4

Mounting

4.1

General notes

Attention!

•

Mounting is only to be undertaken by trained service personnel. The system manufacturer or the

machine builder and/or the user is responsible that the inherent installation and security information

are harmonized with the valid standard and guidelines (EN ISO12100 / 13857).

•

Check the fan for damage, e.g. cracks, dents or damage to the electric cables, before assembly.

Start-up is not allowed in the case of transport damage!

•

Wear safety clothing / shoes and cut-resistant safety gloves when handling.

•

At a weight greater than 25 kg for men / 10 kg for women, the fan should be lifted out by two persons

(according to REFA). The values may differ from country to country.

•

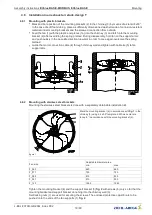

Lift the fan out of the packaging with a lifting gear (lifting beam). Attachment points are solely the

holes on the housing

fl

ange, motor bed, support plate, motor suspensions, fastening brackets and

any crane eyes of the fan (depending on the design of the fan).

•

The chain/rope may not touch the impeller and the possibly mounted frequency inverter when lifting

with the lifting beam, otherwise damage is possible.

•

The custom designs must suit the prevailing conditions.

•

Take into account easy access for cleaning and maintaining the fan.

•

Before installing the fan, make sure the safety distances are maintained compliant with EN ISO

13857 or in household equipment according to EN 60335.

–

If the mounting height (danger area) above the reference plane is greater than or equal to

2700 mm and is not reduced by auxiliary means such as chairs, ladders, working platforms or

fl

oor space on vehicles, a guard grille is not necessary on the fan.

–

If the fan is located in danger zone, then the manufacturer or operator shall ensure that hazards

shall be prevented by appropriare protective constuctions which meet the requirements to EN ISO

13857.

•

Protective measures must be taken against falling parts when mounting with a hanging rotor.

•

Tighten the fastenings with the speci

fi

ed torques.

•

Drilling chips, screws and other foreign bodies must not be located inside the device! Before the

fi

rst

switch-on, remove any items that may be present (drilling chips, screws and other foreign objects)

from the intake area - risk of injury from any objects that may

fl

y out!

•

For fans, the alignment must be adhered to during operation, e.g. if this is indicated by

“

Oben/Top

”

.

4.2

Connection lead & terminal box

•

In demanding environments (wet rooms, outdoor installation), connecting cables must have water

draining pipe elbows.

•

If using a terminal box, install this lower than the motor to ensure that water cannot penetrate

through to the controller housing from the connecting cables.

Do not coat connection components!

Coating connecting cables, cable glands and electronics covers (e.g. by paint-

ing, lacquering, powder-coating), is not permissible without consulting

ZIEHL-ABEGG!

Assembly instructions

ECblue BASIC-MODBUS, ECblue BASIC

Mounting

L-BAL-F079D-GB 2044 Index 002

Part.-No.

15/80