BURR KING MFG. CO., INC

1220 Tamara Lane

Warsaw, MO 65355

www.burrking.com

(660)438-8998 • Fax (660)438-8991

B

URR

K

ING

M

ODEL

1001

D

EBURRING

& P

OLISHING

L

ATHE

M

ODEL

1001

I

NSTRUCTION

M

ANUAL

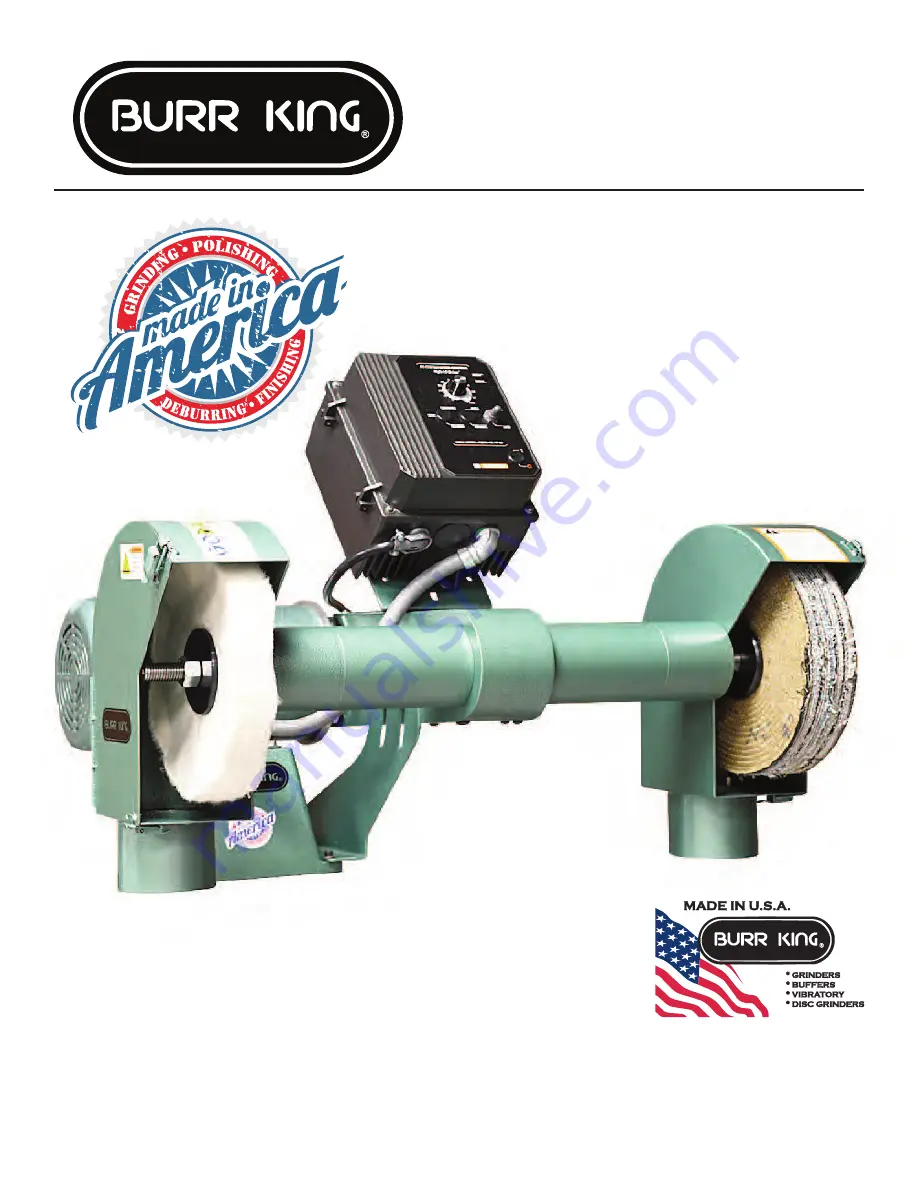

Model 11011 shown with optional

dust scoop kits and wheels