INSTALLATION AND OPERATING INSTRUCTIONS:

Motor spindle, HF150-003 series

Zimmer GmbH

•

Im Salmenkopf 5

•

77866 Rheinau, Germany

•

+49 7844 9138 0

•

+49 7844 9138 80

•

www.zimmer-group.com

36

EN / 2020-10-22

DDOC00746 / -

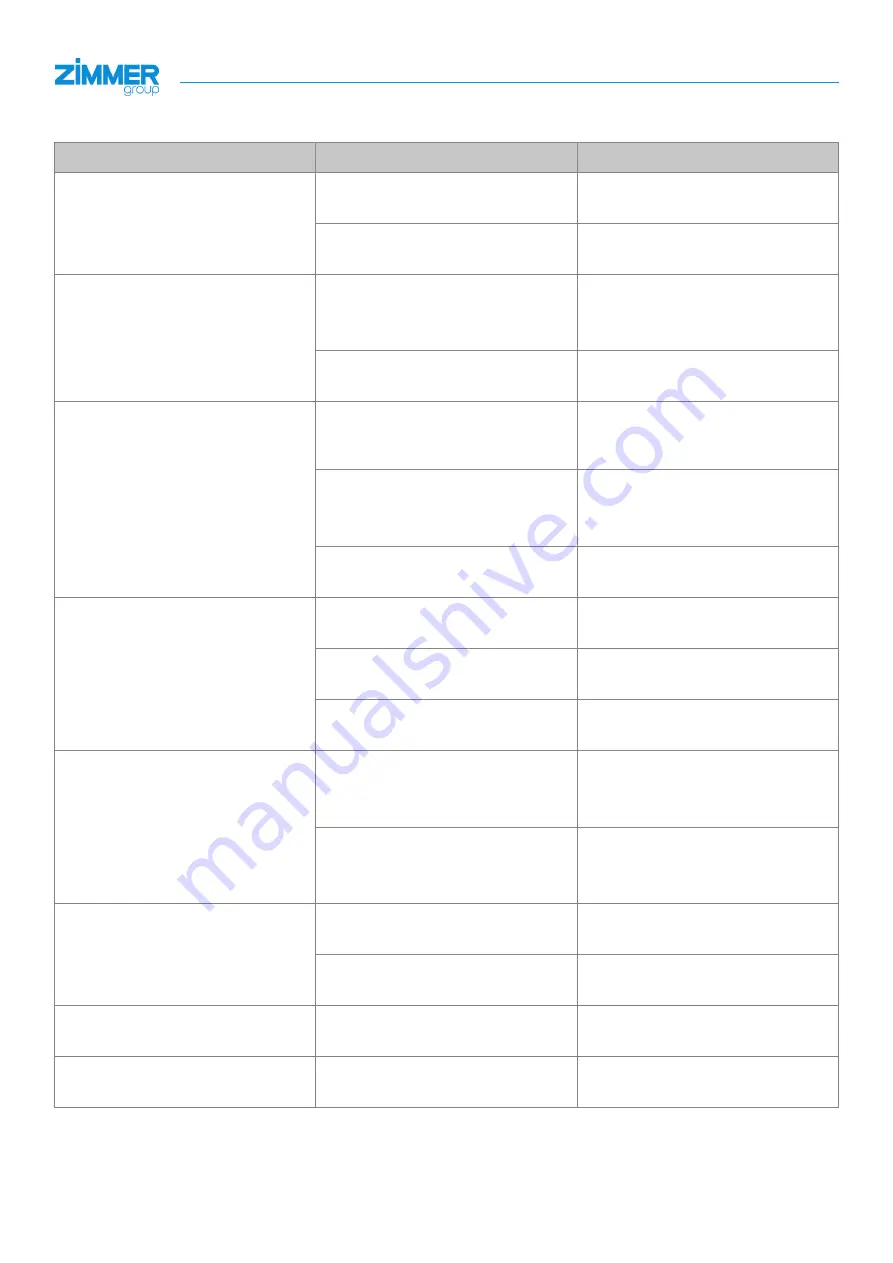

19 Troubleshooting

Error

Possible cause

Measure

Tool or machining unit is not clamped

•

Air supply not OK

►

Check the pneumatic system/

compressed air

• Tool changer of the machine is not

correctly configured

►

Configure tool changer correctly

Motor spindle does not start

•

The tool is not in the motor spindle

►

Replace the tool or unit

►

Check program

•

Air supply not OK

►

Check the pneumatic system/

compressed air

Tool is not unclamped

• Dimension of the tool holder is

outside of tolerance

►

Increase air pressure to the maximum

and try once again

•

Air pressure too low

►

Check air pressure

►

Increase "Release tool" air pressure

•

Water in the cleaning air

►

Install water separator

Temperature sensor in the motor spindle

has responded

•

Cooling system is not switched on

►

Switch on cooling system

• Cooling system is not functional

►

Check cooling system

•

Motor spindle is overloaded

►

Reduce load

Collet chuck status is invalid

•

Motor spindle, tool holder or holder

on the unit are dirty

►

Clean the motor spindle, tool holder

or holder on the unit

•

Tool holder not in accordance with

DIN69893-6

• Dimensions outside of the tolerance

►

Use a tool holder in accordance with

DIN69893-6

Tool holder not retracted correctly

• Plane face is dirty

►

Clean plane face with a clean rag

•

Clamping taper is dirty

►

Clean the clamping taper using a

clean rag

Slight vibration at the motor spindle

• Plane face is dirty

►

Clean plane face with a clean rag

Severe vibration at the motor spindle

• The tool holder is not balanced

►

Balance the tool holder