INSTRUCTION MANUAL

Semi-automatic BOV Filling Machine Z-2323

A0310.02.2323.905.1.EN

Page 24/39

Regulation of proximity sensors placement on actuators

Magnetic proximity sensors are responsible for detecting actuators limit position, what is important

to maintain correctness of algorithm controlling the machine. Magnet is built in actuator piston and

sensor, after detecting it, is generating signal used to control other modules of the device. Wrong

placement of sensor on actuator may generate signal too early (actuator won’t make full scale

movement but sensor will inform about reaching limit position) or stop the machine (actuator has

performed a full scale movement but sensor, which is located too far, won’t detect it).

Correct sensors placement may be checked by observing pneumatic indicator on sensor. Protruded

indicator means that limit position is detected.

Fig. 15. Magnetic proximity sensor SMPO type:

a) indicator hidden back, b) indicator protruded

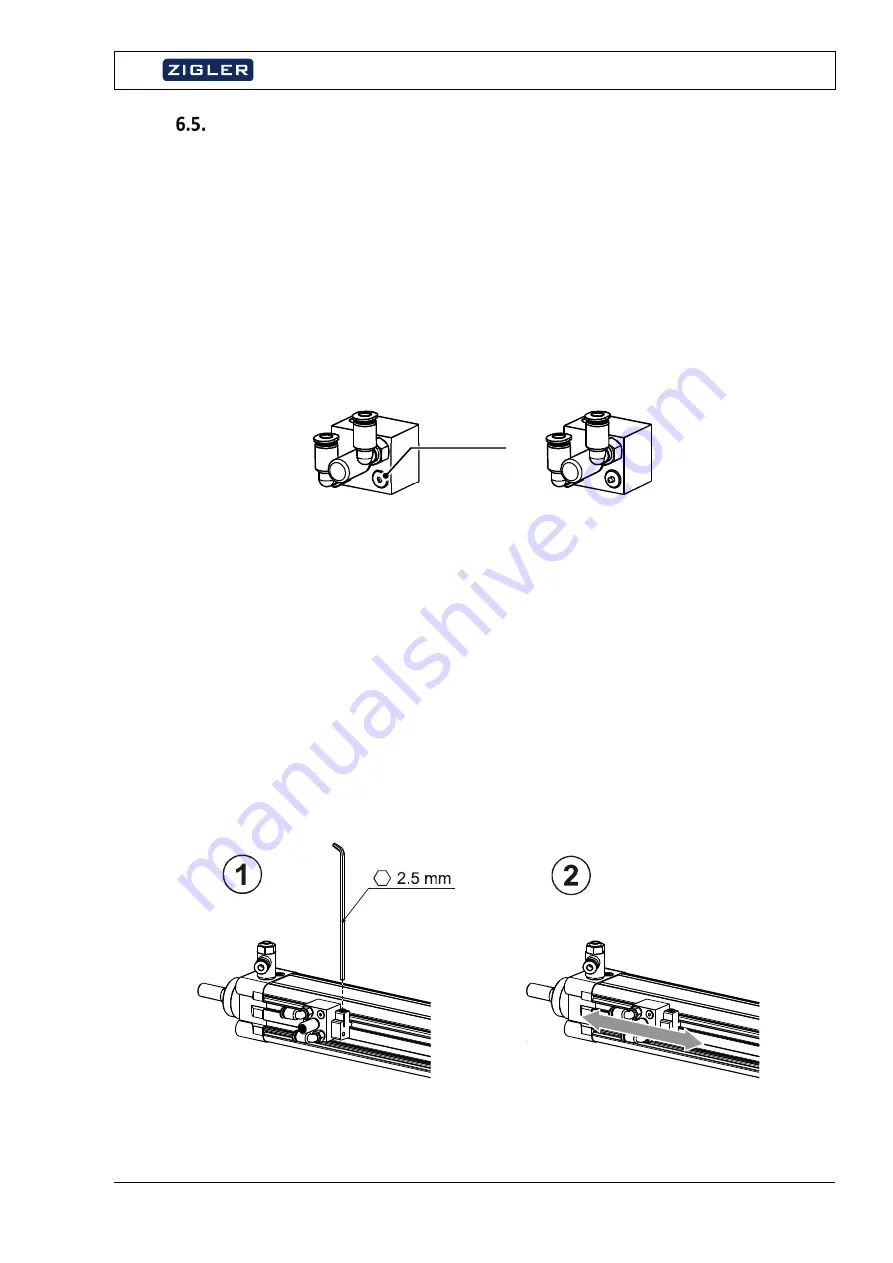

Compressed air supply has to be turned on during proximity sensors regulation. To adjust position

of sensor in square actuator groove it’s necessary to:

Make sure that compressed air supply is turned on and, with the help of 2,5 mm hex key,

untighten the bolt holding sensor (do not unscrew) - Fig. 16, pos. 1.

Move sensor along groove in actuator body to appropriate position - Fig. 16, pos. 2. It’s

necessary to observe pneumatic indicator – it should move forward when limit position is

detected.

To block sensor placement tighten up the bolt.

Fig. 16. Regulation of proximity sensor placement in actuator groove

a)

b)

Pneumatic

indicator

Summary of Contents for Z-2323

Page 42: ...PNEUMATIC DIAGRAMS ...