X7503205500

X750008780

12/05

Chain Saw

Instruction Manual

MODELS :

CS-305

CS-306

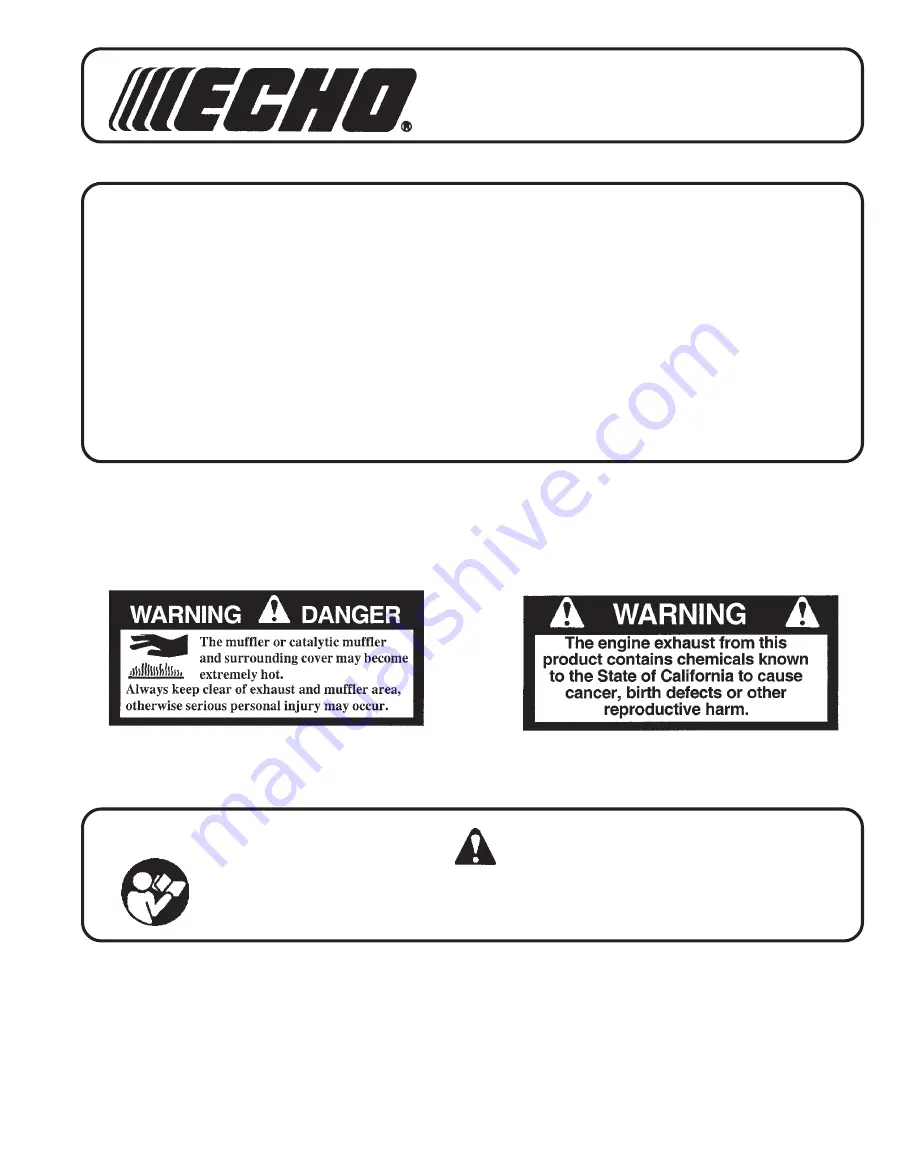

WARNING

DANGER

Read rules for safe operation and instructions carefully. ECHO provides an Instruction

Manual and a Safety Manual. Both must be read and understood for proper and safe

operation.