1 of 6

AvalonN Add a Plate

Configure AvalonN and Apogee Prepress for a new plate size

Follow these steps to add and configure a new plate size for use with the AvalonN platesetter

and Apogee Prepress.

Audience: Customer, Technical

Product: Apogee Prepress, AvalonN

Add the plate to the AvalonN engine

At the AvalonN engine press Offline, press Set plate and OK. Click on the next available plate and OK.

PT-R8300/PT-R8600 USERS MANUAL

4-8

4.4 Online mode

After turning on the power and initialization is complete, the PT-R enters online mode

and the online (Ready) screen. During online mode, image data is received from the

host computer and plate exposures are carried out.

Ready

1: Plate 1

OFFLINE

OPEN

Plates are loaded manually and ex posed. Use the information shown below to set

the plates.

“4.4.1 Manually setting a plate on exposure request from the host computer”

“4.4.2 Load plate before an exposure instruction comes from the host computer”

“4.4.3 Set next plate while exposure is in progress”

4.4.1 Manually setting a plate on exposure request from the host computer

This is the normal procedure for exposure.

1) Send the command to begin exposure from the host computer. The PT-R opera-

tion panel will show the following screen and the buzzer will beep repeatedly.

OK

Set plate listed below and close door.

No. 1 A4-8page

2) Press [OK]. The buzzer sound will stop and the following screen will appear.

CANCEL

OPEN

Set plate listed below and close door.

No. 1 A4-8page

Press [Open] button to open door.

PT-R8300/PT-R8600 USERS MANUAL

5-2

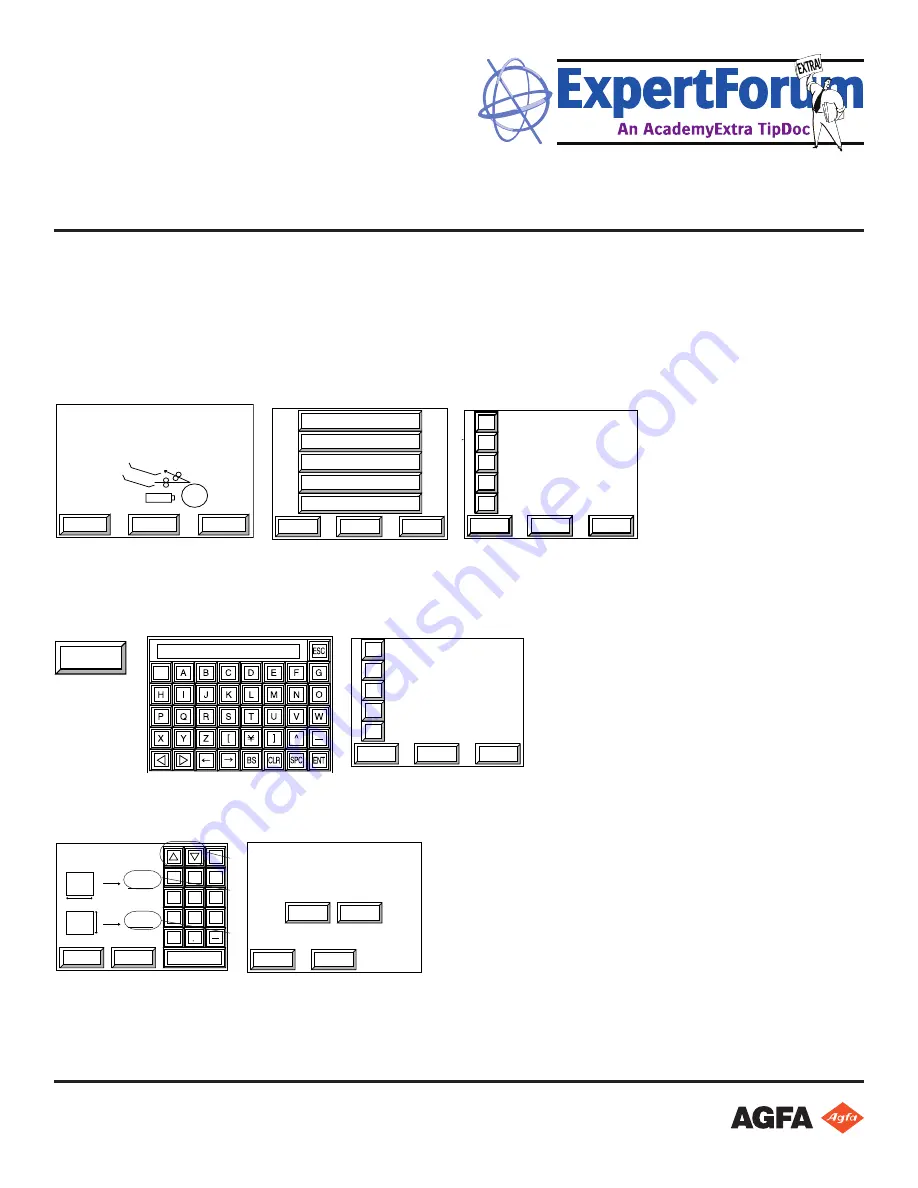

5.1 Offline mode

5.1.1 Overview of the offline mode screen

Press [OFFLINE] in the [ONLINE] screen to display the offline screen.

The offline screen hierarchy is shown below. Press [ESC] in any of these screens to

return to the previous screen. Press [ONLINE] to return to the online screen.

User maintenance

Set exposure mode

Set media type

Set plate

OK

NEXT

ONLINE

Set printing machine

Service

Set punch name

Information

OK

NEXT

ONLINE

Pressing [NEXT].

Cont. on next page

5

4

3

2

OK

NEXT

ESC

1

Plate 1

Plate 2

Plate 3

Plate 4

Plate 5

5

4

3

2

OK

NEXT

ESC

1

Printing machine 1

Printing machine 2

Printing machine 3

Printing machine 4

Printing machine 5

5

4

3

2

OK

NEXT

ESC

1

Media Type 1

Media Type 2

Media Type 3

Media Type 4

Media Type 5

Select [Set printing machine] and

press [OK].

Select [Set plate] and press [OK].

Select [Set media type] and

press [OK].

PT-R8300/PT-R8600 USERS MANUAL

5-2

5.1 Offline mode

5.1.1 Overview of the offline mode screen

Press [OFFLINE] in the [ONLINE] screen to display the offline screen.

The offline screen hierarchy is shown below. Press [ESC] in any of these screens to

return to the previous screen. Press [ONLINE] to return to the online screen.

User maintenance

Set exposure mode

Set media type

Set plate

OK

NEXT

ONLINE

Set printing machine

Service

Set punch name

Information

OK

NEXT

ONLINE

Pressing [NEXT].

Cont. on next page

5

4

3

2

OK

NEXT

ESC

1

Plate 1

Plate 2

Plate 3

Plate 4

Plate 5

5

4

3

2

OK

NEXT

ESC

1

Printing machine 1

Printing machine 2

Printing machine 3

Printing machine 4

Printing machine 5

5

4

3

2

OK

NEXT

ESC

1

Media Type 1

Media Type 2

Media Type 3

Media Type 4

Media Type 5

Select [Set printing machine] and

press [OK].

Select [Set plate] and press [OK].

Select [Set media type] and

press [OK].

Click Comment. Enter the plate name using the touchpad Use the < > arrow keys to change screens of

characters. Press ENT after each new entry.

Press ENT after each new entry or the value will not be stored!

Choose a Media Type from the list.

PT-R8300/PT-R8600 USERS MANUAL

5-4

5.1.2 Description of buttons

The buttons available in the online screen, such as [NEXT] and [ESC], are described

below.

[NEXT]

If the displayed screen consists of multiple pages, the [NEXT] button is displayed.

Press the [NEXT] button to display the next page.

5

4

3

2

OK

NEXT

ESC

1

Printing machine 1

Printing machine 2

Printing machine 3

Printing machine 4

Printing machine 5

->

10

9

8

7

OK

NEXT

ESC

6

Printing machine 6

Printing machine 7

Printing machine 8

Printing machine 9

Printing machine 10

[ESC]

Press [ESC] to return to the previous screen (level up in the hierarchy).

[OK]

Press [OK] to confirm your entry and move to the next screen.

[Comment]

Press [Comment] to display the keyboard screen. Enter a comment into the icon for

the keyboard window and press [ENT]. The previous screen appears and the com-

ment inputted will be displayed under the [Comment] button.

: Switch through the entry

screens for upper case

letters, lower case letters, and

symbols/numbers.

: Move the cursor indicating the

entry position.

BS

: Delete the letter to the left of the

cursor.

CLR

: Clear the entered comment.

SPC

: Enter a space.

OK

Comment

Plate

Copy from

ESC

Printing machine 1

Plate 1

Comment

PT-R8300/PT-R8600 USERS MANUAL

5-4

5.1.2 Description of buttons

The buttons available in the online screen, such as [NEXT] and [ESC], are described

below.

[NEXT]

If the displayed screen consists of multiple pages, the [NEXT] button is displayed.

Press the [NEXT] button to display the next page.

5

4

3

2

OK

NEXT

ESC

1

Printing machine 1

Printing machine 2

Printing machine 3

Printing machine 4

Printing machine 5

->

10

9

8

7

OK

NEXT

ESC

6

Printing machine 6

Printing machine 7

Printing machine 8

Printing machine 9

Printing machine 10

[ESC]

Press [ESC] to return to the previous screen (level up in the hierarchy).

[OK]

Press [OK] to confirm your entry and move to the next screen.

[Comment]

Press [Comment] to display the keyboard screen. Enter a comment into the icon for

the keyboard window and press [ENT]. The previous screen appears and the com-

ment inputted will be displayed under the [Comment] button.

: Switch through the entry

screens for upper case

letters, lower case letters, and

symbols/numbers.

: Move the cursor indicating the

entry position.

BS

: Delete the letter to the left of the

cursor.

CLR

: Clear the entered comment.

SPC

: Enter a space.

OK

Comment

Plate

Copy from

ESC

Printing machine 1

Plate 1

Comment

5-5

Chapter 5 User menu

[Copy from]

Use this to copy data that is already registered. Press [Copy from] to display the page

containing the copy source. Press the number button for the data you want to copy

and press [OK] to copy that data and return to the previous screen.

OK

Comment

Copy from

ESC

Media Type 1

Posi

Nega

->

15

14

13

12

OK

NEXT

ESC

11

Media Type A 0.20mm

Media Type B 0.20mm

Media Type C 0.24mm

Media Type D 0.24mm

Media Type E 0.24mm

The Fine Screen window displays. Click OK to skip. In the Plate Size window, enter the correct plate size in

millimeters. Save and click Yes to save new plate data.

5-19

Chapter 5 User menu

to be used for the Normal mode and the Fine mode will be the same. (The media

type information specified in the first page will be used in both modes.) After a

number from [0] to [20] has been selected, the specified media type setting will

be used when exposure is performed in the Fine mode.

(Cont. on “5.3.3 Setting the plate size”)

5.3.3 Setting the plate size

Set the plate size. The size to be set is the total area including the print area and the

leading and trailing grip settings.

NOTE

• The maximum plate size that can be set is 1160 x 940 mm, and the minimum size is 450 x

370 mm.

SAVE

ESC

Size [mm]

830.0

645.0

CLR

7

8

9

4

5

6

1

2

3

0

ENT

1) Enter the plate width and then press [ENT]. The highlight will move to the plate

length setting.

2) Enter the plate length and then press [ENT].

3) After input is complete, press [SAVE]. The save confirmation screen will appear.

OK

YES

NO

ESC

Save Data ?

4) Press [YES] and then [OK] to save all of the entered information as Plate 1 data.

The data is saved, and the screen returns to the first screen in “5.3 Set plate”.

These keys also move the

highlighted portion.

Plate width

Plate length

5-15

Chapter 5 User menu

5.2.8 Fine adjustment of the image position

Perform fine adjustment (shifting the print area) of the image output position on the

plate.

These keys also move the highlight.

Shift amount in the secondary

scanning (horizontal) direction

Shift amount in the primary

scanning (vertical) direction

1) Enter the desired shift in the secondary scanning (horizontal) direction and then

press [ENT]. The highlight will move to the shift setting in the primary scanning

direction.

2) Enter the desired shift amount in the primary scanning (vertical) direction and

then press [ENT].

3) After input is complete, press [SAVE]. The save confirmation screen appears.

OK

YES

NO

ESC

Save Data ?

4) Press [YES] and then [OK] to save all the information you set as printing machine

1 data. The data is saved and the screen returns to the first screen in “5.3 Set

plate”.

SAVE

ESC

Paper Position H

Paper Position V

0.0 mm

0.0 mm

R

R

CLR

7

8

9

4

5

6

1

2

3

0

ENT

Note: Media Type should have been defined by service during install. If the desired media thickness is not in

the list, contact service. A new Media Type with correct laser and focus settings needs to be created.