First use

1.

Open all air outlets on the compressor.

2.

Connect the plug to the power outlet.

3.

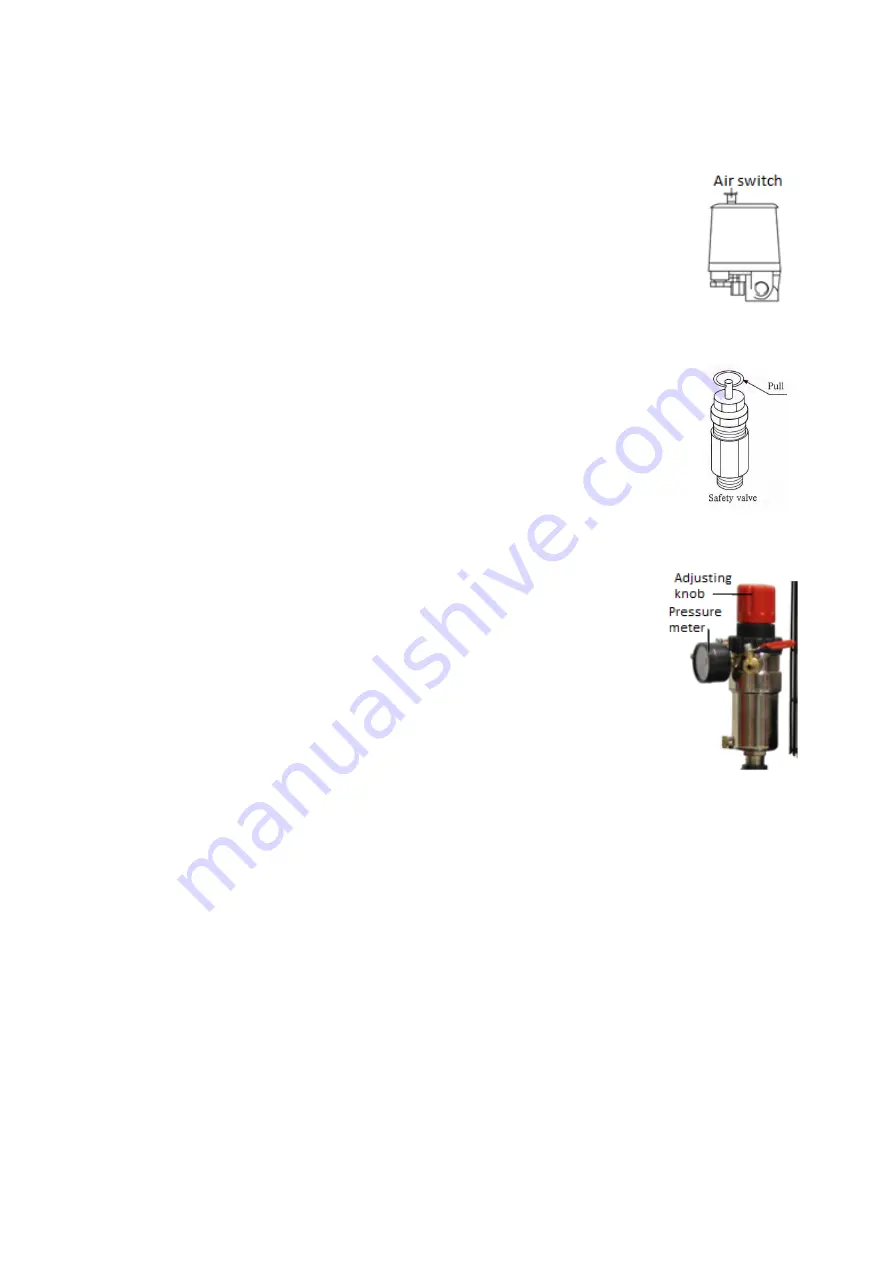

Now pull up the air switch (refer to picture on the right) to start up the

compressor.

4.

Let the compressor run without load for two minutes and listen if the engine

makes any strange sounds. If this is not the case, then close all air outlets.

5.

Check if the compressor is turned off at the maximum pressure of 8 bar.

6.

Now release air from the tank and check if the compressor is turned on

automatically at a pressure of approximately 5bar.

7.

Turn off the compressor by means of the air switch.

PAY ATTENTION! Only

turn the compressor on and off by means of the air switch, the air switch

releases pressure from the lines when turned off, this way the compressor

can start up without load next time.

8.

Check if the safety valve (refer to picture on the right) functions properly by

pulling the ring up, the valve now releases pressure from the tank. Do this

weekly to assure proper functioning of the safety valve.

Operation of the compressor

Before connecting any air tools to the compressor and working with them, you

should check the working pressure of the air tools and then adjust the outlet

pressure on the compressor accordingly by means of the adjusting knob (refer to

picture on the right). You can only adjust the outlet pressure when the

compressor has full pressure, lift the adjusting knob. Turn the knob to the right

to adjust the pressure higher, to lower the pressure turn the knob to the left.

When the correct pressure has been reached, press the adjusting knob down to

set the pressure.

4.

Maintenance

Check previous to each use

1.

Check that all nuts and bolts are tight enough

2.

Check the belt tension and the angle of the belt to the compressor and motor, the angle

should be 90 °, if you can push the belt down 10-15 mm in the middle between the engine

and compressor the tension is good, tighten the belt if necessary. PLEASE NOTE! Both too

much and too little tension on the belt is bad for the compressor!

3.

See if all the pipes look properly and if there is no damage.

4.

Is the oil level correct, this should be up to the red dot in the middle of the oil viewing glass.

5.

Make sure that the electrical wiring is not damaged.

6.

Check the mains voltage and make sure it complies with the machine.

7.

Make sure that the pulley of the belt can be turned round easily.