779 Washington St., Buffalo, N.Y. 14203-1396 U.S.A. • (716)856-2200 • Fax (716)856-1140 or (716)856-2068

Manufacturers of Eastman Cloth Cutting and Cloth Spreading Machines

Website: www.EastmanCuts.com

Form E-551

Technical Support:

1-800-872-5595

WARNING

This machine is equipped with a very sharp

knife. Keep hands, arms, and hair away from

the knife area at all times.

Misuse of this machine or failure to follow all

safety instructions on this machine and in the

instruction manual may result in serious

personal injuries.

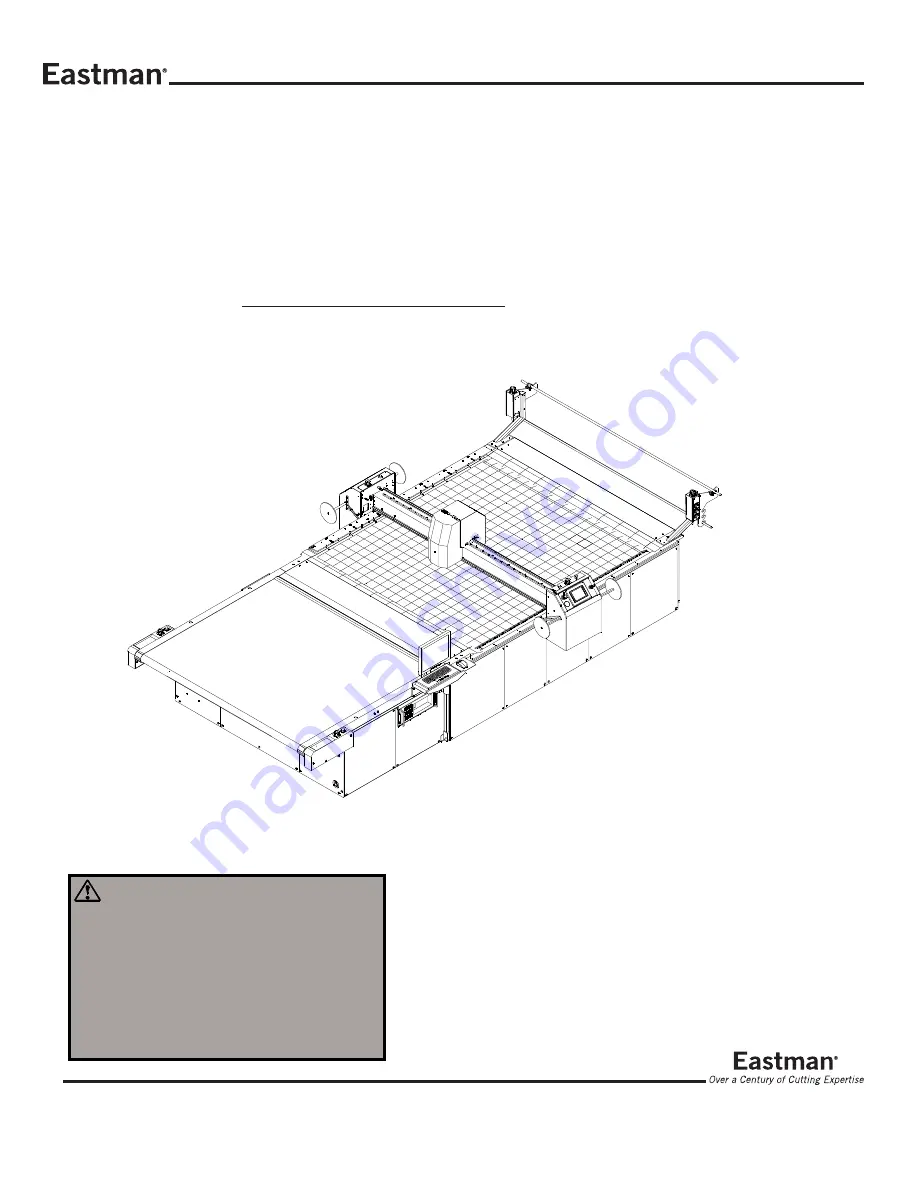

THE EASTMAN

®

Multi-Ply

Automatic Cutting System

Model: MPC 5000

Service Manual