry air.

• Operate at 40ºF - 104ºF (4.4ºC - 40ºC)

• Protect unit from dirt and moisture.

• Do not pump flammable or explosive gases or use in an atmosphere that contains

such gases.

• Corrosive gases and particulate material will damage unit. Water vapor, oil-based

contaminants or other liquids must be filtered out.

• Oil-less compressors require NO lubrication

• Consult your Gast Distributor/Representative before using at high altitudes.

www.gastmfg.com

䊛

Registered Trademark/

姠

Trademark of Gast Manufacturing Inc., Copyright

䊚

2002 Gast Manufacturing Inc. All Rights Reserved.

PLEASE READ THIS MANUAL COMPLETELY

BEFORE INSTALLING AND USING THIS MOTOR.

SAVE THIS MANUAL FOR FUTURE REFERENCE

AND KEEP IN THE VICINITY OF THE MOTOR.

Thank you for purchasing this Gast product.

It is manufactured to the highest standards using quality materials.

Please follow all recommended maintenance, operational and safety

instructions and you will receive years of trouble-free service.

DDL15

DBM40-DBM80

DBMX100